240005126 Rev A 10/27/2005

11

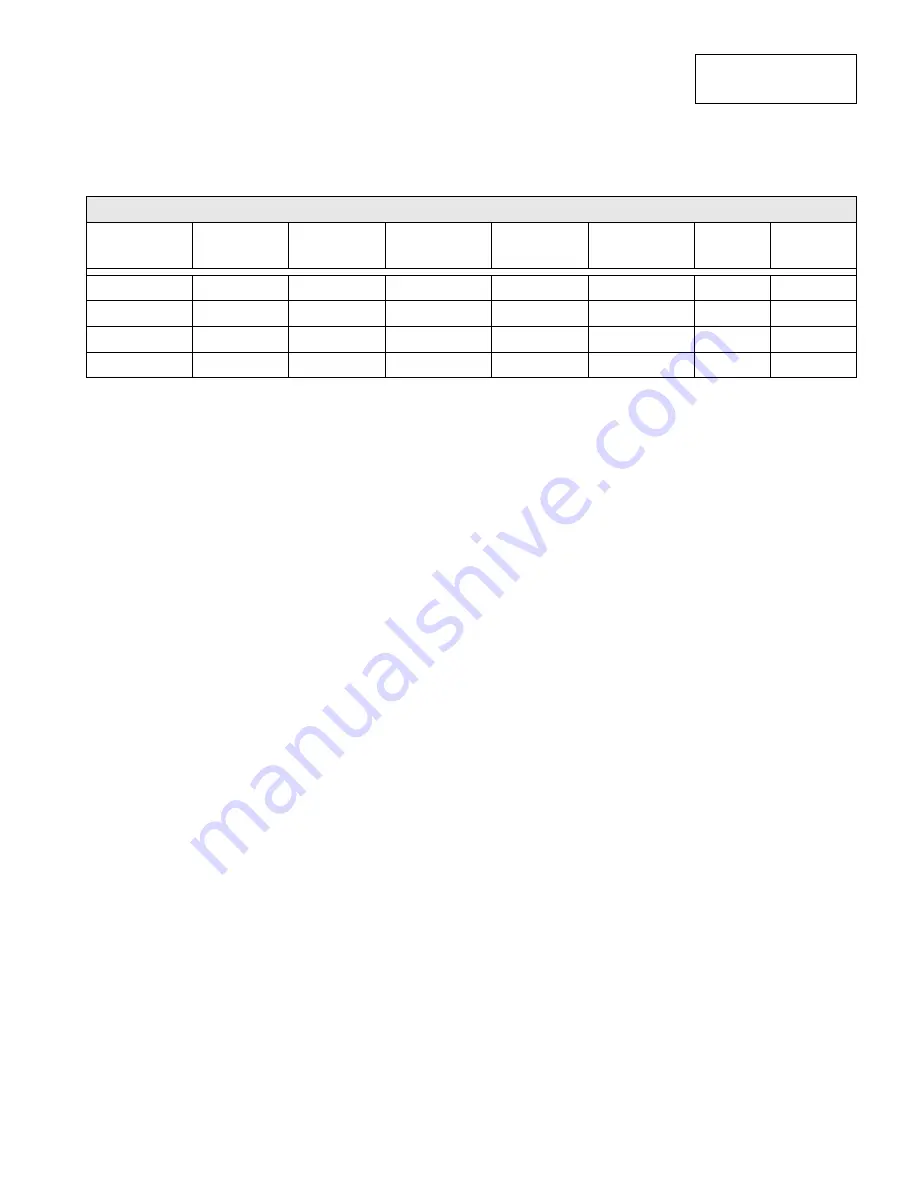

Burner information for the HTL series furnace.

Table A-1 Beckett AF Oil Burner Set-Up

Beckett AF Series Oil Burner

Furnace

Model

Output

BTU/Hr

Burner

Model

Nozzle

Pump

Pressure

Flow Rate

Head

1

Static

Plate

HTL-80C

79,000

AF65XN

0.65 / 80°A

100

PSIG

0.65

USGPH

F3 2-¾

in.

HTL-90C

90,000

AF65XN

0.75 / 80°A

100

PSIG

0.75

USGPH

F3 2-¾

in.

HTL-100C

101,000

AF65XN

0.85 / 80°A

100

PSIG

0.85

USGPH

F3 2-¾

in.

HTL-120C

119,000

AF65XN

1.00 / 60°A

100

PSIG

1.00

USGPH

F3 2-¾

in.

A.1 OIL BURNER AIR ADJUSTMENT

For complete details, consult the oil burner instruction

manual provided in the furnace documents envelope.

Beckett AF Burner

Adjust the air shutter by loosening the locking screws

and moving the air shutter, and if necessary, the bulk

air band.

A.2 BURNER ELECTRODES

Adjustment of the electrode tips with respect to each

other, the nozzle, and to the rest of the burner is very

important to ensure smooth start-ups and to permit

efficient combustion.

Beckett AF Burner

Electrode gap: 5/32 inch.

Distance above horizontal centerline: 5/16 inch. Older

instruction sheets specify 7/16 inch. The current

specification is 5/16 inch.

Distance ahead of nozzle: 1/16 inch.

“Z” dimension, the distance from the front of the end

cone (head) to the face of the nozzle should be 1-1/8

inches. If a ceramic head is used, the distance from

the end cone to the nozzle face is increased to 1-3/8

inches.

A.3 START UP

The furnace should be operated for a minimum of 15

minutes to reach steady state conditions before fine

tuning combustion. The warm up time is ideal for

testing the oil pump pressure.

Drill a 1/4-inch test port in the venting between the

furnace flue outlet and draft regulator (barometric

damper). Insert a stack thermometer and note the flue

gas temperature. The flue gases should be within a

range of 350°F to 450°F. If the flue gases are below

the range, it may be necessary to slow down the

blower fan. If the flue gases are above the range, the

blower fan may require speeding up. Stack

temperature varies directly with the system

temperature rise. System temperature rise is the

difference between the furnace outlet temperature and

furnace inlet temperature as measured in the vicinity of

the connection between the plenum take-offs and the

trunk ducts. Typical temperature rise values range

between 65°F and 95°F.

Perform a smoke spot test. The smoke spot should not

exceed No. 1 on the Bacharach Scale.

After the air adjustments have been completed, re-

check the draft pressure at the furnace burner

mounting plate The draft should be adjusted to 0.02

inches w.c.

In the United States, the Beckett AF Burner may be

equipped with Beckett's "

Inlet Air Shut-Off

" to increase

efficiency. (Beckett Part No. AF/A 5861).

NOTE: USE OF THE INLET AIR SHUT-OFF COULD

CAUSE POST COMBUSTION NOZZLE DRIP

RESULTING IN HIGHER SMOKE LEVELS AND

PREMATURE SOOTING OF THE HEAT

EXCHANGER.

Appendix A

HTL-C