Dehumidifi cation:

For situations where humidity control is a problem, a dehumidifi ca-

tion feature has been built into the variable speed motor. At the start

of each cooling cycle, the variable speed motor will run at 82% of

the rated airfl ow for 7.5 minutes. Aft er 7.5 minutes has elapsed, the

motor will increase to 100% of the rated airfl ow. If this feature is not

desired, clip the jumper wire between Y and O on the integrated

furnace control board. With Y and O not jumpered, the variable

speed will reach 100% of the rated airfl ow within 10 seconds of a call

for cooling.

Additional dehumidifi cation can be achieved by connecting a hu-

midistat to the DEHUM and R terminals on the integrated furnace

control board. In this setup, the variable speed motor will operate at

a 10% reduction in the normal cooling airfl ow rate when there is a

call for dehumidifi cation.

Both dehumidifi cation methods described above can be utilized on

the same furnace.

Setting Blower “On” And “Off ” Timings

Blower on/off delays are handled by ECM

motor programming. Th

e control de-energizes the ECM heat signal

when the gas valve de-energizes. Features of this ECM variable speed

motor are that it will deliver a constant airfl ow within a wide range

of external static pressures, and also includes:

Soft Start:

This ECM variable speed motor will slowly ramp

up to the required operating speed. This feature in the heating

cycle allows the heat exchanger to reach operating tempera-

ture before the set heat speed, which minimizes noise and

increases comfort.

Soft Stop:

At the end of the heating or cooling

cycle, the ECM variable speed motor will slowly ramp down.

This feature allows for increased

energy ef

fi

ciency, and reduced noise levels.

Continuous Fan Operation

When the thermostat continuous fan (G) switch is on without a call

for heat or cooling, the indoor fan is immediately energized up to

50% of the cooling speed. Th

e fan remains energized as long as the

call for fan remains without a call for heat or cooling. Th is feature

allows continuous circulation of air between calls for heating or

cooling.

If a call for heat (W) occurs during continuous fan, the blower will

de-energize.

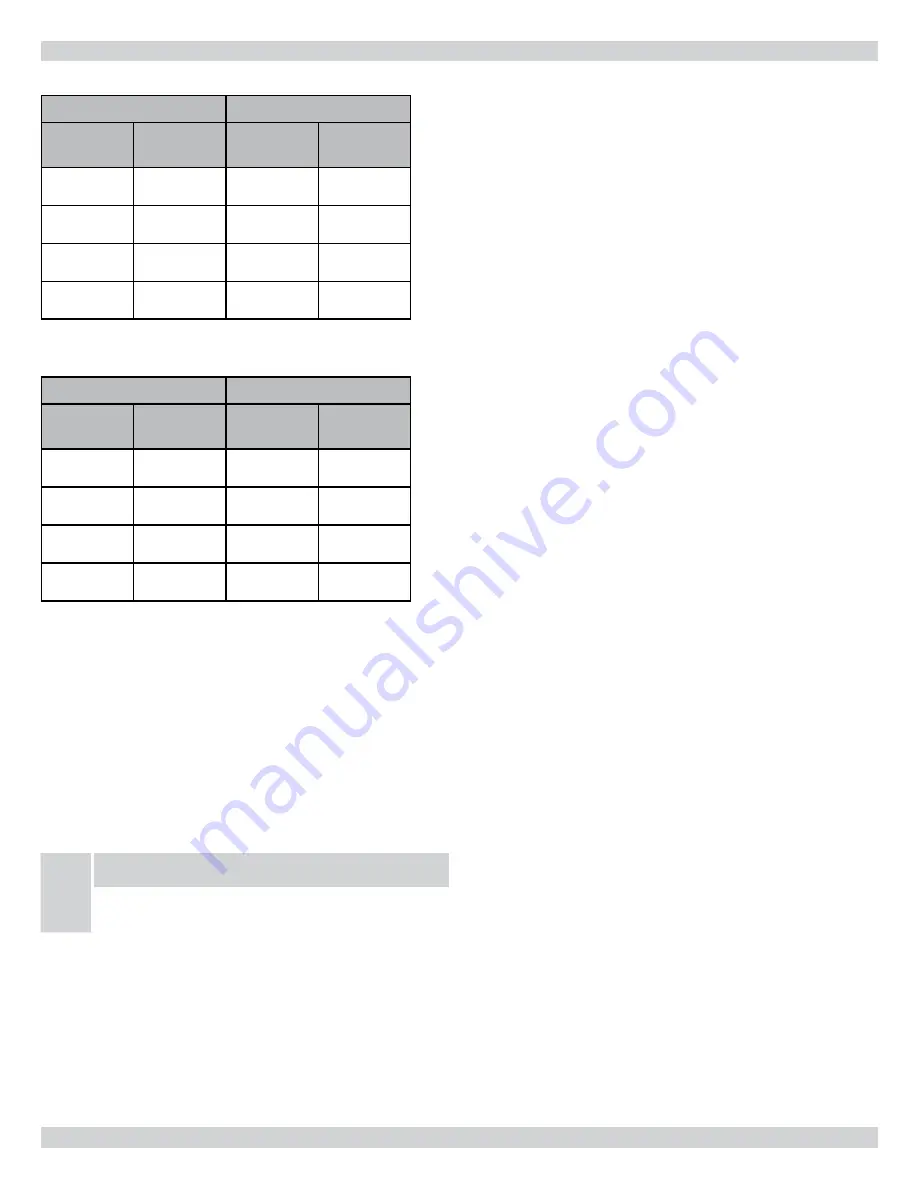

TABLE 11E HEATING CFM

95V080-3

ESP 0.1” to 1.0” w.c.

HEAT

Jumper

ADJUST

Jumper

Low-Fire

CFM

High-Fire

CFM

A

NORM

1050

1376

B

NORM

1250

1400*

C

NORM

900

1242

D

NORM

780

1108

* Motor CFM maximum\

TABLE 11E HEATING CFM

95V100-5

ESP 0.1” to 1.0” w.c.

HEAT

Jumper

ADJUST

Jumper

Low-Fire

CFM

High-Fire

CFM

A

NORM

1200

1620

B

NORM

1400

1820

C

NORM

1100

1474

D

NORM

950

1349

Note: Moving the ADJUST jumper from the NORM position to the

(+) or (-) position will increase or lower the temperature rise

by 15%

If the blower speeds require adjustment, follow these steps:

1.

Remove the blower compartment door.

2.

Locate the 4 position movable HEAT jumper to adjust heat

speed.

3.

Remove the jumper from position A

and place it on the corresponding letter B, C,

or D as required. Refer to

TABLE 11A-11E HEATING-

SPEEDS.

NOTICE

NOTE: Temperature rise should always be re-checked

whenever blower speed is changed.

4.

To adjust the cooling airfl ow, remove the COOL jumper from

position A and place it on the corrosponding letter B, C, or D.

Refer to

TABLE 10 AIR FLOW

.

Moving the ADJUST jumper from the NORM to the (+) or (-) posi-

tion will cause the airfl ow to be increased or lowered by 15%.

Th

e TEST position on the ADJUST tap is not used.

23 - AIR FLOW

46