!

CAUTION

Failure to follow all venting guidelines may result in erratic

furnace operation, freeze-up of the exhaust air piping, or

sooting of the furnace.

!

WARNING

READ AND FOLLOW ALL INSTRUCTIONS IN THIS

SECTION. FAILURE TO PROPERLY VENT THIS FUR-

NACE CAN CAUSE CARBON MONOXIDE POISON-

ING OR AN EXPLOSION OR FIRE RESULTING IN

PROPERTY DAMAGE, PERSONAL INJURY OR LOSS

OF LIFE.

NOTICE

NOTE: Combustion air intake and exhaust termination

should be inspected periodically to ensure they are clear of

obstructions. i.e. vegetation, debris, snow, etc.

NOTICE

NOTE: Accumulation of snow around the combustion air

intake and exhaust termination may have negative eff ects

on appliance operation and/or performance. Snow accu-

mulation should be considered when locating combustion

air intake and exhaust terminations.

• Venting may be vertical or horizontal.

• Minimum vent length - 25 total equivalent feet.

(See

Venting Table6)

• Horizontal piping must slope back towards the furnace at a

minimum rate of ¼” to the foot, so that condensate drains

towards the furnace.

• Horizontal runs must be supported at least every 3 feet.

Horizontal sections must not dip or sag.

• All vent runs through unconditioned space where freezing

might occur should be insulated with 1” thick, medium

density, foil-faced Fiberglass insulation. An equivalent

“arm-a-fl ex” or “rub-a-tex” may also be used as long as

there is no heat tape applied to the vent pipe. For horizon-

tal runs where water may collect, wrap the vent pipe with

self regulating 3 or 5 watt heat tape. Th

e heat tape must

be CSA, UL, or ULC listed and installed per the manufac-

turer’s instructions.

• DO NOT COMMON VENT WITH ANY OTHER APPLI-

ANCE.

• If venting vertically, do not vent up a chimney serving

another appliance or install in a chase with a metal or high

temperature plastic pipe from another gas or fuel burning

appliance unless the required clearances to combustibles

can be maintained between the furnace venting system and

other pipes.

All exhaust piping must be installed in accordance with CAN/CGA-

B149.in Canada; the latest edition of National Fuel Gas Code, NFPA

54 / ANSI Z223.1 in the United States, as well as in accordance with

local codes.

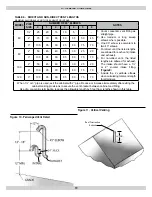

Size the combustion air and exhaust piping in accordance with

Table 6

. When calculating allowable vent lengths, be sure to count

all termination fi ttings in addition to counting the concentric vent as

a straight pipe.

Take the building orientation and the presence of other buildings

or other nearby structures into consideration when planning the

venting system location. Certain external structures could create air

turbulence around the vent termination leading to downdraft s and

similar venting problems. In windy and hill locations, roof venting

may improve operations. Maximum venting length is based on 30

mph winds, areas where higher gusts are dominant it is suggested to

shorten the horizontal vent length.

Th

e vent and combustion air intake shall be installed so that both are

located in the same wind pressure zone.

!

WARNING

DO NOT CONNECT FURNACE TO A CHIMNEY OR

FLUE SERVING OTHER APPLIANCES OR A SOLID

FUEL BURNING APPLIANCE.

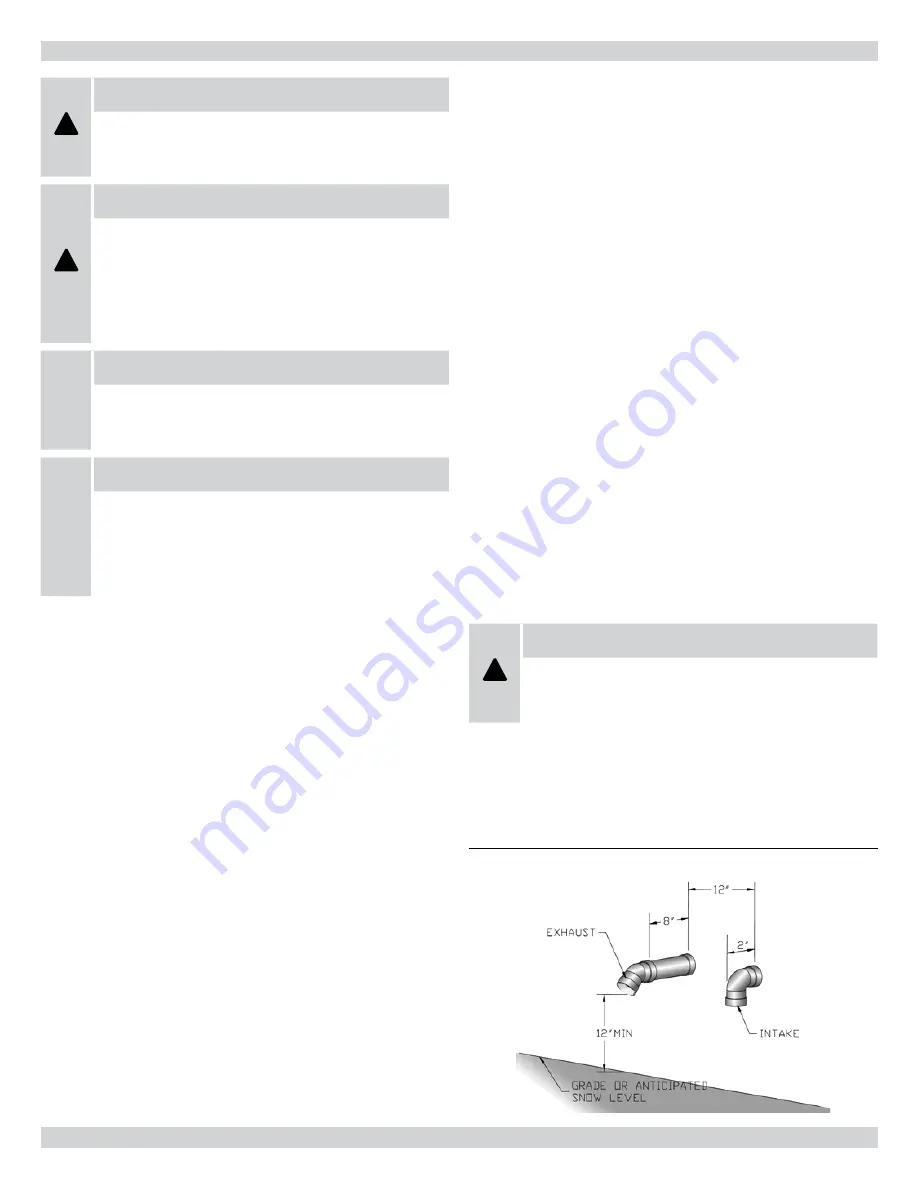

Vent Termination

Horizontal vents should pass through the exterior wall.

Figure 9

shows a standard horizontal vent detail. Terminate the vent approxi-

mately 8” or more from the wall.

12 - VENTING GUIDELINES

Figure 9 - Standard (Straight) Horizontal Vent Detail

18