NOTICE

IMPORTANT: If an air conditioning evaporator coil drain

is to share the furnace drain line, it should be connected

with a tee fi tting downstream from the trap. Do not con-

nect the evaporator coil condensate drain upstream of the

furnace drain trap assembly.

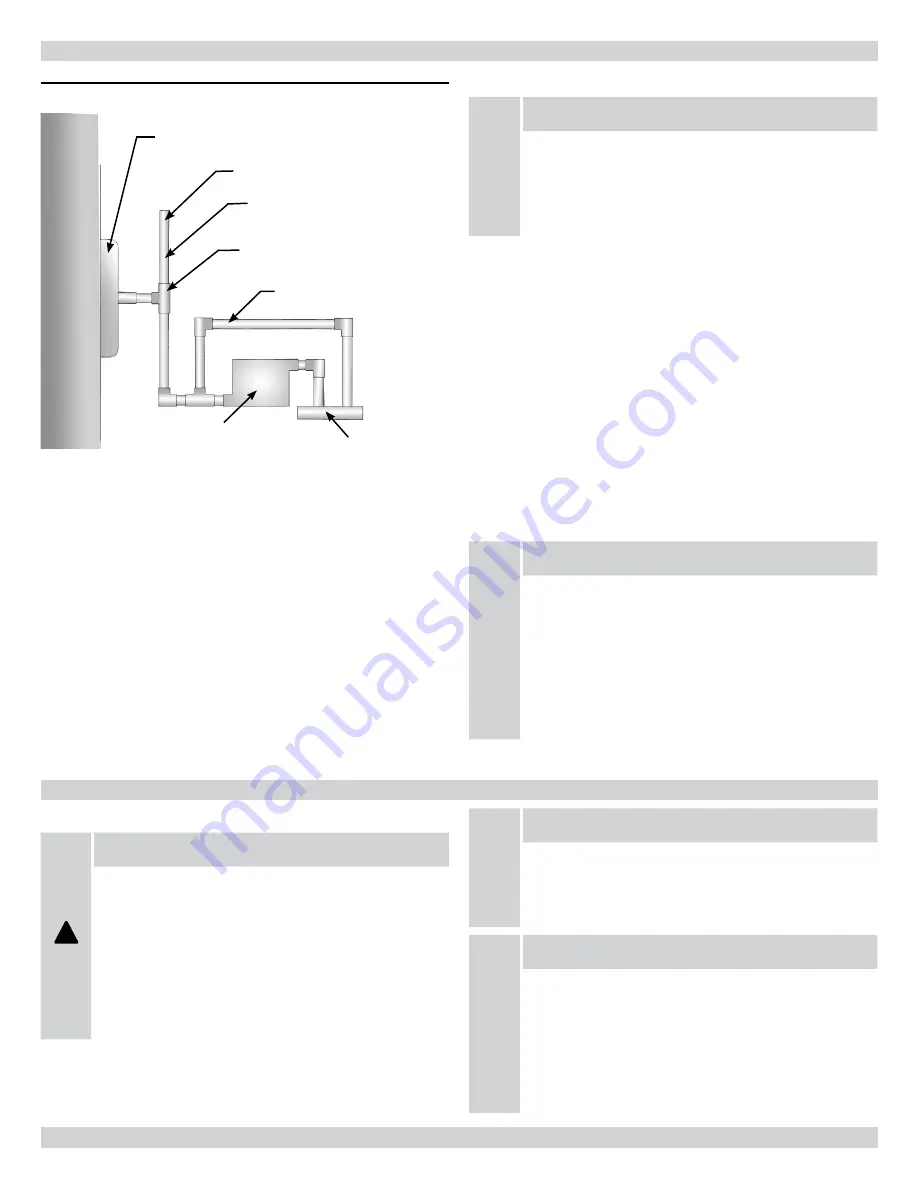

Condensate Neutralizers

Some local codes may require the use of a condensate neutralizer. If

the furnace condensate is to be routed to a septic system, it may be

advisable to use a condensate neutralizer.

Condensate neutralizers such as the Ward Industries 90+ Neutralizer

are available through heating supply wholesalers.

When condensate neutralizers are used, it is advisable to install it

with an overfl ow bypass tube. (

Figure 27)

NOTICE

IMPORTANT: Th

e condensate drain trap assembly should

be full of water before starting the furnace. To fi ll the con-

densate drain trap assembly, temporarily remove the vent

drain hose from the induced blower assembly elbow/drain

fi tting, and pour approximately one cup of water down the

hose. Water will begin running out the condensate drain

trap outlet when it is full. Refasten the vent drain hose to

the induced blower assembly elbow/drain fi tting.

Figure 27 - Condensate Bypass

G95V

UNIT

OLSEN DRAIN TRAP

ASM

VENT

1/2" PIPE

& FITTINGS

NEUTRALIZER BYPASS

CONDENSATE NEUTRALIZER

(IF REQUIRED)

DRAIN

VENT HEIGHT MUST BE 1"

ABOVE RECOVERY COIL

Th

e condensate drainage confi guration requires a vent. It takes less

than a one inch rise anywhere along the horizontal route of the drain

tube to create a vapor lock, which will prevent condensate from

draining away freely, and result in erratic furnace operation.

A typical confi guration would be to cement the side branch of a ½”

PVC tee to the drain trap assembly outlet, with the end branches

oriented vertically. (

Figure 27

)

A 1” piece of ½” PVC pipe cemented to the upper end branch will

serve as a vent, which will prevent the creation of a vapor lock,

and serve as an overfl ow in the event that the drain line becomes

blocked. A similarly sized piece of pipe cemented to the lower end

branch will permit connection to the condensate outlet with ⅝” ID

/ ⅞” OD fl exible tubing, or the condensate may be piped entirely in

PVC to the fl oor drain/sump/condensate pump.

16 - CONDENSATE DRAINS

Gas Supply

!

WARNING

THIS FURNACE IS FACTORY EQUIPPED TO BURN

NATURAL GAS ONLY.

CONVERSION TO LP GAS REQUIRES SPECIAL NATU-

RAL GAS TO LP CONVERSION KIT.

FAILURE TO USE THE PROPER CONVERSION KIT

CAN CAUSE FIRE, EXPLOSION, CARBON MONOX-

IDE POISONING, PROPERTY DAMAGE, PERSONAL

INJURY OR LOSS OF LIFE.

NOTICE

IMPORTANT: Conversion of this furnace requires

specialized equipment. Conversion must be completed

by a trained and qualifi ed installer, service agency or gas

supplier.

NOTICE

IMPORTANT: Connect this furnace only to gas supplied

by a commercial utility or supplier. Private gas wells do not

generally provide gas with consistent, uniform and pre-

dictable heating values and densities. Many non-commer-

cial wells contain impurities such as sulphur, which may

damage the furnace. Th

is furnace cannot operate properly

or safely using fuels outside normal commercial standards.

17 - GAS SUPPLY AND PIPING

34