For proper furnace operation, air fl ow over the heat exchanger is of

utmost importance. Insuffi

cient airfl ow accelerates metal fatigue and

failure in the heat exchanger and excessive airfl ow promotes acceler-

ated corrosion of the heat exchanger.

NOTICE

IMPORTANT: Do not bypass this step of the start up

procedures.

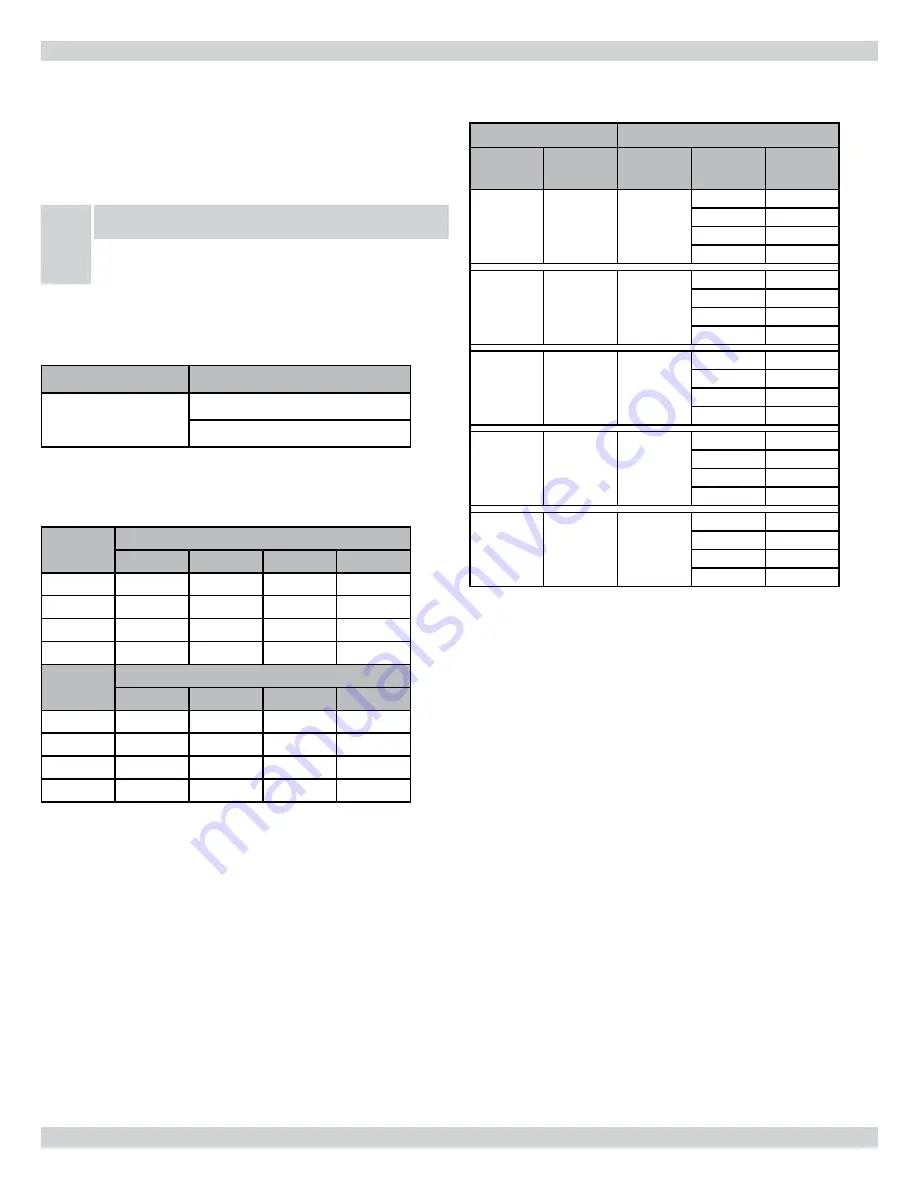

TABLE 1A - RANGE OF TEMPERATURE RISE

Furnace Model

Temperature Rise

60, 80, 100, 120

High Fire (HF) 35 - 65°F

Low Fire (LF) 25 - 55°F

TABLE 1B - AIR FLOW FOR TEMPERATURE RISE

Furnace

Model

High Fire (HF) CFM Required for a

▲

T of:

35

45

55

65

60

1501

1167

955

808

80

2001

1557

1274

1078

100

2502

1946

1592

1347

120

3002

2335

1910

1616

Furnace

Model

Low Fire (LF) CFM Required for a

▲

T of:

25

35

45

55

60

901

700

573

485

80

1201

934

764

647

100

1501

1167

955

808

120

1801

1401

1146

970

Temperature Rise Check

When the duct system is complete and the air fi lter or fi lters are in

place, determine if the airfl ow is correct for both low and high fi re

input rates..

1.

Insert a duct thermometer in the supply air duct. Th

e thermom-

eter should be placed as close as practical to the furnace, but out

of the “line of sight” of the heat exchanger (this prevents false

readings owing to radiant heat). Ensure that the thermometer

location is within the duct air stream. Avoid locations such as

the inside radius of an elbow, etc.

TABLE 10 - AIR FLOW

MODEL 95V

ESP 0.1” to 1.0” w.c.

Input

A/C

Tonnage

ADJUST

Jumper

COOL

Jumper

CFM

60000

3 Ton

NORM

A

1200

B

1000

C

800

D

600

80000

3 Ton

NORM

A

1200

B

1000

C

800

D

600

80000

4 Ton

NORM

A

1600

B

1200

C

1000

D

800

100000

5 Ton

NORM

A

2000

B

1600

C

1200

D

800

120000

5 Ton

NORM

A

2000

B

1600

C

1200

D

800

Note: Moving the ADJUST jumper from the NORM position to the

(+) or (-) position will increase or lower the CFM by 15%

2.

Insert a duct thermometer in the return air duct as close to the

furnace as practical. Ensure that the thermometer location will

be unaff ected by humidifi er bypass ducts, etc. Choose a location

well within the main air stream.

3.

Operate the furnace long enough to obtain steady state condi-

tions at both input rates (High Fire and Low Fire).

4.

When the two thermometers have stabilized, usually within

5-8 minutes, compare the two readings. Subtract the return air

temperature from the supply air temperature. Th

e diff erence is

the temperature rise, also called ΔT.

5.

Compare the measured ΔT to the temperature rise range shown

on the rating plate. Unless stated diff erently on the rating plate,

the temperature rise should normally range between 35° to 65°F

High Fire, 25° to 55°F Low Fire. When adjusting the tempera-

ture rise, the ideal temperature is approximately mid-range.

If the measured ΔT is above the approved temperature range,

there is too little air fl ow. It must be increased by selecting the

appropriate “HEAT” jumper setting , removing restrictions

in the ductwork, or adding supply or return

ductwork.

If the measured

∆

T is too low, there is too

much air

fl

ow.

23 - AIR FLOW

44

![Roberts Gorden Combat UHD[S] 150-400 Specifications preview](http://thumbs.mh-extra.com/thumbs/roberts-gorden/combat-uhd-s-150-400/combat-uhd-s-150-400_specifications_1469644-1.webp)