!

WARNING

DISCONNECT THE ELECTRICAL POWER SUPPLY TO

THE FURNACE BEFORE ATTEMPTING ANY MAIN-

TENANCE. FAILURE TO DO SO CAN CAUSE ELEC-

TRICAL SHOCK RESULTING IN PERSONAL INJURY

OR LOSS OF LIFE.

!

CAUTION

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and dangerous

operation.

Always verify proper operation aft er servicing.

Air Filter

Th

e fi lter should be inspected frequently and cleaned as necessary.

We recommend a monthly inspection at fi rst, perhaps coinciding

with the arrival of the monthly fuel bill as a reminder. Th

e frequency

may be increased or decreased depending on experience and condi-

tions.

Avoid the use of the fi berglass throw-away fi lters. Th

ey tend to block

up quickly, which may result in higher than normal operating tem-

peratures, and lower effi ciency.

Some paper media high effi

ciency fi lters, sometimes identifi ed as

HEPA fi lters can do an eff ective and excellent fi ltration of the air;

however, some models may also cause a large pressure drop across

the fi lter. Th

e contractor should assess the capabilities of the duct

system to deliver suffi

cient air fl ow if this type of fi lter is considered.

Recommended:

Electronic air fi lters using electrostatic precipita-

tion to remove dust are an excellent fi ltration device. A 16” x 25”

model is an ideal fi t with this furnace in the case of a side mounted

return air inlet. Th

e furnace control module is supplied with electri-

cal terminals for use with electronic air cleaners.

A 16” x 25” x 1” fi lter kit part number 550001458 can be ordered for

use on this appliance. Th

is kit includes the fi lter rack and washable

fi lter.

NOTICE

NOTE: If two return air inlets are used, both must be

equipped with fi lters.

!

CAUTION

Do not operate the furnace for prolonged

periods of time without an air

fi

lter.

A portion of the dust entrained in the air

may lodge in the supply air ductwork and

registers. Any recirculated dust particles

will be heated and charred by contact with

the furnace heat exchanger. This residue

will soil ceilings, walls, drapery, carpets,

and other household articles.

If a call for cool (Y) occurs simultaneously with the call for fan (G),

the call for cool overrides the call for fan and the blower remains off

for the cooling on delay period.

23 - AIR FLOW

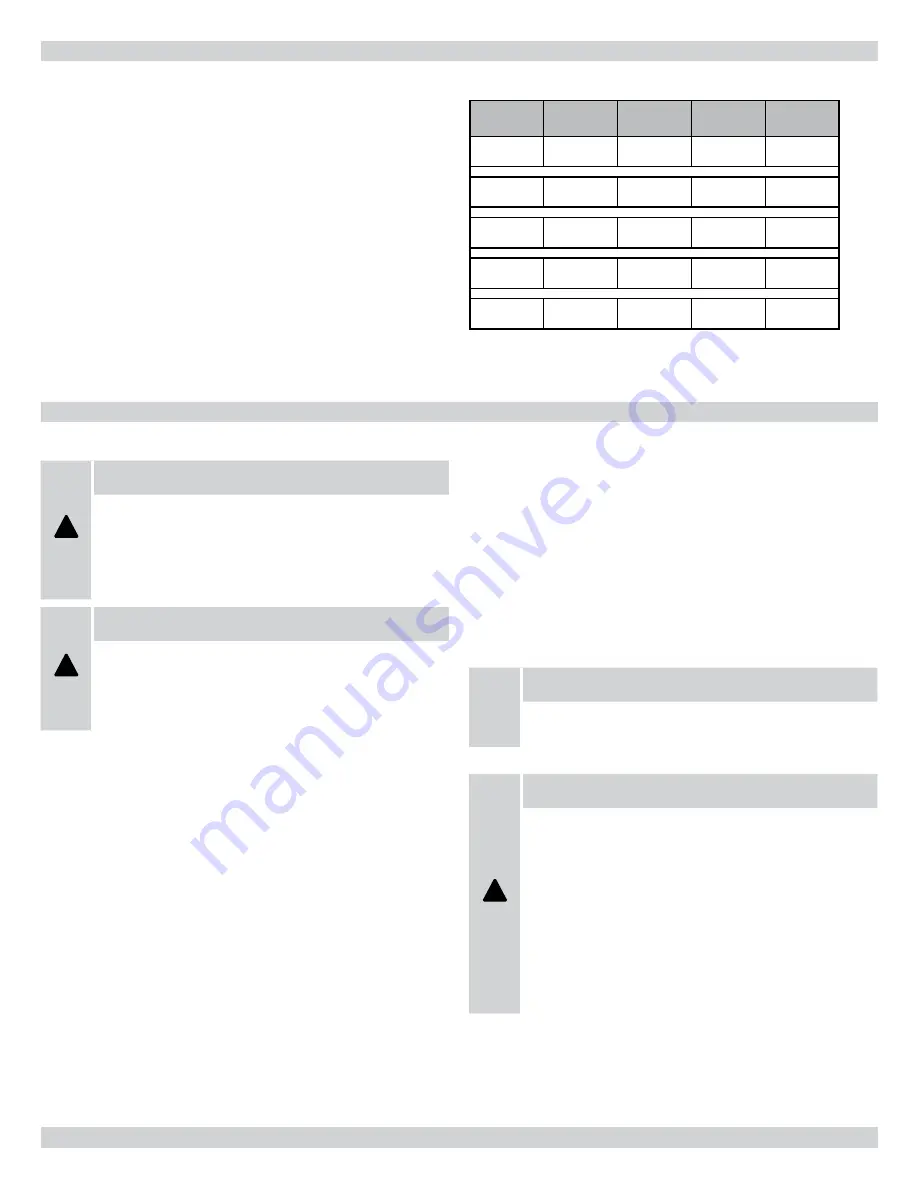

TABLE 12 - CONTINUOUS FAN CFM

MODEL

Motor

HP

COOL

Jumper

ADJUST

Jumper

Continuous

Fan (CFM)

95V060-3

1/2

A

NORM

600

95V080-3

1/2

A

NORM

600

95V080-4

3/4

A

NORM

825

95V100-5

1

A

NORM

865

95V120-5

1

A

NORM

930

Note: Moving the ADJUST jumper from the NORM position to the (+)

or (-) position will increase or lower the continuous fan CFM by 15%

24 - MAINTENANCE AND TROUBLESHOOTING

47