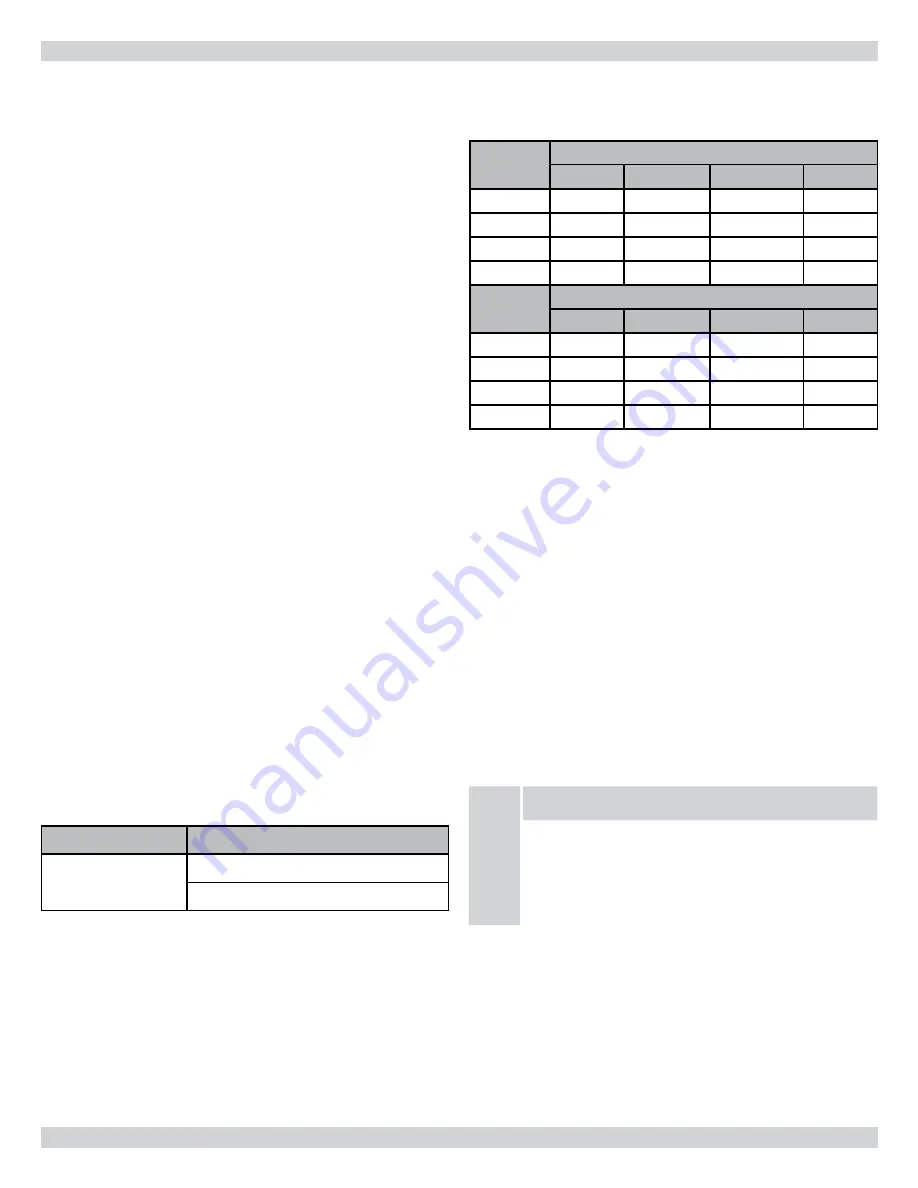

TABLE 3B - AIR FLOW FOR TEMPERATURE RISE

Furnace

Model

High Fire (HF) CFM Required for a

▲

T of F

35

45

55

65

60

1501

1167

955

808

80

2001

1557

1274

1078

100

2502

1946

1592

1347

120

3002

2335

1910

1616

Furnace

Model

Low Fire (LF) CFM Required for a

▲

T of F

25

35

45

55

60

901

700

573

485

80

1201

934

764

647

100

1501

1167

955

808

120

1801

1401

1146

970

Existing ductwork should be assessed for its air handling capabili-

ties. For residential applications, the recommended air velocity of

a supply air trunk duct is 700 feet per minute (fpm), and should

not exceed 900 fpm. Th

e recommended air velocity of a supply air

branch run is 600 fpm, and should not exceed 900 fpm. Th ese values

are slightly lower for fl exible ducting. Th

e recommended air veloc-

ity of a return air trunk duct is 600 fpm, and should not exceed 700

fpm. Th

e recommended and maximum air velocity of a return air

branch 600 fpm.

Th

e “Equal Friction Chart,” as published by ASHRAE and HRAI, is

the basis for the various air duct calculators available through heat-

ing supply companies. Following the air velocity guide lines, accord-

ing to the “Equal Friction Chart,” or a slide rule air duct calculator, a

typical 6” round duct has a capacity of approximately 100 cfm.

NOTICE

Th

e return air system is equally as important as the supply

air system. An under-sized return air system will prevent

suffi cient quantities of air from reaching the supply air

system and will consequently reduce the service life of the

furnace and its components.

4 - FURNACE SIZING

Furnace Sizing

Th

e maximum hourly heat loss for each heated space shall be calcu-

lated in accordance with the procedures described in the manuals of

the Heating, Refrigeration and Air Conditioning Institute of Canada

(HRAI), or by any other method which is suitable for local condi-

tions, provided the results obtained are in substantial agreement

with, and not less than those obtained using the procedure described

in their manuals.

In the United States, “Manual J - Load Calculation,” published by

the Air Conditioning Contractors of America, describes a suitable

procedure for calculating the maximum hourly heat loss.

If the installation is a retrofi t application, do not rely on the capac-

ity of the existing heating equipment as a method to size the new

furnace. Many of the heat transfer multiples listed in earlier versions

of load calculation manuals were much higher than those listed in

more recent editions. It is possible that energy saving measures have

been completed since the installation of the existing furnace. Th is

might include additional insulation in the attic or walls, the applica-

tion of sprayed foam insulation, the addition of storm windows and

doors, weather-stripping, caulking, etc.

Many of the older furnaces were equipped with large belt drive blow-

er systems, operating at low RPM’s. If replacing an existing furnace,

be sure that the existing ductwork can handle the amount of airfl ow

necessary for a reasonable temperature rise. Most older gas furnaces

operated with a system temperature rise of 70° - 100°F. Th

is furnace

is designed to be operated with a system temperature rise (ΔT) of

High Fire 35° - 65°F, Low Fire 25° - 55°F. If the furnace selected has

an identical output capacity as the original furnace, a substantial

increase in system air fl ow will be required. See

Tables 3A and B

and the airfl ow characteristics in Section 23 of this manual,

“Airfl ow.”

TABLE 3A - RANGE OF TEMPERATURE RISE

Furnace Model

Temperature Rise

60, 80, 100, 120

High Fire (HF) 35 - 65°F

Low Fire (LF) 25 - 55°F

9