4

INsTAllATION RequIReMeNTs

Introduction

Please read these instructions completely and carefully before install-

ing and operating the furnace.

MODELS HTL-D AND HTLV-D

Models HTL-D and HTLV-D are oil fired forced air up-flow furnaces

with an output capacity range of 89,000 BTU/Hr. to 140,000 BTU/

Hr.

!

CAUTION

DO NOT USE GASOLINE, CRANK CASE OIL, OR ANY

OIL CONTAINING GASOLINE.

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE OR OTHER

FLAMMABLE VAPORS AND LIQUIDS IN THE VICIN-

ITY OF THIS OR ANY OTHER APPLIANCE.

All models are CSA listed, (NRTL/C) for use with No. 1 (Stove) and

No. 2 (Furnace) Oil. Please refer to the tables on page 11 (Oil Burner

Setups) of this manual for performance and dimensional data.

In Canada, the installation of the furnace and related equipment

shall be installed in accordance with the regulations of CAN/CSA

- B139,

Installation Code for Oil-Burning Equipment

, as well as in

accordance with local codes.

In the United States of America, the installation of the furnace and

related equipment shall be installed in accordance with the regula-

tions of NFPA No. 31,

Standard for the Installation of Oil-Burning

Equipment

, as well as in accordance with local codes.

Regulations prescribed in the National Codes and Local regulations

take precedence over the general instructions provided in this instal-

lation manual. When in doubt, please consult your local authorities.

All models are shipped assembled and pre-wired. The furnace should

be carefully inspected for damage when being unpacked.

heat loss

The maximum hourly heat loss for each heated space shall be calcu-

lated in accordance with the procedures described in the manuals of

the Heating, Refrigeration and Air Conditioning Institute of Canada

(HRAI), or by other means prescribed, or approved by the local

authority having jurisdiction.

In the United States, Manual J. titled, "Load Calculation" published

by the Air Conditioning Contractors of America, describes a suitable

procedure for calculating the maximum hourly heat loss.

location of unit

The furnace should be located such that the flue connection to the

chimney is short, direct and consists of as few elbows as possible.

When possible, the unit should be centralized with respect to the

supply and return air ductwork. A central location minimizes the

trunk duct sizing. All models may be installed on combustible floors.

The minimum installation clearances are listed in

Table 1

.

location

clearance to combustibles

hTl-D and hTlV-D

up flow

Top

1"

Bottom

0* Combustible Floor

S /A Plenum

1"

Rear

1"

Sides

1"

Front

1" **

Flue Pipe

9"

Enclosure

Closet

* No carpet or vinyl

** 24 in. Required for service clearance

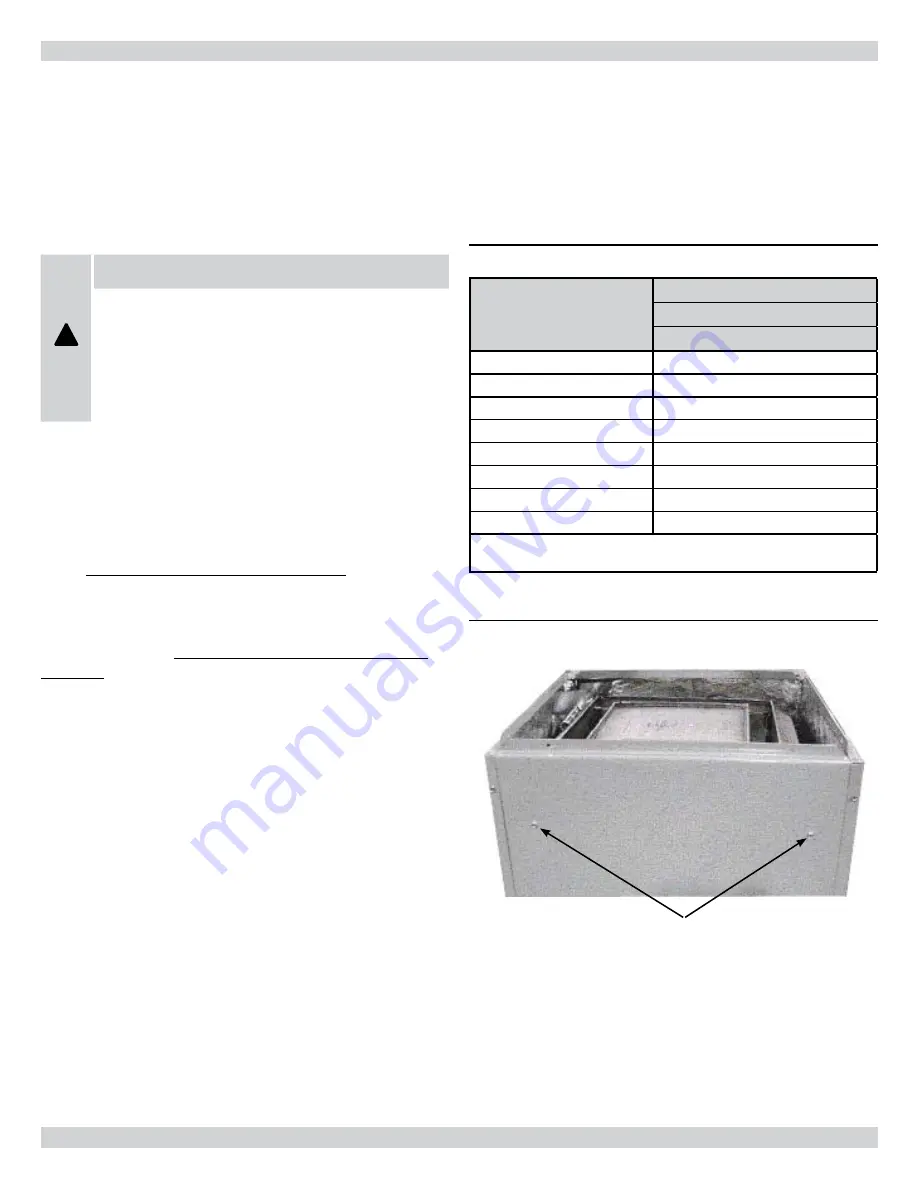

HEAT EXCHANGER SUPPORT SCREWS

Before final placement of the furnace, the heat exchanger support

screws should be removed (See

Figure 1

). This may be preferable

if the furnace rear panel will be inaccessible after installation. The

screws must be removed if the heat exchanger needs to be removed

from the cabinet.

Table 1 - clearances

figure 1 - heat exchanger support screws

Summary of Contents for HTL-100D

Page 18: ...18 Wiring Diagrams Figure 6 Chimney Vent Burner Wiring Diagram HTL D HTLV D...

Page 22: ...22 Oil Primary Control Sequence of Operation...

Page 31: ...31 Homeowner s Reference Table...

Page 33: ...33 PARTS LISTING HIGHBOY MODEL HTL D AND HTLV D Figure 9 Model HTL D and HTLV D...

Page 34: ...34 HTL D HTLV D Oil Fired Warm Air Furnace NOTES...