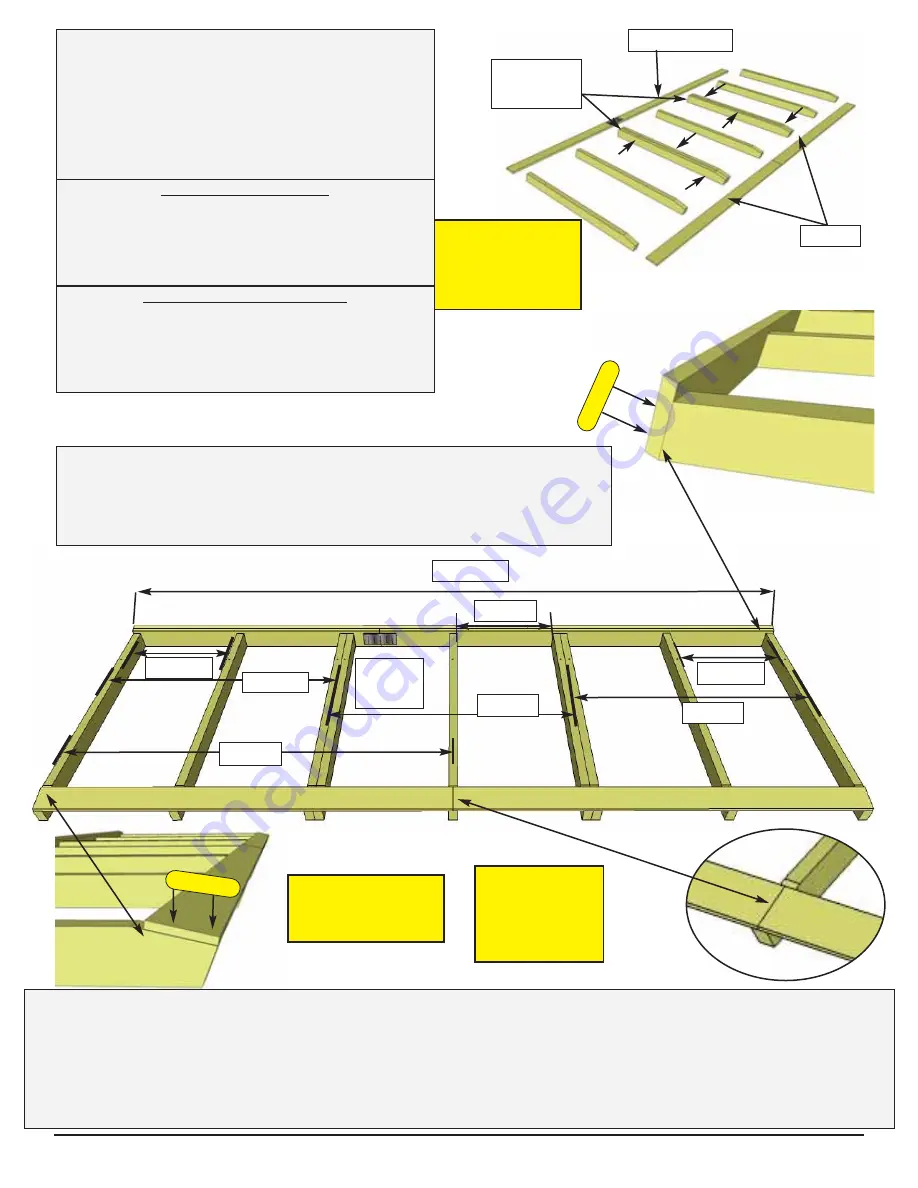

Ridge Board

Soffits

Rafter

Sof

fit

68 1/4”

45 1/2”

20 1/2”

20 1/2”

20 1/2”

45 1/2”

45 1/2”

136 1/2”

Connector

Plate to

inside

2 1/2” Screws

into Doubled

up Rafters

Carefully flip

Rafter Sections

over when

complete

Important:

Pilot Hole Ridge

Board to prevent

splitting!

Important:

Pilot Hole Soffit to

prevent splitting!

PreDrill!

PreDrill!

Parts (Steps 29 - 31)

Rafters

(1 1/2” x 3 1/2” x 56 1/2”)

x 18

Soffits

(1” x 4 1/2” x 68 1/4”)

x 4

Hardware (Steps 29 - 31)

S1

- 2 1/2” Screws

x 32 total

S3

- 2” Screws

x 16 total

29.

Locate

9 - Rafters, 2 - Soffits

& complet-

ed

Ridge Board.

Lay out on level ground as

shown to the right. Double up

Rafters

as illus-

trated. Screw doubled up

Rafters

together with

3 - 2 1/2” screws

per piece.

Note:

completed

Rafer section will be flipped over in

Step 38

.

31.

Attach end of a

Soffit

Board flush to ends of outside

Rafters

with

2 - 2 1/2” screws

per rafter end. Drill

pilot hole in

Soffit

ends to prevent splitting. Complete both outside

Rafter

&

Soffit

connections first. Measure

and position interior

Rafters

as illustrated above. When positioned correctly, attach

Soffits

to remaining

Rafters

with

2 - 2 1/2” screws

per

Rafter

. Flip completed

Rafter

section over. Complete 2nd

Rafter

section

now as per

Steps 35 - 38

with the following exception.

When attaching Ridge Board to Rafter ends, make

sure Ridge Board Connector is positioned offset to first Rafter Section. See Step 45 for illustration.

30.

Attach completed

Ridge Board

to ends of both outside rafters

with

2 - 2” screws

per end. Measure and position interior

Rafters

as

illustrated below. When positioned correctly, attach

Ridge Board

to

remaining rafters with

2 - 2” screws

per

Rafter

end.

Toll Free 1-888-658-1658 www.outdoorlivingtoday.com sales@outdoorlivingtoday.com

Page 21