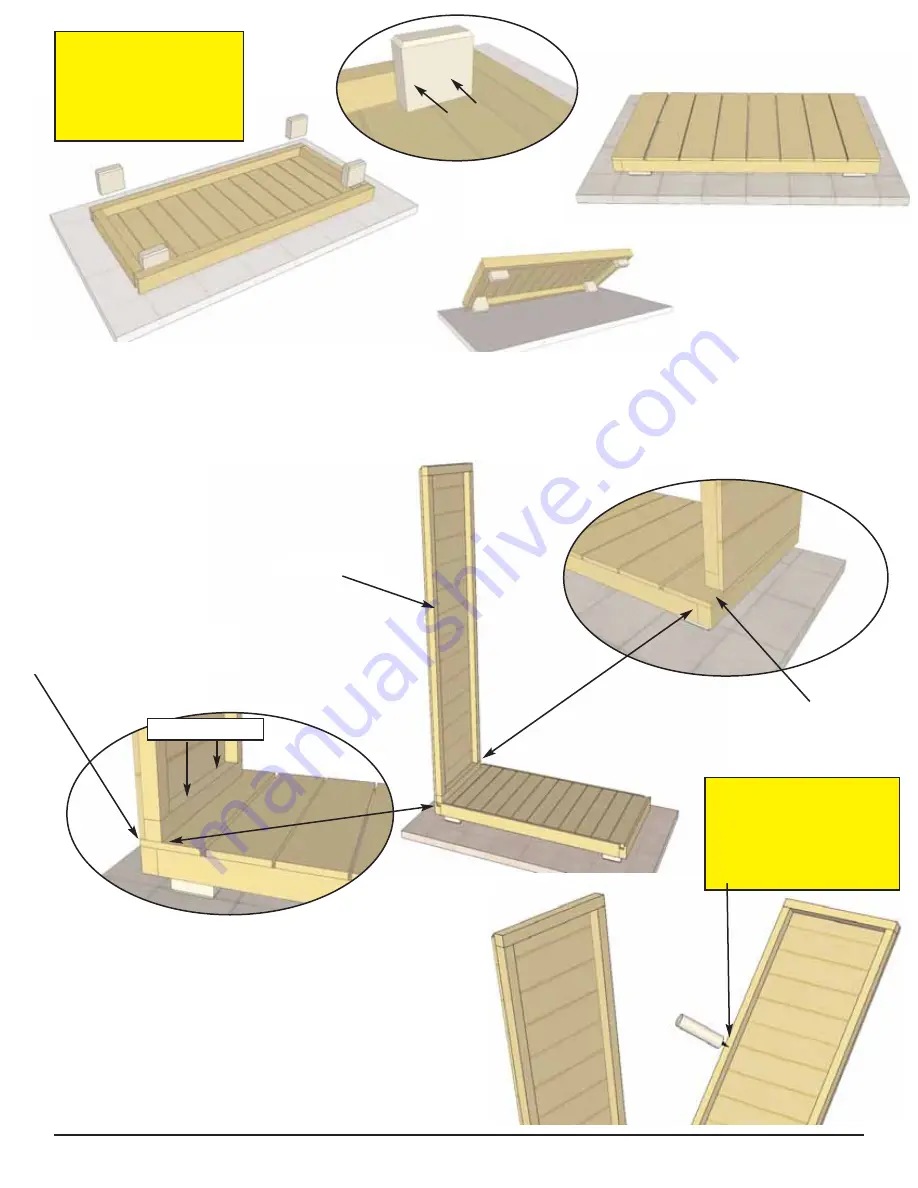

1.

Flip

Floor (A)

over on a level surface. Locate

Legs (B)

and position in each corner tight to floor and

framing and attach with 2- 2 1/2” screws. Complete all Leg att achments. Flip Floor over and complete Leg

attachments by screwing 1 - 2 1/2” screws through Floor Boards into each Leg. Level Floor before

proceeding to

Step 2

.

You can find the Square Drive Bit for the screws in with the Hardware Kit Bag.

Front

2.

Locate

Side Walls (C)

and

Rear Walls (D)

. Make sure

walls are in correct orientation (Siding cut flush with Wall

Framing at bottom). Position Side Wall on Floor so it sits

flush with front and side. Have helper hold Side W all while

Rear Wall is positioned on Floor. Screw Side Wall down

to floor with 2 - 2 1/2” screws when aligned correctly .

Optional -

Caulking wall seams will help prevent moisture

from entering at seam.

Caulking not Included in Kit.

Front

Rear

Side Wall (C)

Side Wall Flush with Floor

Frame at Front and Side

At Rear, a gap

will exist.

Caulking

Optional

- Caulking

seams will help prevent

moisture from entering

at seam.

Caulking not

included in kit.

Toll Free 1-888-658-1658 sales@out doorlivingtoday.com

Page 4

You can find the

Square Drive Bit for

the screws in with

the Hardware Kit

Bag.

2 1/2” Screws