3.

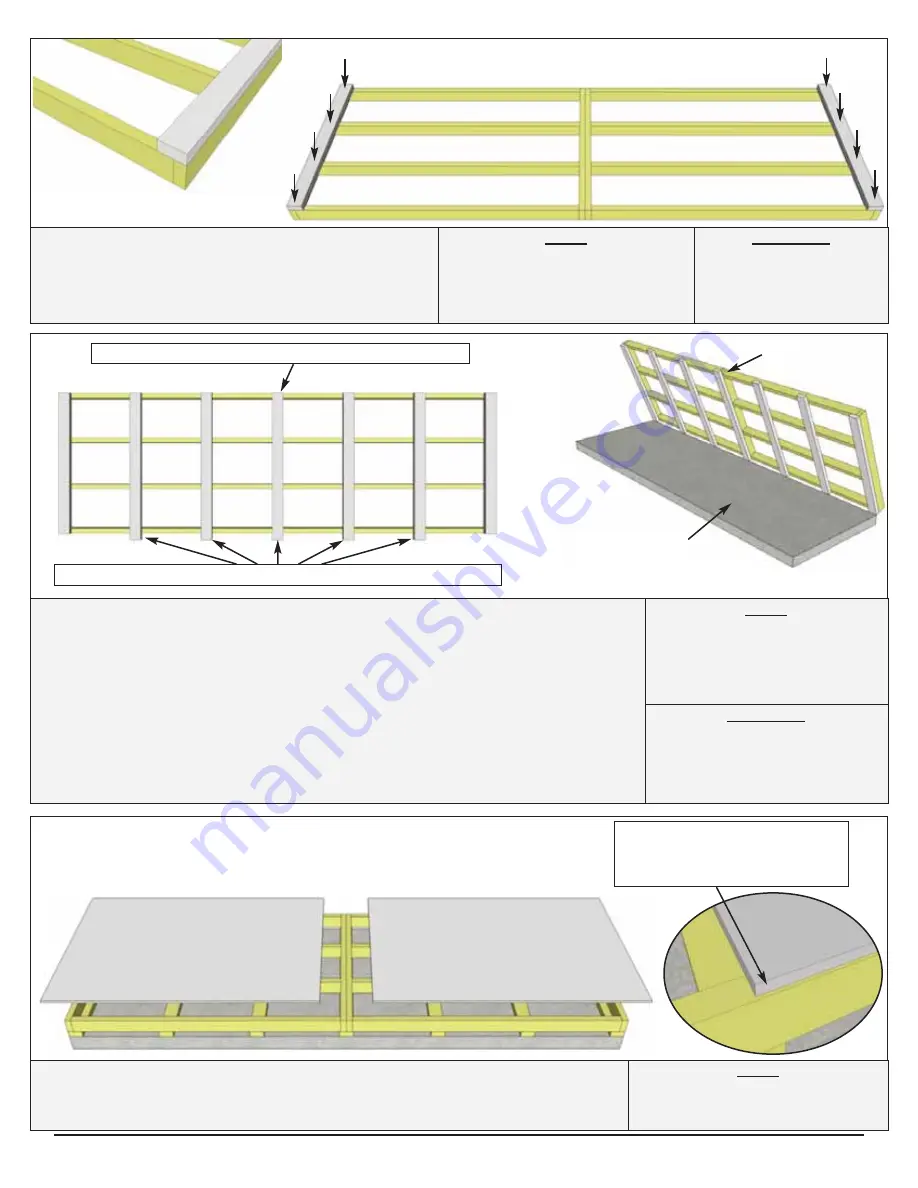

Position

1C

- Floor Runners - Short

on each

side of the completed floor frame. Runners should

be flush with corners but not overhanging. Attach

with

4 - 2 1/2”

Screws

per Runner.

Parts

1C - Floor Runners - Short

(1 1/2” x 3 1/2” x 45 1/2”)

x 2

Hardware

S1

- 2 1/2” Screws

x 8 total

4.

Align

1CC - Floor Runners - Long

evenly spaced as shown above and

flush with the back of the Floor Frame. On the front, Runners will extend 2”

past the Floor Frame to provide support for the Sliding Door Track later in

the Assembly. Attach with

4 - 2 1/2”

Screws

per Runner.

With Floor Runners attached, carefully flip the floor over and place on your

foundation.

Caution -

Be careful when laying floor down not to bend or twist

floor.

Note:

Having a level foundation is critical. Choosing a foundation will

vary between regions. Typical foundations can be concrete pads or patio

stones positioned underneath the floor runners.

5.

Position

1D - Plywood Floor

on top of completed floor frames.

Plywood will sit slightly inset from outside of floor frame.

Parts

1D -

Plywood Floor

(5/8” x 45 3/8” x 70 5/8”)

x 2

Note:

Plywood is cut slightly

smaller than floor framing.

Keep plywood seams tight.

Parts

1CC - Floor Runners - Long

(1 1/2” x 3 1/2” x 47 1/2”)

x 5

Hardware

S1

- 2 1/2” Screws

x 20 total

Long Floor Runners overhanging Floor Frame on front.

Floor Runners flush with Floor Frame on back.

Concrete Slab

Foundation

Front

Toll Free 1-888-658-1658 www.outdoorlivingtoday.com sales@outdoorlivingtoday.com

Page 9