27

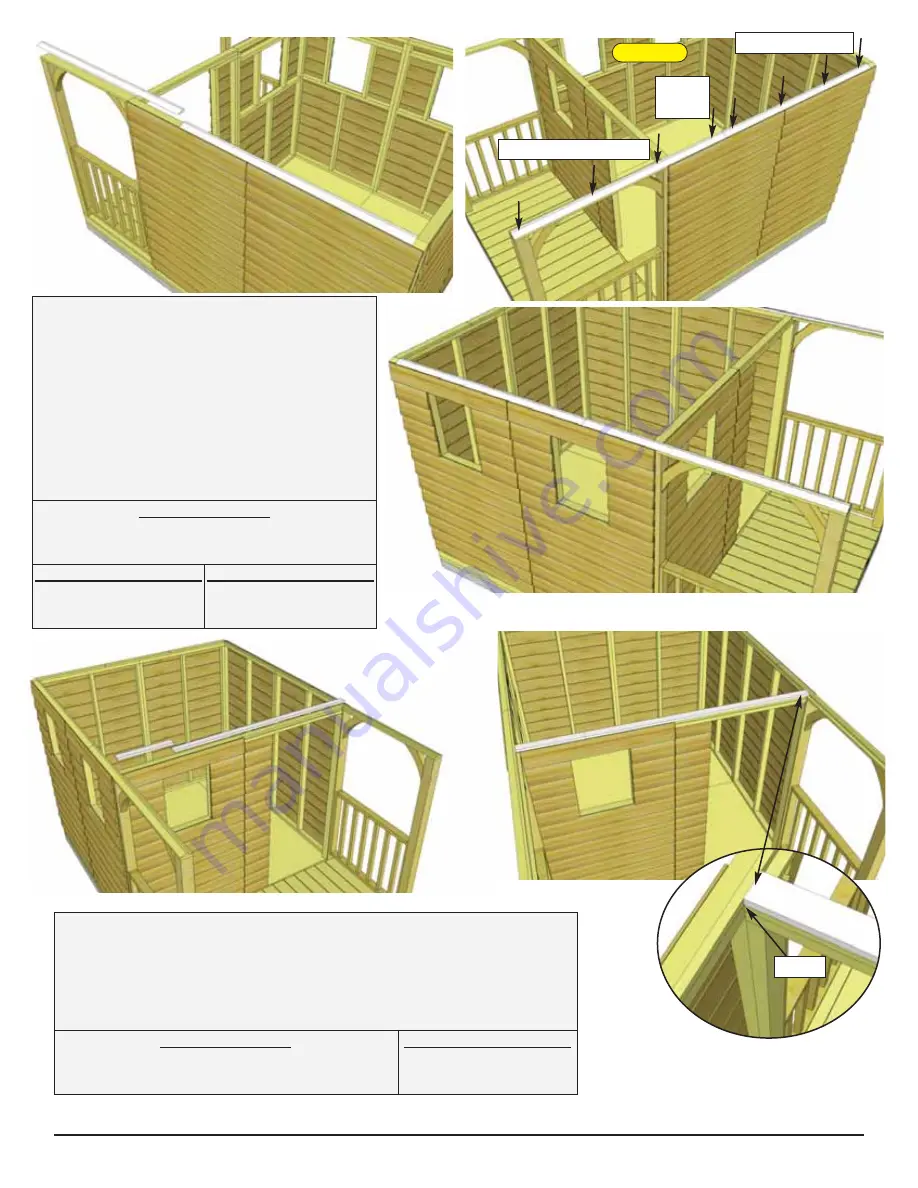

. Position the

Front Top Plates

on top of Door Header and

front wall panel. There are 2 plates (72” and 19” long). Front top

plates are straight cut on the ends. Once again, the plate will be

flush with inside of top wall framing. Attach with

6 - 2” screws

(4 screws in long and 2 in short plate).

26.

Attach the 4

Side Top Plates

. The

side top plates are angle cut down the

length. Once again, position top plate on

wall plate so it is flush with inside of wall

plate. Side plate should also be flush with

rear wall plate. Secure with:

4 - 2” screws per rear piece.

1 - 2” screw & 3 - 1 1/4” screws

per

front piece.

PreDrill!

4 - 2” Screws

1 - 2”

Screw

3 - 1 1/4” Screws

Flush

Parts (Steps 26)

Side Top Plates

(3/4” x 2 1/2” x 67”)

x 4

Hardware (Steps 26)

S3

- 2” Screws

x 10 total

Hardware (Steps 26)

S2

- 1 1/4” Screws

x 6 total

Parts (Steps 27)

Front Top Plates

(3/4” x 2 1/2” x 72” & 19”)

x 2

Hardware (Steps 27)

S3

- 2” Screws

x 6 total

Toll Free 1-888-658-1658 www.outdoorlivingtoday.com sales@outdoorlivingtoday.com

Page 21