We hope your experience assembling your Sunshed has been both positive and rewarding.

We value your feedback and would like to hear back from you on how well we are doing in the

following areas:

1. Customer Service

2. On Time Shipping

3. Motor Freight Delivery

4. Quality of Materials

5. Assembly Manual

6. Overall Satisfaction.

Please call, write or email us at:

Toll Line: 1.888.658.1658 | Fax: 1.604.462.5333 | sales@outdoorlivingtoday.com

Canadian Address

9393 287th Street

Maple Ridge, British Columbia

Canada V2W 1L1

United States Address

P.O. Box 96

Sumas, Washington

USA 98295

Outdoor Living Today

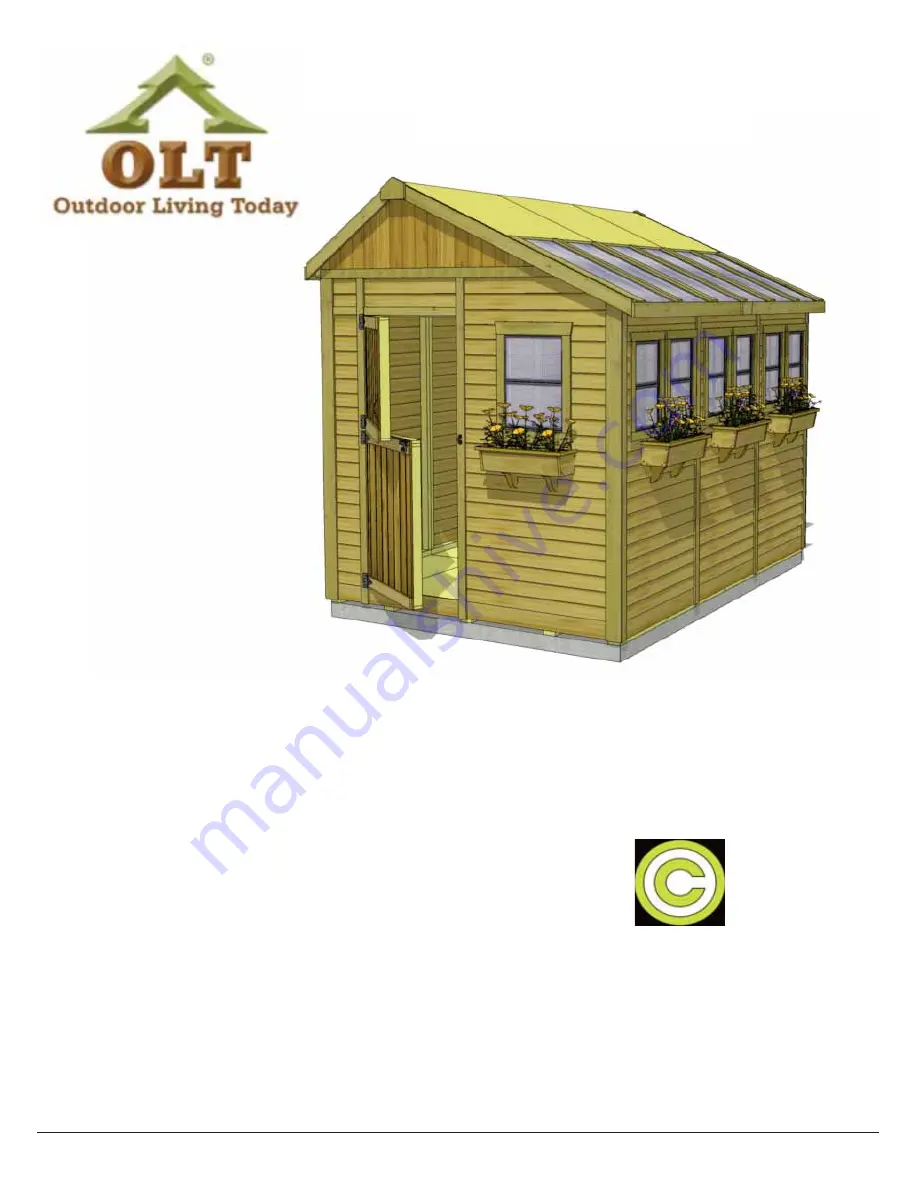

Congratulations on Completing

your 8 x 12 Sunshed!

Note:

Our buildings are

shipped as an unfinished

product. If exposed to the

elements, the western red

cedar lumber will weather to

a silvery-gray color. If you

prefer to keep the cedar

lumber looking closer to the

original color, we suggest

that you treat the wood with

a good oil base wood stain.

You may also wish to paint

your new shed rather than

stain it. In both cases we

recommend that you

consult with a paint and

stain dealer in your area for

their recommendations.

The materials contained in this Assembly

Manual may be downloaded or copied

provided that

ALL

copies retain the copyright

and any other proprietary notices contained

on the materials. No material may be

modified, edited or taken out of context such

that its use creates a false or misleading

statement or impression as to the positions,

statements or actions.

Page 38