14

RECOMMENdEd MAINTENANCE PROCEdURES

ROUTINE INSPECTION

It is recommended that you periodically inspect your

DELTA

®

Dual Drum Sander as a precautionary action.

During this time, check all hardware such as bolts,

nuts and screws to ensure they are properly tightened.

Also verify that the sanding belts and drive belts are

mounted properly and have not become loose or torn.

Also take this opportunity to inspect for dust and/or

wood particles that may have accumulated on or in the

machine.

LUBRICATION

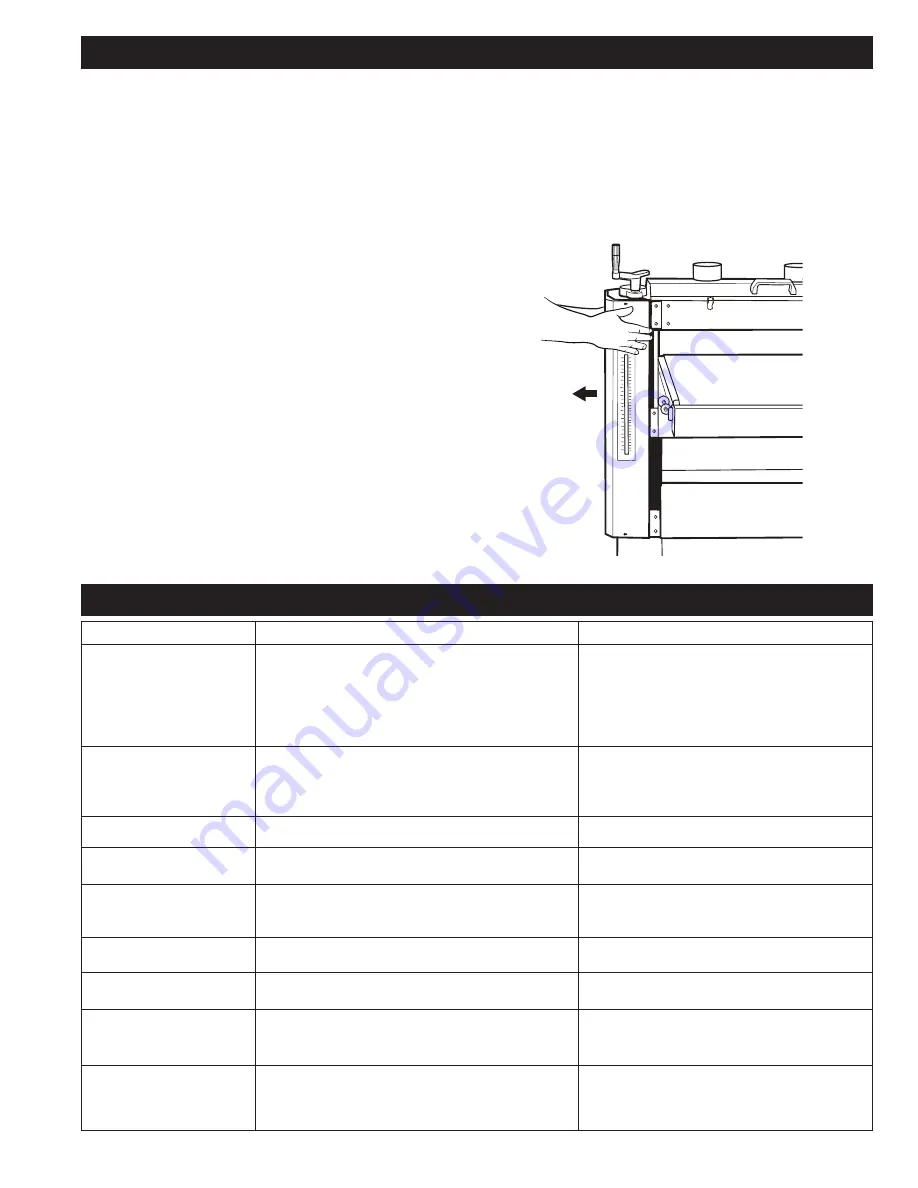

The table height adjustment screw shafts, located at

either end of the machine must be well lubricated with

grease at all times. In order to access, inspect and

lubricate the screw shafts, it is necessary to remove

the two side guards located on either end of the

machine.

To remove the side guards:

1. Remove the elevation cursor by unscrewing the

retaining screw.

2. Remove the eight Phillips head bolts and washers

securing the left and right side guards to the

machine and remove the guards. See Fig. 14.

3. Re-attach side guards and elevation cursor.

CLEANINg ThE SANdINg BELTS

Regularly clean the sanding belts on the drums with

commercially available cleaning sticks, following the

manufacturer’s directions. When cleaning, also brush

the stick crumbs from the sanding drum while it is still

rotating.

FIg. 14

TROUBLEShOOTINg gUIdE

PROBLEM

POTENTIAL CAUSE

SOLUTION

Sanding surface clogs too

quickly.

Sanding grit too fine.

Too much material being removed at once.

Dirty board surface.

Insufficient dust collection.

Board contains too much moisture.

Worn sanding belt.

Change to a coarser grit.

Adjust table height.

Ensure board is free of debris prior to sanding.

Inspect dust collection system.

Properly dry stock before sanding.

Replace sanding belt (Page 8)

Sanding belt tears.

Drums not parallel to feed table.

Sandpaper edges overlapped.

Tape is slipping.

Too much material is removed at once.

Re-align drums (Page 10)

Re-install sanding belt.

Rewind the loose belt on the drum.

Lower the table height.

Rounding on the edges.

Too much material is removed at once.

Lower the table height.

Uneven thickness on right

and left side of the board.

Drums are not parallel to feed table.

Uneven wear of sanding paper.

Re-align drums (Page 10)

Replace sanding belt.

Stock slips on the feed

belt.

Too much material is removed at once.

Too much dust on the feed belt surface.

Worn feed belt.

Lower the table height.

Clean surface with air hose.

Replace feed belt (Page 8)

Shiny spots on sanded

surface.

Sanding paper too old.

Drums too high.

Replace sanding belt (Page 8)

Lower table height.

Marks on sanded surface

Partial damage to sanding paper.

Paper overlapped on edges.

Replace sanding belt (Page 8)

Re-align sanding belt on drum

Feed belt does not

run smoothly or stops

completely.

Feed belt tension is incorrect.

Belt tracking is incorrect.

Adjust feed belt tension (Page 8)

Adjust feed tracking (Page 8)

Consistently noticeable

“snipe”

No out-feed support.

Pressure roller spring tension incorrect.

Drum height incorrect in relation to pressure rollers.

Use supplementary support in rear of

machine.

Check and adjust.

Adjust pressure rollers (Page 11)