Page 11

Flexible shaft auto scaling

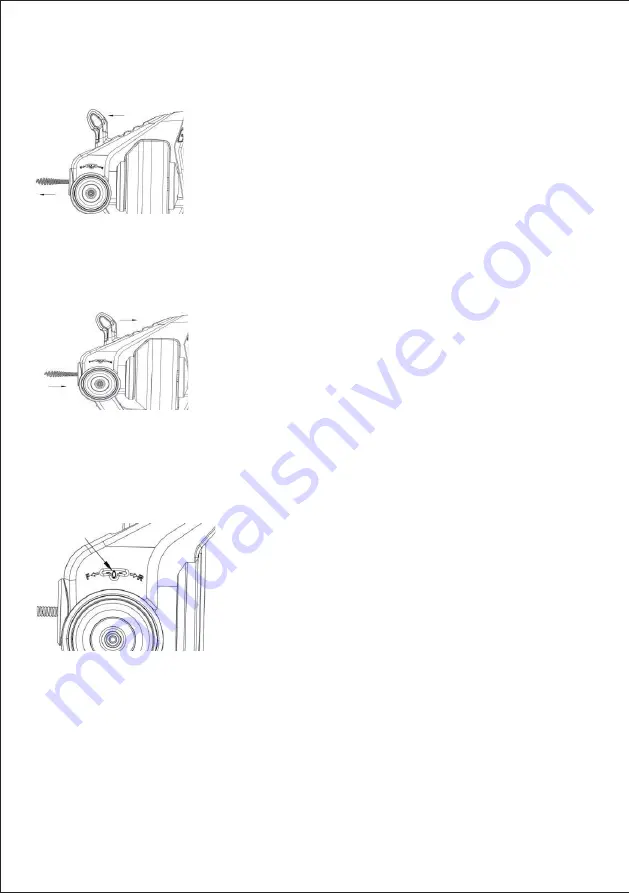

1. Press the forward and reverse rotation button L: 1) Press the speed

switch lightly, move the handle forward to the F position, and the flexible shaft

will be delivered forward (Fig. 5);

(Fig.5)

2) Press the speed switch lightly, pull the handle back to the R position, and

the flexible shaft will retract backwards (Fig. 6).

(Fig.6)

1.

When the forward and reverse rotation button R is pressed, the

flexible shaft stretches in the opposite direction.

When the operating handle is in the O neutral position, the flexible shaft stops

stretching no matter in forward or reverse rotation Fig.7

.

(Fig.7)

Pipe dredge (before operation, be familiar with the automatic scaling

operation of the flexible shaft, otherwise it will lead to personal injury or

damage to the tool)

1. Please place the tool head at a distance of less than 150mm away from

the pipe opening. If the distance is too long, it will cause the flexible shaft

to be twisted and knotted; and do not place the tool head too close to the