Page 2-5

OLYMPIC AUTO-LENGTH

™

Operation

Display

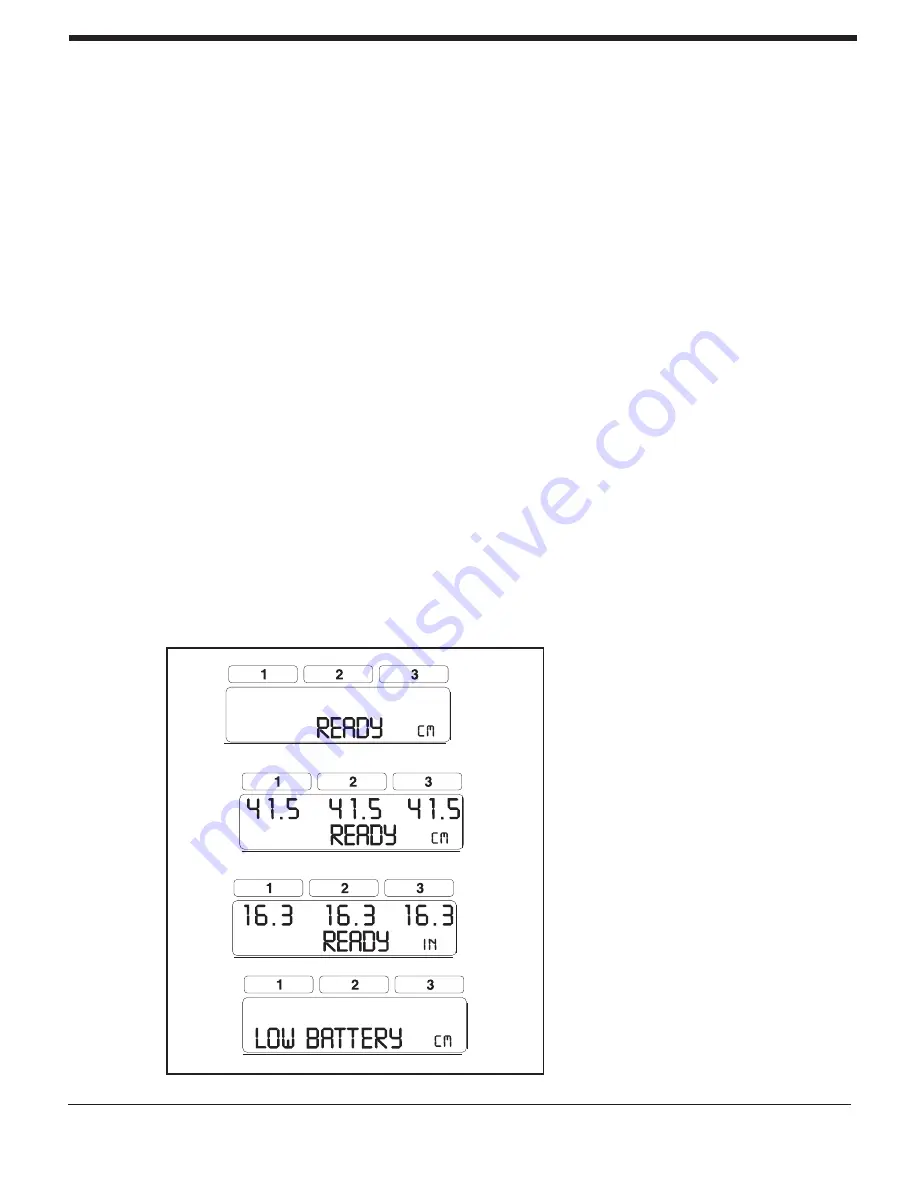

The Auto-Length’s display provides three measurement readings in

the upper half of the display screen (

Fig. 2H

). Messages appearing

in the lower half of the display screen show the Auto-Length’s status,

and prompt the operator. Common prompts include:

READY:

Indicates that power is on and the Auto-Length is ready

to measure.

RECALL:

Appears below the last measurements recalled from

memory.

CALIB:

Indicates that the Auto-Length is in its calibration mode.

LOW BATTERY:

Indicates the Auto-Length’s batteries are de-

pleted and should be recharged (see

also

Replacing the Battery

Pack

on page 3-1). Measurements cannot be made while the

“Low Battery” message appears.

ERROR:

Appears when the measuring bar jams against an

immovable obstacle and the motor stalls.

BAR JAMMED:

Appears if the measuring bar is pushed past

the rest position.

RECALIBRATE:

Appears in the upper half of the display if the

device requires calibration. “RECALIBRATE” shows until the

Auto-Length is placed into calibration mode, and the device will

not measure until it has been calibrated (see

Calibration

on

page 1-8).

Fig. 2H