CH10/CH20

C. DISASSEMBLY AND ASSEMBLY PROCEDURES

C-9

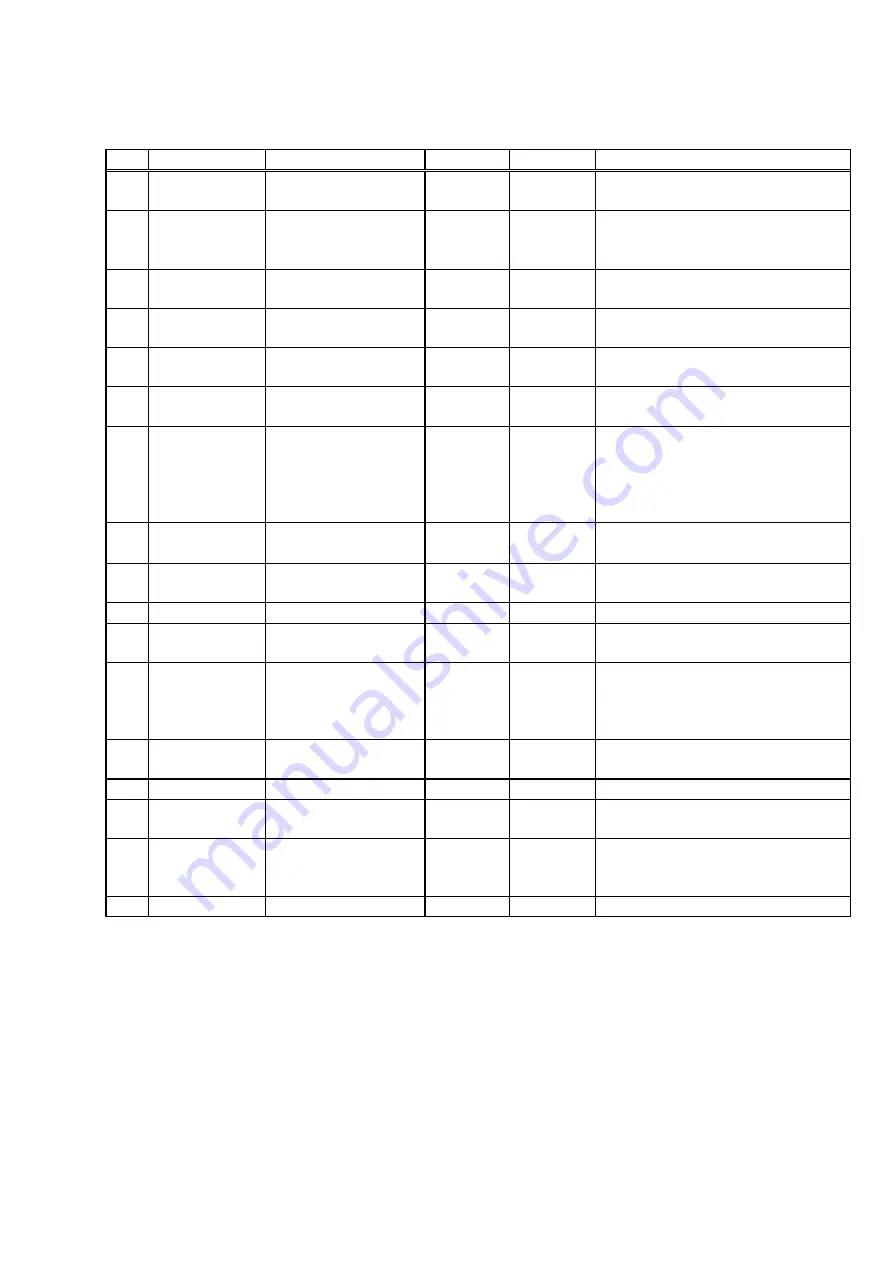

No.

Parts name

Screw

Grease

Adhesive

Remarks

•

BODY

AB3X8SA (*1)

2 pcs.

OT1028

Apply adhesive on the assembly

surface for lateral guide-1

ˆ

.

‚

CLIP HOLDER

3PUK2X8SA (*2)

3 pcs.

OT1131

Apply adhesive on the screw head.

Clearance between the stage and the

clip holder: 0.2 - 0.7 mm

ƒ

SPACER

Mount the spacer with the round edge

side faced downwards.

„

CLIP

CSK3X8SA (*3)

OT2008

Apply grease on the contact surface

with the clip holder

‚

.

…

NUT

OT2008

Apply grease on the contact surface

with the clip holder

‚

.

†

SPRING

OT2008

Clip working force: 1.0 - 1.5N {100 -

150 g}

‡

LATERAL

GUIDE-3

3PUK2. 6X10SA (*4)

3 pcs.

SP1.6X4UO (*5)

PSTB1. 7X3SA (*6) 2

pcs.

OT1131

Apply adhesive on the screw head.

ˆ

LATERAL

GUIDE-1

PSTB1. 7X3SA (*7) 2

pcs.

OT2008

Apply grease on the fitting surface of

wire guide

±

15

thinly.

‰

WIRE GUIDE

(2 pcs.)

OT2008

±

10

CASING

B3SO (*9) 6 pcs.

OT2008

Apply grease on the balls.

±

11

WIRE GUIDE

(2 pcs.)

OT2008

±

12

LATERAL

GUIDE-2

PSTB1. 7X3SA (*8) 4

pcs.

Apply grease on the wire guide fitting

surface thinly.

Rotation force at assembling the X/Y-

knob: 0.2 - 0.98N {20 - 100 g}

±

13

WIRE GUIDE

(2 pcs.)

OT2008

±

14

CASING

B3SO (*10) 6 pcs.

OT2008

Apply grease on the balls.

±

15

WIRE GUIDE

(2 pcs.)

OT2008

±

16

X-RACK

3PUK2X6SA (*11)

2 pcs.

HWB2SA (*12) 2 pcs.

OT1131

Apply adhesive on the screw head.

±

17

SPRING