Chapter 3 Cleaning, Disinfection and Sterilization Procedures

37

EVIS LUCERA JF/TJF TYPE 260V REPROCESSING MANUAL

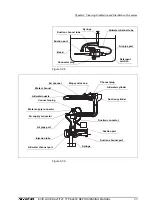

Brushing the channels

• Be sure to brush the inside of the suction channel.

Otherwise, insufficient cleaning and/or disinfection of the

endoscope may pose an infection control risk to the patient

and/or operators performing the next procedure with the

endoscope.

• To avoid splattering detergent solution when the channel

cleaning brush is pulled out, keep the endoscope

submerged.

• The channel cleaning brush is a consumable item. Repeated

use may cause the brush head to become bent or kinked,

which could cause it to come off during use. Confirm that the

brush is free from any damage or other irregularities before

and after each use. Should a part of the brush come off

inside the endoscope, immediately retrieve it and carefully

confirm that no parts remain inside the channel of the

endoscope by passing a new cleaning brush or other

endo-therapy accessory through the channel. Any parts left

in the channel can drop into the patient during the procedure.

Depending on the location, the missing part may not be

recoverable by passing a new brush or other endo-therapy

accessory through the channel. In this case, contact

Olympus.

• Withdraw the channel cleaning brush from the suction

channel gently, ensuring that its shaft does not rub against

the external opening of the suction cylinder. This could

damage the brush and/or may wear a groove in the opening,

leading to impaired suction and liquid leakage.

• Do not attempt to pass the channel cleaning brush from the

distal end of the insertion tube and/or suction connector. It

may get caught, making retrieval impossible.