Summary of Contents for Omk.SZP01.E11.0101.Z5F

Page 2: ......

Page 12: ...10 G DEMONTE G R N ve YEDEK PAR A 8 L TRE...

Page 16: ...14 G DEMONTE G R N ve YEDEK PAR A 10 L TRE...

Page 20: ...18 G DEMONTE G R N ve YEDEK PAR A 13 L TRE...

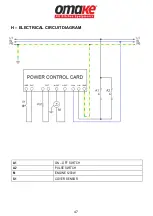

Page 25: ...23 H ELEKTR K EMASI A1 A KAPAT ANAHTAR A2 PULSE ANAHTAR M MOTOR 1200W S1 KAPAK SENS R...

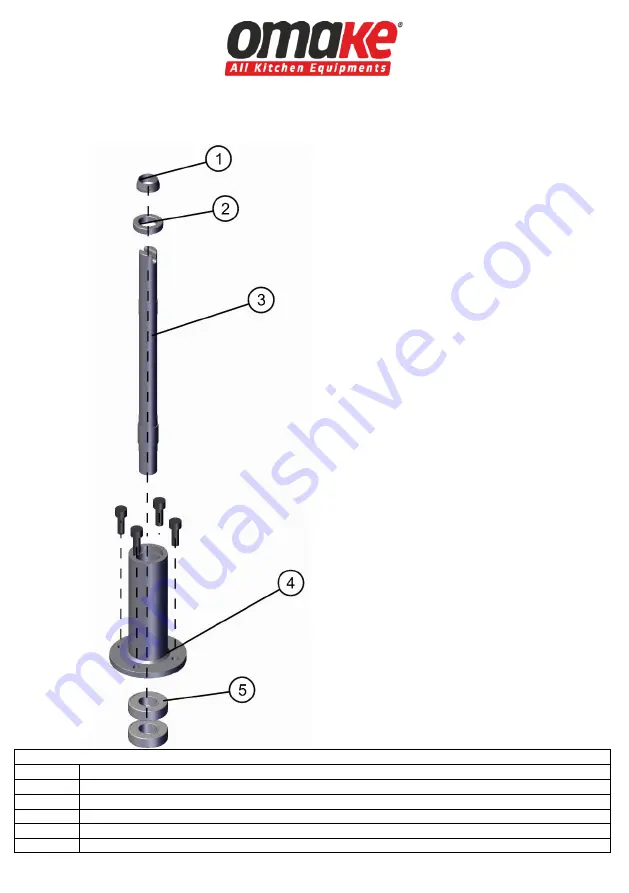

Page 36: ...34 G EXPLODING DRAWING AND SPARE PART LIST 8 LITER...

Page 40: ...38 G EXPLODING DRAWING AND SPARE PART LIST 10 LITER...

Page 44: ...42 G EXPLODING DRAWING AND SPARE PART LIST 13 LITER...