D877 MGB Rev01 HE250.docx

39/50

6 Automatic reduction of travel times

Reduce travel times it allows to increase performance of 'elevator and upward, in the presence of a constant

speed motor-pump, reduce consumption and oil heating.

In the valve group Hevos HE250 the reduction of travel times is realized in two modes:

-

automatic reduction of upward and downward leveling space, expressed as the traveled at low speed

before stopping.

-

reduction of the time of starting and maximum obtainable upward speed

6.1

Recovery leveling space

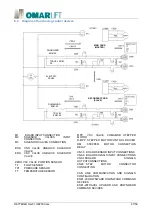

The automatic recovery of leveling spaces is activated by setting the Par. 456 = 1.

So, the first up and down stroke, the system calculates the value of the leveling space, and if space is different

from the minimum provided by Par. 458 for upstroke, and Par. 459 for downstroke, implements a deceleration

space correction to reflect the value provided in the parameter.

The self-learning system is reset every time is turned off the control board or the operating parameters are

modified (speed or space).

(u2-u6,d2-d6,u3,d3,u4,d4,u5,d5,r1-r2) Display on DSP during phase execution

6.2

Reduction of starting time and maximum upward speed

The reduction of the total upstroke time reduces the consumption and oil heating.

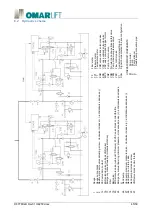

The synchronization between the output contact AVV and digital input SFY electronic card, allows you to start

the engine when the VSC valve, which controls the discharge of the oil coming from the pump is open and

begin to close the VSC soon as the engine is started, reducing to a minimum the engine operation during the

"dead" times, this also occurs during stoppage of the engine in the soft-stop.

Once started the engine, to optimize the starting time of equipment, the system prepares the closing of the

valve to the mapped VSC position, depending on the pressure in the circuit and of the value of the nominal

flow of the pump (Par. 102) and from that moment start the taking charge of the cabin.

When a minimum flow to piston is detected, the system enters a control to implement the acceleration

prescribed in the corresponding parameters.

However, setting a short acceleration space, it allows to reduce the acceleration time and therefore the

dissipation during this phase.

Based on the pressure and the operating temperature, the flow rate of the pump can have variations of +/-

10%.

1.A Normal stroke with "short" deceleration

1.B Deceleration delay r1 o r2

2.A Normal stroke with "long" deceleration

2.B Deceleration correction