42/50

D877 MGB Rev01 HE250.docx

9. The double pressure test allows you to check the integrity of all the entities under normal pressure.Use

the hand pump valve group to reach a value gradually double pressure than the static maximum

expected in the system.

10. Check that the oil level with the cabin top floor, is in the tank, above the minimum mark on the dipstick.

Make sure the color of the oil is not changed and that it does not present a strange smell.

11. If present, disconnect one of the ends of the motor protection series and verify that the motor protection

device is intervened.

12. Check the status of the solenoid valves and filters the tap to the drawing 1.

13. Check the hose not leaking or deformation on the outside and on the fittings and it is visible the test

marking (manufacturer, date and test pressure).

14. If not specified by the manufacturer of the hose, necessary to replace, within a period of 10 years from

its installation.

15. The revision of the valve unit provides for the replacement of the seals on the valves and filters. After

a review performed all the inizials tests.

16. Verify that the group's identification number plate is in the correct position and legible.

Also check the instructions of the emergency maneuvers, the oil plate, the wiring diagrams of the

picture and the hydraulic diagram of the control unit.

7.3

Filters and solenoid valve

Attention all filters are normally pressurized!

The valve group HEVOS HE250 can work setting P231 = 2 parameter in combination with an auxiliary micro-

levling group that works in upward travel to recover the right flor level to without the mail motor.

In this conditin the valve group remains passive and the flow coming from the pump is directed to the piston

for all the time.

In respect with the normal operation, the differences are exclusively related to the micro-leveling upward phase

and are:

1. With the upward travel activate the only UP input and power the micro-leveling

2. The relief valve test command is not executed

3. During the ascent the PNP1 monitoring signal is not managed and remains at level 0

4. The AVV output contact (motor-pump management) is not activated

5. During upward travel the micro-leveling the ERS input solenoid valve must not be supplied

6.

During upward operation on the Display of the SCH001 card the indication "AL" appears

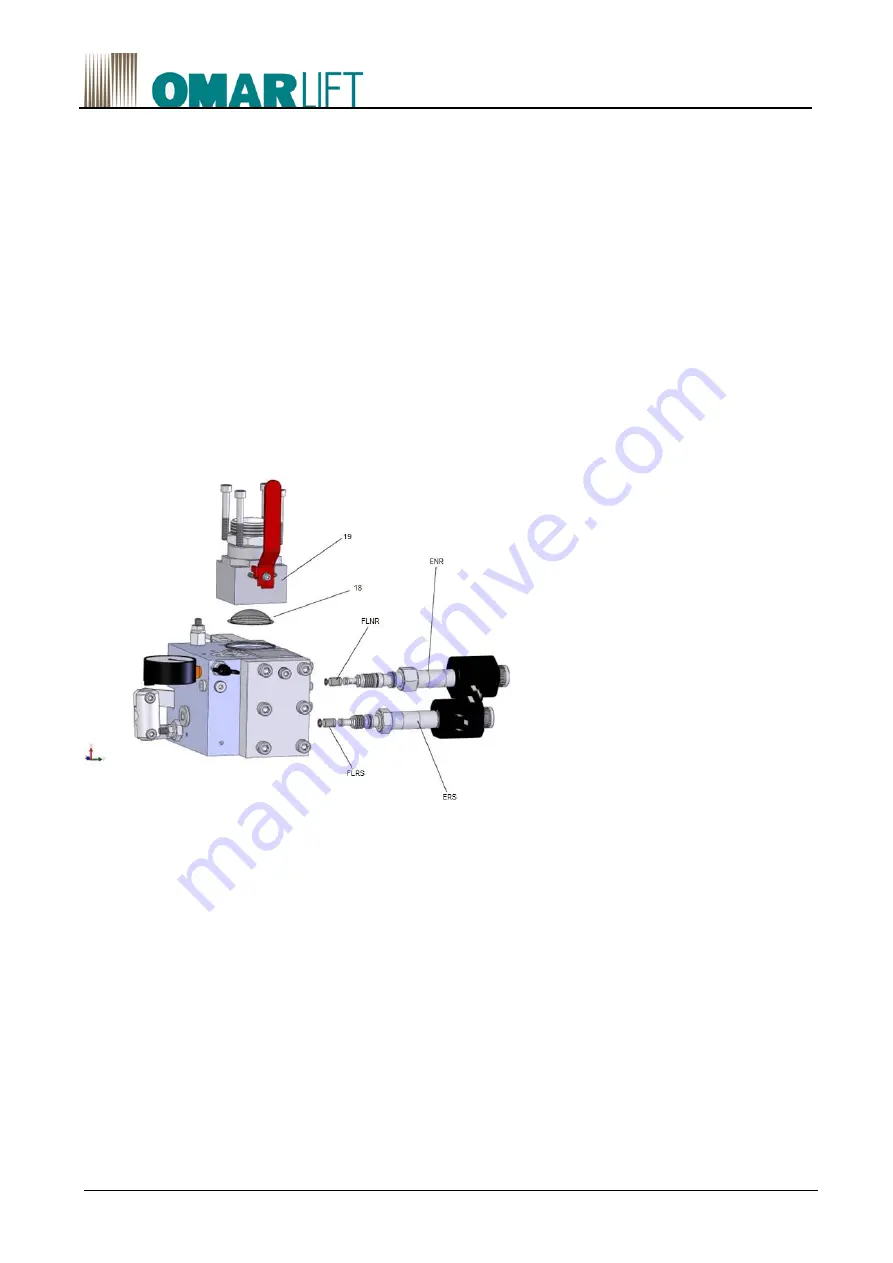

18 - Flow Filter - code DSG02316200

19 - Exclusion tap valve group

FLNR - Solenoid valve filter ENR - code DSG09903201

FLRS - Solenoid valve filter ERS - code DSG09903201