OMAX JetMachining® Center Operator’s Guide

x

400433D-EN

Figure 4-3: Removing the Nozzle Mixing Tube .............................................................................................. 4-6

Figure 4-4: Removing the Nozzle Body from the Inlet Body.......................................................................... 4-7

Figure 4-5: Screwing the Removal Tool into the Filter Seal ........................................................................... 4-7

Figure 4-6: Removing the Orifice Assembly from the Nozzle Body .............................................................. 4-7

Figure 4-7: Removed Orifice Assembly and Mixing Chamber Disc............................................................... 4-8

Figure 4-8: Pressing the Mixing Chamber from the Nozzle Body .................................................................. 4-8

Figure 4-9: Removing the O-ring from the Nozzle Body ................................................................................ 4-9

Figure 4-10: Rinsing Parts with Clean Water .................................................................................................. 4-9

Figure 4-11: Cleaning Parts in Ultrasonic Cleaner with White Vinegar........................................................ 4-10

Figure 4-12: The Four Primary Nozzle Assembly Components Requiring Inspection ................................. 4-10

Figure 4-13: Good Jewel Orifice.................................................................................................................... 4-10

Figure 4-14: Chipped Orifice Assembly Jewel .............................................................................................. 4-11

Figure 4-15: Plugged Jewel Orifice ............................................................................................................... 4-11

Figure 4-16: Worn Mixing Chamber Discs.................................................................................................... 4-12

Figure 4-17: Worn Mixing Tubes .................................................................................................................. 4-12

Figure 4-18: Pump and Nozzle Test Options ................................................................................................. 4-13

Figure 4-19: Installing the Mixing Tube Upside Down to Dislodge a Clogged Opening ............................. 4-13

Figure 4-20: Worn Mixing Chamber ............................................................................................................. 4-14

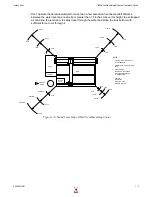

Figure 4-21: Purging the High-pressure System of Contaminates with the Nozzle Removed ...................... 4-14

Figure 4-22: Nozzle Filter Seal Assembly ..................................................................................................... 4-14

Figure 4-23: Filter Seal Assembly Inserted into Inlet Body .......................................................................... 4-15

Figure 4-24: Locating the Mixing Chamber Groove and Abrasive Inlet Hole for Alignment ...................... 4-15

Figure 4-25: Using the Push Tool and Arbor Press to Insert the Mixing Chamber into the Nozzle Body.... 4-15

Figure 4-26: Installing the O-ring on the Nozzle Body ................................................................................. 4-16

Figure 4-27: Placing the Mixing Chamber Disc in the Center Bore of the Nozzle Body.............................. 4-16

Figure 4-28: Inserting the Orifice Assembly in the Nozzle Body with the Jewel Side Facing Up................ 4-16

Figure 4-29: Applying Blue Goop to the Nozzle Body Inlet Threads ........................................................... 4-17

Figure 4-30: Installing the Nozzle Body onto the Nozzle Inlet Body............................................................ 4-17

Figure 4-31: Aligning the Nozzle’s Abrasive Inlet Hole ............................................................................... 4-17

Figure 4-32: Damage Caused by an Off-center Orifice ................................................................................. 4-18

Figure 4-33: Tightening the Nozzle’s Brass Retainer Nut ............................................................................. 4-18

Figure 4-34: Tightening the Nozzle Body to the Inlet Body.......................................................................... 4-18

Figure 4-35: Inserting the Mixing Tube into the Nozzle Body...................................................................... 4-19

Figure 4-36: Placing the Mixing Tube Collet and Nut onto the Mixing Tube............................................... 4-19

Figure 4-37: Tightening the Mixing Tube onto the Nozzle Body.................................................................. 4-19

Figure 4-38: Abrasive Damage from Not Using a Nozzle Muff.................................................................... 4-21

Figure 4-39: Removing the Air Hose from the Air Canister Fitting Ring ..................................................... 4-22

Figure 4-40: Using a 1-1/8" open-end Wrench to Remove the Air Canister ................................................. 4-22

Figure 4-41: Removing the Coil Nipple From the On/Off Valve Body Adapter Fitting............................... 4-22

Figure 4-42: Removing the 5mm Allen Screws that Secure the On/Off Valve Body ................................... 4-23

Figure 4-43: Removing the On/Off Valve Body with Seat from the Tilting Plate ........................................ 4-23

Figure 4-44: Removing the Inlet Body from the Tilting Plate ....................................................................... 4-23

Figure 4-45: Installing the Body Removal Tool Post to Remove a Stuck Inlet Body ................................... 4-24

Figure 4-46: Placing the Tube over the Tool Post and Tightening the Flange Nut ....................................... 4-24

Figure 4-47: Removing the Brass Inlet Body Retaining Nut with the Spanner Wrench ............................... 4-24

Figure 4-48: Using White Vinegar to Loosen a Stuck Inlet Body ................................................................. 4-25

Figure 4-49: Tightening Flange Nut to Detach the Inlet Body ...................................................................... 4-25

Figure 4-50: Cleaning the Inlet Body Hole with Brush and Soapy Water..................................................... 4-25

Figure 4-51: Applying Blue Goop to the Inlet Body Male Threads and Bore Diameter ............................... 4-26

Figure 4-52: Hand Tightening the Inlet Body and Aligning to Tilting Plate Hole ........................................ 4-26

Figure 4-53: Applying Blue Goop and Anti-seize Compounds to Valve Body Components ....................... 4-26

Figure 4-54: Correct Placement of the Valve Body Seat into the Valve Body.............................................. 4-27

Figure 4-55: Placing the On/Off Valve Body Against the Cutting Head Inlet Body..................................... 4-27

Figure 4-56: Tightening the Four Valve Body Screws and Applying Blue Goop to the Gland Nut Threads 4-27

Figure 4-57: Tightening the Coil Nipple to the On/Off Valve Body Adapter Fitting ................................... 4-28

Figure 4-58: Installing the On/Off Valve Air Canister .................................................................................. 4-28

Figure 4-59: Removing the MiniJet Nozzle Body from the Inlet Body Extension........................................ 4-29

Figure 4-60: Removing the Inlet Body Extension from the Inlet Body......................................................... 4-29

Summary of Contents for JetMachining Center 2626

Page 8: ...OMAX JetMachining Center Operator s Guide viii 400433D EN ...

Page 12: ...OMAX JetMachining Center Operator s Guide xii 400433D EN ...

Page 22: ...OMAX JetMachining Center Operator s Guide Safety First 1 10 400433D EN ...

Page 140: ...OMAX JetMachining Center Operator s Guide OMAX Glossary 6 16 400433D EN ...

Page 144: ...OMAX JetMachining Center Operator s Guide Index 4 400433D EN ...