Maintenance

OMAX JetMachining® Center Operator’s Guide

400433D-EN

4 - 51

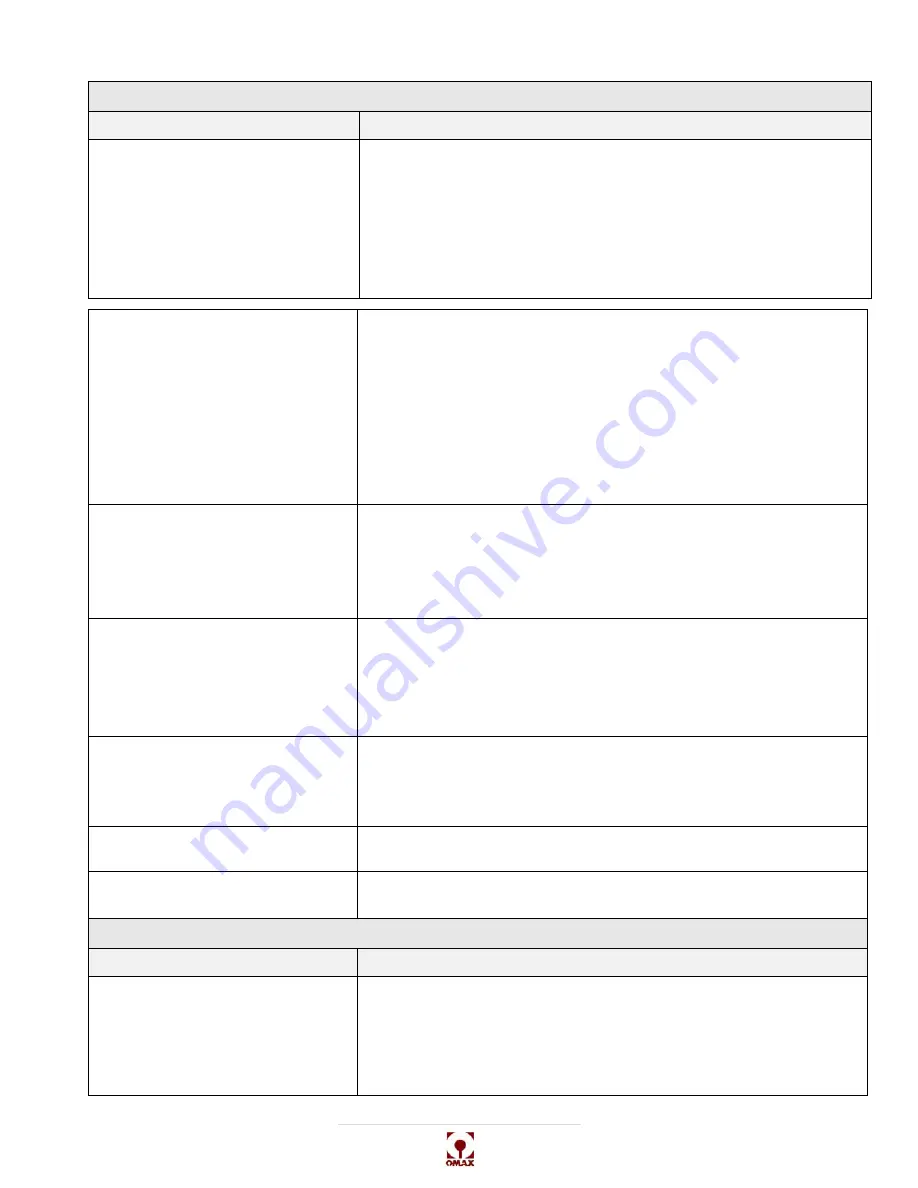

Abrasivejet Not Piercing Material

Condition and Possible Causes

Corrective Action

Setup values entered in Make are not

consistent with the actual physical

requirements.

Check that the material setup values for the following parameters are

correctly set in Make:

• Machinability —

Thickness

Click on

Setup

in Make, choose

Pump and Nozzle settings

, and verify

that values for the following parameters are set correctly:

• Water pressure

• Orifice diameter

• Mixing tube diameter

• Abrasive flow rate

An abrasive other than the

recommended garnet is being used.

Many abrasives do not cut as well as garnet, and the machinability should

be reduced when using these abrasives. It may be necessary to

experiment to determine the best settings.

Garnet is recommended because it allows a good cutting rate with

relatively low mixing tube wear. Garnet is also nonhazardous and, as such,

is easily disposed. Other abrasives may increase mixing tube wear and

may be a disposal hazard.

WARNING!

Never use silica sand as a cutting abrasive. Fine silica

dust produced by the cutting process can lead to

silicosis, a serious lung disease.

The standoff between the abrasivejet

nozzle and the material being cut is

too high.

The standoff should be no more than 0.050" (1.3 mm) for best results.

Note:

In Make, under Motion Preferences, it is possible to set the

pierce height to be different from the cutting height if you have a

motorized Z-axis. To help reduce nozzle plugging, consider

setting the pierce height higher than the cutting height.

The abrasive flow is stopped or has

been reduced by the presence of dirt

or wet abrasive.

Disassemble the plugged items, blowing them clean and dry with an air

hose.

WARNING!

Never point the air stream at anyone during the

cleaning process. Always wear eye protection!

The mixing tube has worn excessively

and is unable to form a perfect jet.

Mixing tube wear occurs first at the inlet, then a conical wear zone grows

toward the exit end of the mixing tube. Check the tube bore at both ends

using a drill or gage pin. When the outlet diameter has increased by 0.005"

(0.13 mm), the mixing tube is near the end of its useful life for precise

cutting.

The jewel that forms the jet is

chipped, dirty or out of tolerance.

Replace the jewel and the jewel holder.

The pump is not delivering the

pressure specified.

Measure the pressure to see if it is below specification.

Follow the pump troubleshooting procedures.

Abrasivejet Quit Cutting

Condition and Possible Causes

Corrective Action

The abrasive flow is stopped or has

been reduced by the presence of dirt

or wet abrasive.

Disassemble the plugged items, blowing them clean and dry with an air

hose.

WARNING!

Never point the air stream at anyone during the

cleaning process. Always wear eye protection!

Summary of Contents for JetMachining Center 2626

Page 8: ...OMAX JetMachining Center Operator s Guide viii 400433D EN ...

Page 12: ...OMAX JetMachining Center Operator s Guide xii 400433D EN ...

Page 22: ...OMAX JetMachining Center Operator s Guide Safety First 1 10 400433D EN ...

Page 140: ...OMAX JetMachining Center Operator s Guide OMAX Glossary 6 16 400433D EN ...

Page 144: ...OMAX JetMachining Center Operator s Guide Index 4 400433D EN ...