OMAX JetMachining® Center Operator’s Guide

vi

400433D-EN

Tips for Effective Cutting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 9

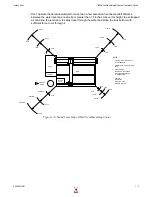

Setting Soft Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 10

Auto Homing Your Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 10

Configuring Your Drawing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 11

Cutting Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 12

Setting Up the Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 12

Configuring the Make Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 19

Cutting the Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 20

Shutting Down the JetMachining Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 21

Startup Checkoff Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 23

Shutdown Checkoff Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 24

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

Main Electric Motor Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

Changing Crankcase Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

Routine Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

Less Frequent Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

Nozzle Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 4

Identifying When to Repair and Rebuild the Nozzle . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 4

Preparing for Nozzle Repair/rebuild . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 4

Removing a MaxJet® 5 Nozzle Assembly from a Tilt-A-Jet . . . . . . . . . . . . . . . . . . . . 4 - 5

Removing the Nozzle Mixing Tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 6

Removing the Nozzle Body from the Inlet Body . . . . . . . . . . . . . . . . . . . . . . . . 4 - 6

Removing the Filter Seal Assembly from the Inlet Body. . . . . . . . . . . . . . . . . . . 4 - 7

Removing the Orifice Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 7

Removing the Mixing Chamber Disc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 8

Removing the Mixing Chamber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 8

Removing the Nozzle Body O-Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 9

Cleaning and Inspecting Nozzle Components . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 9

Nozzle Filter Seal Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 14

Mixing Chamber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 15

Mixing Chamber Disc and Orifice Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 16

Nozzle Body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 17

Mixing Tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 19

Nozzle Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 20

Maximizing Nozzle Life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 20

Removing and Reinstalling the Inlet Body on a Tilt-A-Jet. . . . . . . . . . . . . . . . . . . . . . 4 - 22

Removing a Stuck Inlet Body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 24

Cleaning the Inlet Body. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 25

Reinstalling the Inlet Body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 26

Removing and Reinstalling a Mini-MaxJet 5 Nozzle Assembly . . . . . . . . . . . . . . . . . 4 - 28

Disassembling a MiniJet Nozzle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 28

Step 2: Remove the MiniJet Nozzle Body from the Inlet Body Extension . . . . . 4 - 29

Step 3: Remove the Inlet Body Extension from the Inlet Body . . . . . . . . . . . . . . 4 - 29

Step 4: Remove the MiniJet Dummy Orifice from the Inlet Body . . . . . . . . . . . . 4 - 30

Step 9: Remove Ring Seals and O-Rings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 31

Setting the Adjustable Dump Orifice (ADO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 35

Changing the Dump Valve Orifice Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 39

Disassemble the Dump Valve and Removing the Orifice Assembly . . . . . . . . . 4 - 39

Reassembling the Dump Valve With Replacement Orifice Assembly . . . . . . . . 4 - 42

Summary of Contents for JetMachining Center 2626

Page 8: ...OMAX JetMachining Center Operator s Guide viii 400433D EN ...

Page 12: ...OMAX JetMachining Center Operator s Guide xii 400433D EN ...

Page 22: ...OMAX JetMachining Center Operator s Guide Safety First 1 10 400433D EN ...

Page 140: ...OMAX JetMachining Center Operator s Guide OMAX Glossary 6 16 400433D EN ...

Page 144: ...OMAX JetMachining Center Operator s Guide Index 4 400433D EN ...