OMAX JetMachining® Center Operator’s Guide

Maintenance

4 - 14

400433D-EN

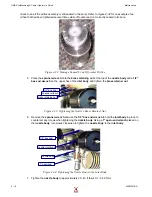

Mixing Chamber

The mixing chamber is an infrequent consumable item but may need to be replaced if the internal

diameter of the mixing chamber hole has grown larger than 0.026" (0.66 mm) or if it shows excessive

oblong wear.

Figure 4-20: Worn Mixing Chamber

Reassembling the Nozzle Assembly

1.

After cleaning, inspecting, and obtaining replacement

nozzle

components

, you are ready to

reassemble the

nozzle assembly

and re-install it on the machine.

2.

Purge the

high-pressure plumbing

to flush out any particles or contamination using the

nozzle test

with the

Water

only,

Low

pressure options (see Figure 4-18 for test menu). Repeat this test two or

three times.

Figure 4-21: Purging the High-pressure System of Contaminates with the Nozzle Removed

Caution:

Make sure you maintain cleanliness throughout the nozzle reassembly and installation

process. Any contamination that gets into the nozzle components during reassembly will

negatively impact the cutting performance and shorten the life of the nozzle components.

Nozzle Filter Seal Assembly

1.

Insert the

nozzle filter seal assembly

into the

inlet body

:

Figure 4-22: Nozzle Filter Seal Assembly

2.

Apply a light coating of

Lubriplate

to the filter’s

o-ring

.

3.

Slide the lubricated

o-ring

onto the

filter

.

worn areas

o-ring

filter

Summary of Contents for JetMachining Center 2626

Page 8: ...OMAX JetMachining Center Operator s Guide viii 400433D EN ...

Page 12: ...OMAX JetMachining Center Operator s Guide xii 400433D EN ...

Page 22: ...OMAX JetMachining Center Operator s Guide Safety First 1 10 400433D EN ...

Page 140: ...OMAX JetMachining Center Operator s Guide OMAX Glossary 6 16 400433D EN ...

Page 144: ...OMAX JetMachining Center Operator s Guide Index 4 400433D EN ...