OMAX JetMachining® Center Operator’s Guide

Maintenance

4 - 32

400433D-EN

7.

Place a

1/2" wrench

on the

inlet body

at the top of the nozzle assembly to hold the

inlet body

in

place and counteract any induced torque when installing the

inlet body extension

. This prevents

any induced torque from affecting the Tilt-A-Jet’s alignment and accuracy.

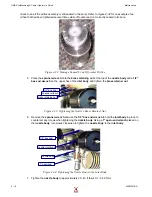

Figure 4-66: Tightening the Inlet Body Extension to the Inlet Body

8.

Using a

1-1/8" open-end wrench

placed on the

inlet body extension

, tighten the right-hand

threaded Inlet

body extension

to the

inlet body

using both wrenches (Figure 4-66).

9.

Tighten the

inlet body extension

to approximately 30 - 40 ft. lbs. (40.7 - 54.2 Nm).

10. In the MiniJet

nozzle body

, ensure that the

orifice assembly

and

mixing chamber disc

are

properly installed and can seat as required with the

inlet body extension

.

Figure 4-67: Inspecting for Properly Seated Orifice Assembly and Mixing Chamber Disc

11. Apply

Blue Goop

to the internal and external threads of the

MiniJet nozzle body

.

12. Hand tighten the

MiniJet nozzle body

onto the

inlet body extension

.

Figure 4-68: Hand Tightening MiniJet Nozzle Body to the Inlet Body Extension

13. Place a

1-1/8" open-end wrench

on the

inlet body extension

to hold the

inlet body extension

in place and counteract any induced torque when installing the

MiniJet nozzle body

.

inlet body extension

1-1/8" open-end

1/2" wrench on

inlet body

blue goop

MiniJet nozzle body

orifice assembly

blue goop internal and

external body threads

MiniJet nozzle body

inlet body extension

Summary of Contents for JetMachining Center 2626

Page 8: ...OMAX JetMachining Center Operator s Guide viii 400433D EN ...

Page 12: ...OMAX JetMachining Center Operator s Guide xii 400433D EN ...

Page 22: ...OMAX JetMachining Center Operator s Guide Safety First 1 10 400433D EN ...

Page 140: ...OMAX JetMachining Center Operator s Guide OMAX Glossary 6 16 400433D EN ...

Page 144: ...OMAX JetMachining Center Operator s Guide Index 4 400433D EN ...