Introduction

OMAX JetMachining® Center Operator’s Guide

400433D-EN

2 - 9

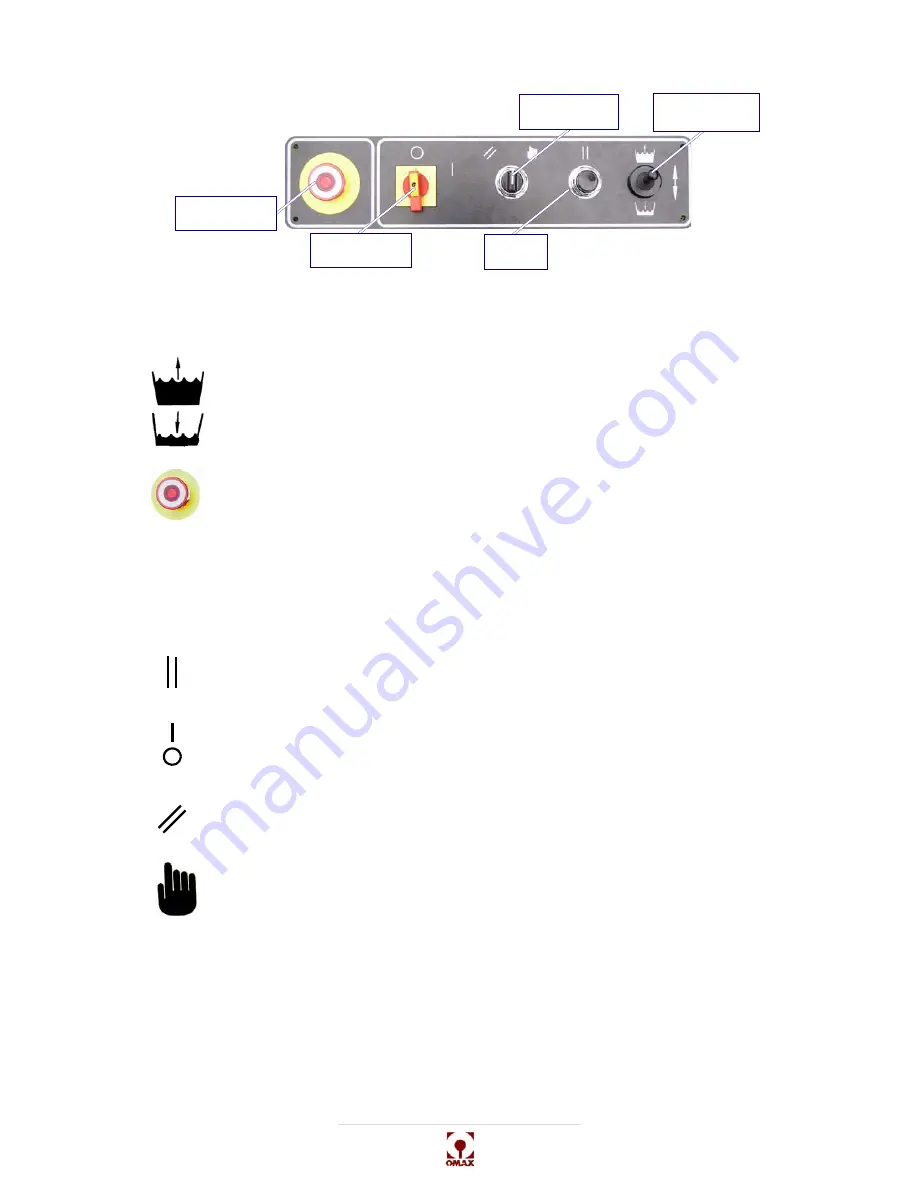

Figure 2-12: Control Panel Operator Switches

Control Panel Switches

X-Y Table

The X-Y table on OMAX models 2626, 2626|xp, 2652, 5555, and 55100 consists of a bridge X-axis and

a cantilever Y-axis rigidly mounted to the cutting table. A series of steel slats provide vertical support for

the parts being machined.

The 80160 X-Y table consists of a Y-axis bridge attached to dual X-axis rails rigidly mounted to the

catcher tank. The Y beam is connected to the carriage that moves along the X beam. Both the X and Y

Water Level

Raises (

K

) and lowers (

) the water in the catcher tank to cover/uncover the

material being cut.

Emergency Stop

Immediately shuts down the water pump and abrasivejet operation. The

emergency stop (E-stop) should be used only for real emergencies. When

pressed, the OMAX loses important machine positioning information.

Caution:

The abrasive feed line must always be cleaned out after using the

Emergency stop switch!

Pause

Pauses motion and shuts down the abrasivejet nozzle. Machining can be

restarted without any loss of machine positioning information.

Power On/Off

Turning this switch to its On ( | ) position after the pump has been powered up,

automatically starts the computer.

Reset

Reset disables all servo motors and resets any faulted drive.

Servo Motor Override

This override function is for diagnostic purposes only and is

not for normal

operation

.

Reset/Override

switch

Pause

switch

emergency stop

switch (E-stop)

Water Lever Up/

Down switch

controller power

On/Off switch

Summary of Contents for JetMachining Center 2626

Page 8: ...OMAX JetMachining Center Operator s Guide viii 400433D EN ...

Page 12: ...OMAX JetMachining Center Operator s Guide xii 400433D EN ...

Page 22: ...OMAX JetMachining Center Operator s Guide Safety First 1 10 400433D EN ...

Page 140: ...OMAX JetMachining Center Operator s Guide OMAX Glossary 6 16 400433D EN ...

Page 144: ...OMAX JetMachining Center Operator s Guide Index 4 400433D EN ...