OMAX JetMachining® Center Operator’s Guide

Operation

3 - 6

400433D-EN

Drawing the Part Using Layout

The Layout software is a drawing program that creates parts using lines, arcs, and shapes such as for

rectangles and circles. Once drawn, a cutting speed (quality) is assigned to each segment of the

drawing. The higher the quality chosen, the slower the cutting speed.

Layout can open files from other drawing programs. Drawings in the DXF format can be imported. Parts

can also be created from photographs and other drawing sources using Layout’s tracing capabilities.

Setting the Tool Path

After a part’s drawing is created, Layout’s

Generate Tool Path

command creates a tool path that

defines how the part will be cut. In most cases, this command creates the exact tool path wanted, but

you can always modify the path manually when needed.

Making the Part

Once the tool path is created, the Make software can control movement of the abrasivejet and the cutting

of your part. Before beginning the machining operation, you can preview how the part will be made, how

long it will take to make the part, and the amount of abrasive required.

Determining Quality

Each entity in a drawing is assigned a quality value (1-5) which controls how quickly the abrasivejet

nozzle moves when it cuts the piece. The slower the abrasivejet nozzle moves, the higher the quality of

a cut. At the highest quality (5), the abrasivejet nozzle moves the slowest. Quality also takes into account

the material being cut. When working with a softer material such as polypropylene, for example, a quality

of 5 moves the abrasivejet nozzle much faster than a quality of 5 would while working with steel. Quality

is always relative to the machinability of the material.

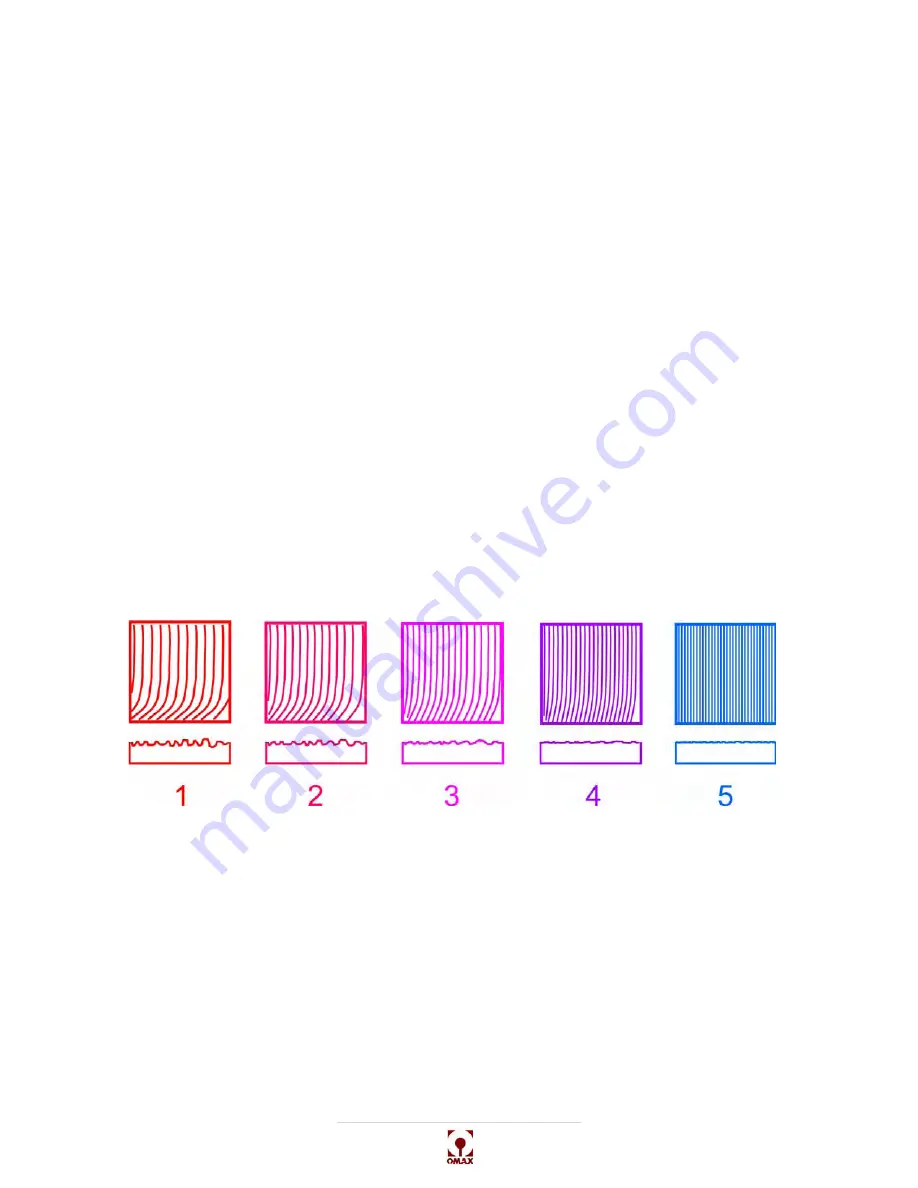

Figure 3-3 shows how the surface finish changes with the quality assigned. As the quality number goes

lower, the cutting speed becomes faster, and the cut surface becomes less and less smooth.

Figure 3-3: Quality Examples

In most cases, setting the cutting quality is a compromise between achieving the best surface finish in

the least amount of time. When deciding which quality to use on a new material, a quality of 3 is a good

choice. If the finish is too rough, increase the quality number. If the finish is acceptable, try lowering the

quality to see if the part can be made in less time.

Four of the available types of qualities—Etch, Scribe, Water Only, and Lead—are different types of

qualities. Etch and Scribe are designed to mark the surface of a material (to add a part number, for

example). Water Only is designed for materials that can be machined without add an abrasive. Lead is

assigned to a cutting path’s lead-ins and lead-outs.

Clamping and Positioning Materials for Cutting

Large clamping forces are not ordinarily needed to secure material to the cutting table, but the material must

not be allowed to move as it is being machined. One of the primary causes for out-of-tolerance parts is

allowing the material to move while being cut.

Summary of Contents for JetMachining Center 2626

Page 8: ...OMAX JetMachining Center Operator s Guide viii 400433D EN ...

Page 12: ...OMAX JetMachining Center Operator s Guide xii 400433D EN ...

Page 22: ...OMAX JetMachining Center Operator s Guide Safety First 1 10 400433D EN ...

Page 140: ...OMAX JetMachining Center Operator s Guide OMAX Glossary 6 16 400433D EN ...

Page 144: ...OMAX JetMachining Center Operator s Guide Index 4 400433D EN ...