OMAX JetMachining® Center Operator’s Guide

Maintenance

4 - 8

400433D-EN

Removing the Mixing Chamber Disc

The

mixing chamber disc

sits directly beneath the

orifice assembly

. To remove the

mixing

chamber disc

, gently strike the

nozzle body

onto the palm of your hand, forcing the

disc

to release

from the

nozzle body

.

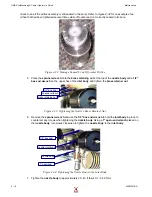

Figure 4-7: Removed Orifice Assembly and Mixing Chamber Disc

Note:

If the mixing chamber disc does not easily fall out of the nozzle body, carefully blow compressed air into

the abrasive inlet, ensuring that the disc will fall out into your hand or onto a soft surface to avoid cracking

or breaking. If compressed air does not remove the disc, carefully push down on the disc from the mixing

tube end of the nozzle body using a 3/16" Allen wrench or similar device suitable for pushing.

Removing the Mixing Chamber

The mixing chamber is an infrequent wear item.

1.

Inspect the

mixing chamber

prior to removing it.

2.

If the

mixing chamber

needs to be replaced, clean the area above the chamber.

3.

Press the

mixing chamber

out of the

nozzle body

using the

arbor press

and an old

mixing tube

(or similar device) as a pushing tool.

Figure 4-8: Pressing the Mixing Chamber from the Nozzle Body

Note:

To facilitate removal of the mixing chamber, it may be necessary to heat the nozzle body using either a

heat gun, boiling water, or similar heating technique. It will not be necessary to remove the inlet body from

the machine unless leakage is noted in this area.

orifice assembly

mixing

chamber disc

arbor press

old mixing tube

nozzle body

mixing chamber

Summary of Contents for JetMachining Center 2626

Page 8: ...OMAX JetMachining Center Operator s Guide viii 400433D EN ...

Page 12: ...OMAX JetMachining Center Operator s Guide xii 400433D EN ...

Page 22: ...OMAX JetMachining Center Operator s Guide Safety First 1 10 400433D EN ...

Page 140: ...OMAX JetMachining Center Operator s Guide OMAX Glossary 6 16 400433D EN ...

Page 144: ...OMAX JetMachining Center Operator s Guide Index 4 400433D EN ...