Maintenance

OMAX JetMachining® Center Operator’s Guide

400433D-EN

4 - 15

4.

Push the

filter

with

o-ring

installed up into the

inlet body

.

Figure 4-23: Filter Seal Assembly Inserted into Inlet Body

Note:

The nozzle filter seal assembly will be properly seated when the nozzle body is tightened.

Mixing Chamber

1.

Place a small dab of

extreme pressure lube

onto a finger tip and lubricate the outside of the

mixing chamber

.

2.

Place the

mixing chamber

in the

nozzle body

with its groove aligned with the abrasive inlet hole:

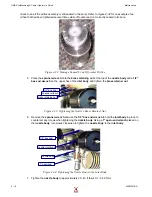

Figure 4-24: Locating the Mixing Chamber Groove and Abrasive Inlet Hole for Alignment

Note:

An assembly trick is to mark the top edge of the nozzle body with a marker to identify where the abrasive

inlet hole is located when lining up the mixing chamber.

3.

Screw the

mixing tube retainer nut

onto the

nozzle body threads

to prevent thread damage, or

place a

1" deep-well socket

over the 1" hex on the

nozzle body

for support (Figure 4-25).

4.

Place the

nozzle body

in the

arbor press

and press the

mixing chamber

into the nozzle body

bore using the

0.550" push tool

and a

1" deep-well socket

.

Figure 4-25: Using the Push Tool and Arbor Press to Insert the Mixing Chamber into the Nozzle Body

Note:

If you have trouble inserting the mixing chamber, placing it in a freezer prior to insertion makes it easier to

fit into a tight nozzle body.

5.

Measure the internal depth of the remaining bore in the

nozzle body

from the top of the bore to

the top of the

mixing chamber

. This gap must measure approximately 0.130" (3.3 mm) in order to

accommodate the

mixing chamber disc

and

orifice assembly

when inserted.

filter installed

in inlet body

mixing chamber

groove

abrasive

inlet hole

1" deep

well socket

push tube

nozzle body

arbor press

Summary of Contents for JetMachining Center 2626

Page 8: ...OMAX JetMachining Center Operator s Guide viii 400433D EN ...

Page 12: ...OMAX JetMachining Center Operator s Guide xii 400433D EN ...

Page 22: ...OMAX JetMachining Center Operator s Guide Safety First 1 10 400433D EN ...

Page 140: ...OMAX JetMachining Center Operator s Guide OMAX Glossary 6 16 400433D EN ...

Page 144: ...OMAX JetMachining Center Operator s Guide Index 4 400433D EN ...