OMAX JetMachining® Center Operator’s Guide

Maintenance

4 - 26

400433D-EN

Reinstalling the Inlet Body

1.

Apply a light coating of

Blue Goop

to the male threads of the

inlet body

and to the bore diameter

around the

inlet cone

to minimize water deposit buildup around the

inlet body

.

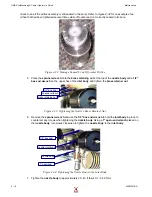

Figure 4-51: Applying Blue Goop to the Inlet Body Male Threads and Bore Diameter

2.

Insert the

inlet body

through the

tilting plate

. Screw the

brass retaining nut

onto the

inlet body

and hand-tighten it to the

tilting plate

. Rotate the

inlet body

until the hole in the

inlet body

appears in the center of the hole in the

tilting plate

.

Note:

Only hand-tighten at this time to allow the On/Off Valve and high-pressure plumbing to be properly aligned

in the steps that follow.

Figure 4-52: Hand Tightening the Inlet Body and Aligning to Tilting Plate Hole

3.

Apply a small amount of

anti-seize

to the threads on each of the 4

Allen-head screws

.

4.

Apply

Blue Goop

to the fitting threads and the

on/off valve body seat

.

Figure 4-53: Applying Blue Goop and Anti-seize Compounds to Valve Body Components

blue goop on

threads

blue goop bore

diameter

inlet body

blue goop on

threads

inlet body

tilting plate

brass retaining

ring

inlet body hole

appearing in center

of tilting plate hole

blue goop on threads of

body adapter fitting

blue goop to on/off

valve body seat

anti-seize on threads

of 4 Allen screws

valve body

Summary of Contents for JetMachining Center 2626

Page 8: ...OMAX JetMachining Center Operator s Guide viii 400433D EN ...

Page 12: ...OMAX JetMachining Center Operator s Guide xii 400433D EN ...

Page 22: ...OMAX JetMachining Center Operator s Guide Safety First 1 10 400433D EN ...

Page 140: ...OMAX JetMachining Center Operator s Guide OMAX Glossary 6 16 400433D EN ...

Page 144: ...OMAX JetMachining Center Operator s Guide Index 4 400433D EN ...