8

Installation

TRANSPORT

Transport shall be carried out by qualified personnel so as to avoid any damage to the machine and any of its

components. In particular:

•

All the guards, covers and doors must be properly closed and secured.

• Use a forklift or transpallet with sufficiently long forks and loading capacity.

The load bearing capacity of the forklift truck must be more than the weight of the machine; check this

capacity on the plates affixed on the forklift truck and in the operating instructions.

The machine should be transported on a flat and solid floor only, free of unevenness.

INSTALLATION

The machine must be positioned on a hard and level floor. Connection to the power supply must be carried out

in accordance with the current standards and taking into account the necessary measures in order to avoid the

dangers of indirect contact and overcurrent. Also check that:

• The supply voltage is 400 V on the input terminals (L1 - L2 - L3) located inside the electrical control panel.

•

The machine’s connection to ground is, in fact, connected to the company grounding system.

Make sure the cutter is placed in a sufficiently lit work area (min. 300 lux). Check that there is enough space

around the machine to move the removable parts and that it is easily accessible for routine and extraordinary

maintenance (at least 500 mm of free space besides the dimensions of removable parts)

PRELIMINARY CHECK PRIOR TO STARTING-UP

Once the machine has been connected to the mains the following check is necessary:

1.

Using the jog mode, press the two hand control device (push buttons P), to check that the cutting wire

moves down towards the work top.

2.

If the wire moves upwards instead, reverse the electrical connections in the plug (reverse the phase).

3.

Now check again.

If it is necessary to reverse the phase you must first disconnect the electricity (take the plug out of the

socket/open the omnipolar switch directly upstream). In all cases this must be done by a specifically

skilled electrician.

The machine is equipped for the earth-connection of conductive metal masses. The connection must

be ensured and carried out correctly in accordance with applicable technical standards. The machine

cannot be used if it is not earthed.

Operations on electrical equipment must only be carried out by qualified technical personnel with

the necessary electrical engineering skills, after referring to the wiring diagram and the necessary

conditions in order to avoid electrocution.

Summary of Contents for 45412

Page 18: ...18 Electrical Schematics Model GR IT 1000 C 45412 Main Disconnector...

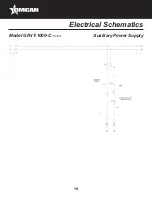

Page 19: ...19 Electrical Schematics Model GR IT 1000 C 45412 Auxiliary Power Supply...

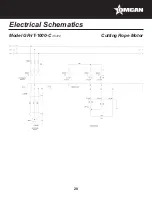

Page 20: ...20 Electrical Schematics Model GR IT 1000 C 45412 Cutting Rope Motor...

Page 21: ...21 Electrical Schematics Model GR IT 1000 C 45412 Forward Contactor...

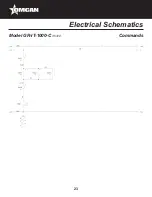

Page 22: ...22 Electrical Schematics Model GR IT 1000 C 45412 Commands...

Page 23: ...23 Electrical Schematics Model GR IT 1000 C 45412 Commands...

Page 24: ...24 Electrical Schematics Model GR IT 1000 C 45412 Machine Safety Relays...

Page 25: ...25 Electrical Schematics Model GR IT 1000 C 45412 Machine Safety Devices...

Page 26: ...26 Electrical Schematics Model GR IT 1000 C 45412 Machine Contemporary Relay...

Page 27: ...27 Electrical Schematics Model GR IT 1000 C 45412 Push Buttons...