14

Cleaning and Maintenance

to visible lines. Use a plastic scouring pad or soft cloth when grain is not visible.

3. Use alkaline, alkaline chlorinated or non-chloride containing cleaners. While many traditional cleaners are

loaded with chlorides, the industry is providing an ever increasing choice of non-chloride cleaners. If unsure

of chloride content contact the cleaner supplier. If present cleaner contains chlorides, ask for an alternative.

Avoid cleaners containing quaternary salts as they can attack stainless steel causing pitting and rusting.

4. Water treatment. To reduce deposits, use soft water whenever possible. Installation of certain filters can be

an advantage. Contact a treatment specialist about proper water treatment.

5. Maintain cleanliness of food equipment. Use cleaners at recommended strength(alkaline, alkaline

chlorinated or non-chloride). Avoid buildup of hard stains by cleaning frequently.

6. When using chlorinated cleaners you must rinse and wipe dry immediately. It is better to wipe standing

cleaning agents and water as soon as possible. All stainless steel equipment to air dry. Oxygen helps

maintain the passivity film on stainless steel.

7. Hydrochloric acid (muriatic acid) should never be used on stainless steel.

8. Regularly restore/clean stainless steel.

KEG BEER LINE CLEANING

1. Tools needed.

2. Pour cleaning solution and water into the pump bottle and connect it to the beer line.

3. Place a bucket under the faucet and open the beer faucet. Pump to remove the cleaning solution and

water. Continue to pump until all cleaning solution has exited. You can also fill the line and let it soak then

run through the line. After you have run the cleaning solution through, open the bottle and fill with water.

Repeat water rinsing until the line is free of cleaning chemicals.

REFERENCE

Item Number Model Number

Description

Manufacturer Model Number

50058

BB-CN-0012-GH

Cooler Back Bar 11.8 cu ft Glass Door

115V/60/1 ETL cETLus INTERTEK

UBB-24-48G-HC

50060

BB-CN-0016-GH

Cooler Back Bar 15.8 cu ft Glass Door

115V/60/1 ETL cETLus INTERTEK

UBB-24-60G-HC

50062

BB-CN-0020-GH

Cooler Back Bar 19.6 cu ft Glass Door

115V/60/1 ETL cETLus INTERTEK

UBB-24-72G-HC

50057

BB-CN-0012-SH

Cooler Back Bar 11.8 cu ft Solid Door

115V/60/1 ETL cETLus INTERTEK

UBB-24-48F-HC

50059

BB-CN-0016-SH

Cooler Back Bar 15.8 cu ft Solid Door

115V/60/1 ETL cETLus INTERTEK

UBB-24-60F-HC

50061

BB-CN-0020-SH

Cooler Back Bar 19.6 cu ft Solid Door

115V/60/1 ETL cETLus INTERTEK

UBB-24-72F-HC

Summary of Contents for BB-CN-0012-SH

Page 18: ...18 Parts Breakdown Model BB CN 0020 GH 50062 Model BB CN 0020 SH 50061...

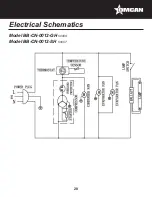

Page 20: ...20 Electrical Schematics Model BB CN 0012 GH 50058 Model BB CN 0012 SH 50057...

Page 21: ...21 Model BB CN 0016 GH 50060 Model BB CN 0016 SH 50059 Electrical Schematics...

Page 22: ...22 Electrical Schematics Model BB CN 0020 GH 50062 Model BB CN 0020 SH 50061...