15

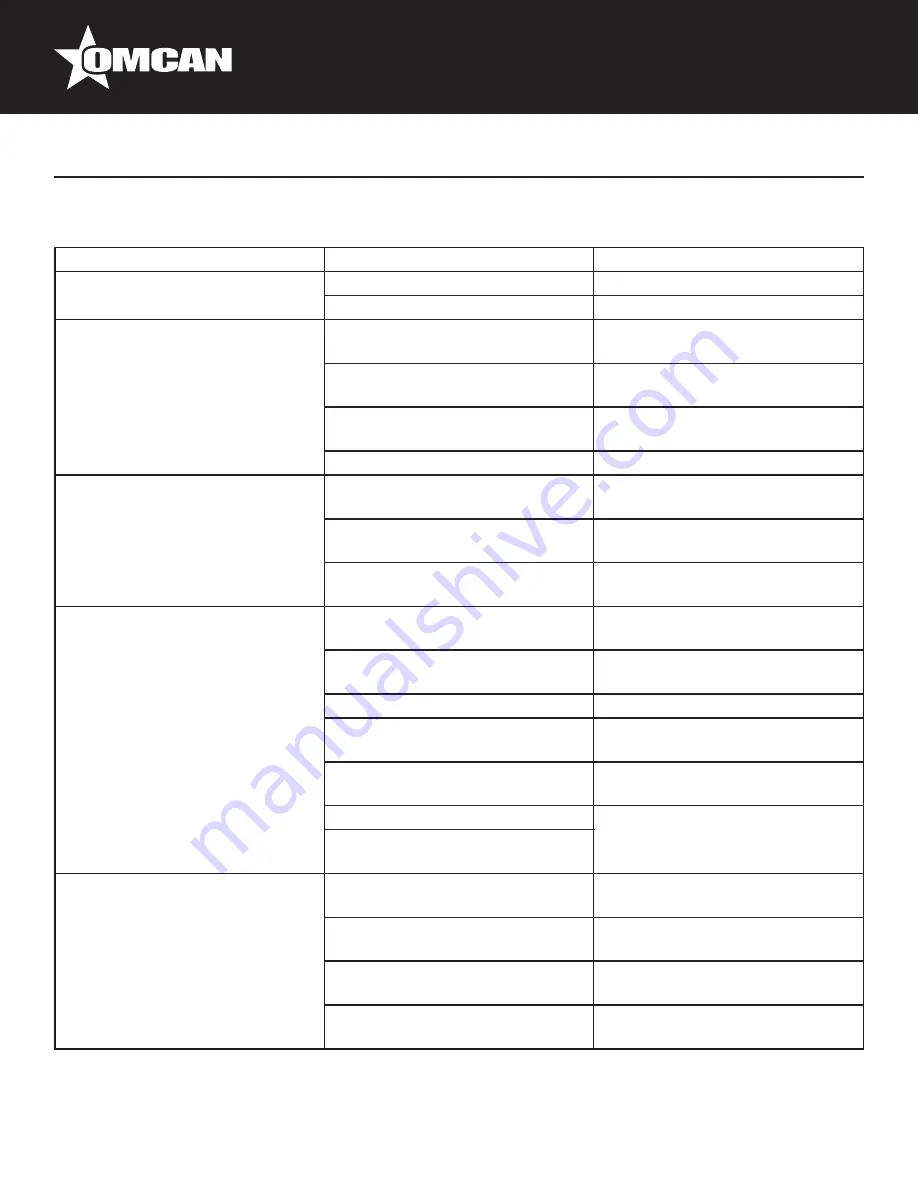

Troubleshooting

COMMON FAULTS AND TROUBLESHOOTING

Fault

Potential cause

Troubleshooting

Not working / Indicator is “OFF”.

Power switch not turned on.

Turn on the power switch.

Plug is loose.

Check plug and socket.

The display shows E04 high

temperature / The display shows

E06 high pressure protection.

The ambient temperature is too

high.

Normal working temperature range

of 5-32°C.

Condenser or air filter is dirty and

blocked.

Clean the condenser and air filter.

High pressure switch wires fallen

off.

Check and correct high pressure

switch wires.

Fan does not start.

Check and correct the fan.

Ice defrost abnormal.

Ambient temperature too low.

Normal working temperature range

of 5-32°C.

Defrost valve does not start

normally.

Check and correct the defrosting

valve.

Ice thickness too thin or too thick.

Check and correct ice thickness

setting.

Poor transparency of ice cubes; ice

cubes too thin or incomplete.

Ice thickness too thin.

Check and correct ice thickness

setting.

Water pressure too low.

Check that the water supply

pressure is 1.3 Bar to 5.5 Bar.

Water temperature too high.

Water temperature of 5-35°C.

Inlet water valve does not work.

Check and correct the inlet water

valve.

Inlet water valve is dirty and

blocked.

Check whether water leaks and

correct.

Water leaking.

Check and correct the inlet water

filter.

Inlet water filter has not been

replaced for a long time.

Too slow in ice making.

The condenser or air filter is dirty.

Clean the condenser and filter

screen.

High ambient temperature.

Normal working temperature range

of 5-32°C.

Poor ventilation.

Check the environment around the

ice machine.

Water temperature is too high.

Check the water supply

temperature of 5-35°C.