7

Installation and Operation

GRINDING GROUP ASSEMBLY / DISASSEMBLY

The assembly / disassembly operations of any machine part are performed with the machine in the OFF

position, and the plug disconnected from the socket.

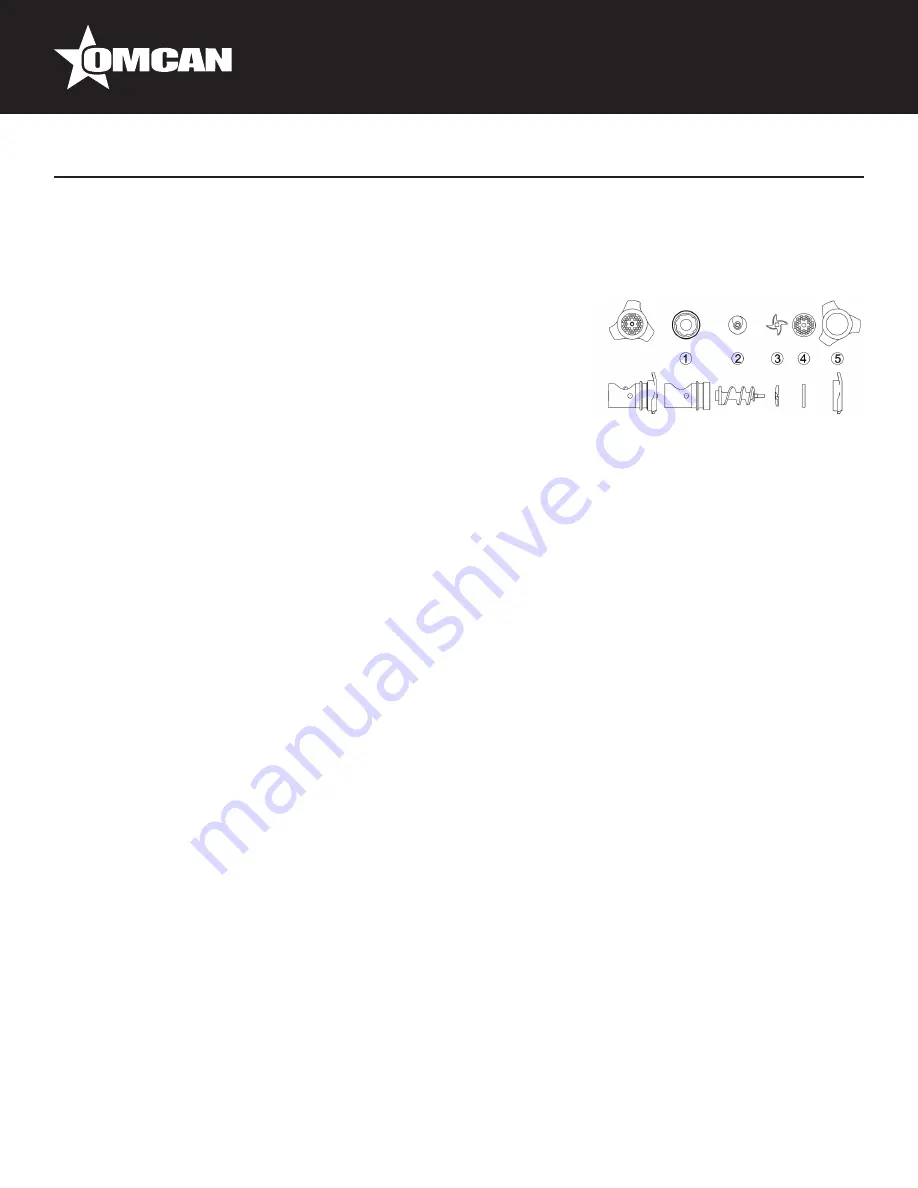

To assemble the grinder, do the following steps in this order:

1. Insert into the shaft (1) in order: the worm (2), the cutting knife oriented

as shown in the figure (3), and the plate (4).

2. Screw down and tighten the screw (5).

To disassemble, do the above procedure in the reverse order.

OPERATION INSTRUCTIONS

STARTING THE MACHINE

To start the machine, the switch has to be placed on the “I” position.

STOPPING THE MACHINE

To stop the machine, the switch has to be placed on the “O” position.

FUNCTIONING SAFETY

If the machine is under stress, operated for a long period of time or overloaded, it will stop immediately when

the thermal protection turns on. In this case wait for the unit to cool completely before using again.

OPERATION

The machine operator can begin operation of the machine when:

1. The machine is installed properly.

2. The machine is connected to the electrical supply.

3. The hopper is inserted in the correct position.

4. The grinding group assembly is installed correctly.

5. The worm rotates in the correct direction.

6. Tests the switch.

7. Check that all safety conditions are being met.

8. Check that the plug is in the correct socket.

9.

Place a collecting tray below the shaft to collect the final product.

10. Start the machine by placing the switch to the “I” position.

11. Manually introduce the chopped meat into the machine neck and use the supplied stomper to push the

meat into the shaft.

12. Once the operation is completed, or when the product no longer comes out of the plate, place the switch to

the “O” position to stop the machine.

It is recommended to only operate the machine when there is product in the unit.