9. Use and maintenance manual

B01.13

San Maurizio C.se - 23/11/2018

www.omcr.it

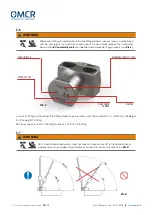

At the moment of the assembling, carefully clean the contact surfaces between lifting

brackets and steel plates.

The presence of oil or dirt on the contact surface between the lifting bracket and the mold

holder plate may compromise the correct functioning of the lifting bracket

WARNING

4.2.1

5. MAINTENANCE

5.1

Every 6 months inspect visually the lifting brackets, paying particular attention to any evidence of

deformations or oxidation: in case restore or replace the lifting brackets.

5.2

Every 6 months check the correct clamp of the fixing screws in accordance with the table included in this manual.

5.3

In case of suddenly settlements of lifting ropes/chains with a following overload on the lifting brackets,

inspect visually the lifting brackets, paying particular attention to any eventual evidence of deformations and,

in case replace them; replace the fixing screws and check the correct clamp in accordance with the table

included in this manual.

5.4

In case of unforeseen settlements of lifting ropes with a following overload on the lifting bracket, make visual

tests on the lifting brackets to check eventual deformations and, in case of these last ones, substitute them;

substitute the fixing screws and check the correct clamp following the table indicated in this manual.

5.5

In case of accidental impacts in the sling-zone during the lifting and handling, make visual inspections on

the lifting brackets to check eventual deformations and, in case replace them; replace the fixing screws and

check the correct clamp in accordance with the table included in this manual.