CDi-16B - Installation and operating manual

www.omega-air.si

2

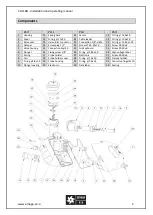

Components

Part

Part

Part

Part

1

Housing

11 Spring base

21 Sensor

31 O-ring

12,0x2,0

2

Cover

12 O-ring

17x2,0

22 Cable leader

32 O-ring

10,0x2,0

3

Valve seat

13 Valve inlet connector

23 Connection 1/8”-

8/6

33 O-ring

21,95x1,78

4

Damper

14 Screw plug 1/2”

24 Screw PT KA 35x16

34 Screw KA 30x8

5

Valve housing

15 Connection Al

50

25 Foil keyboard

35 Screw KA 30x8

6

Plunger

16 Fixing screw 1/8”

26 O-ring

38,0x3,0

36 High voltage label

7

Spring

17 Probe holder

27 Electronic

37 Screw KA 30x6

8

Coil

18 Probe holder cover

28 O-ring

7,0x2,0

38 Flat seal

10x1

9

O-ring

5,8x1,5 19 Probe housing

29 O-ring

9,0x1,5

39 Contact spring

2x10

10 Plunger sealing

20 Electronic

30 Data label

40 Sealing