CDi-16B - Installation and operating manual

www.omega-air.si

4

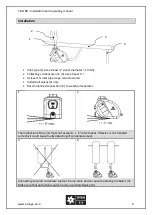

Safety instructions

Depressurize the system before carrying out any work on the piping or CDi-16B.

Installation and maintenance work may only be carried out when the device is not

under pressure.

Installation and maintenance work may only be carried out by trained and

experienced stuff.

Disconnect power supply before installation or any maintenance work.

Electrical work must always be carried out by qualified electrician.

Do not exceed max. operating pressure or operating temperature range (

see data

label

).

Do not use the device in hazardous areas with potentially explosive atmospheres.

Use original spare parts only.

Use the device for the appropriate purpose only.

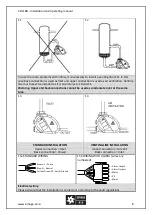

Appropriate use

CDi-16B series electronic condensate drains are intended exclusively for draining

condensate from compressed air system (air compressors, air receivers/pressure

vessels, air dryers and air filters). This appliance must be used only for the

purpose for which it was specifically designed. All other uses are to be considered incorrect.

The manufacturer cannot be held responsible for any damage resulting from improper,

incorrect or unreasonable use.

Use genuine spare parts only. Any damage or malfunction caused by the use of ungenuine

parts is not covered by Warranty or Product Liability.