28

28

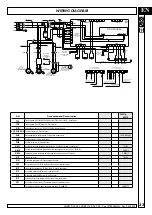

NOBEL 75 E DV

B

A

MAX

MIN.

C

B

A

MAX

MIN.

C

E

G

G1

F 1

G2

F

E

G

G1

F 1

G2

F

8

NOBEL 75 E DV

NOBEL DV 45-55

NOBEL DV 45-55

9

EN

REPLACING THE OIL FILTER

(Fig. 8)

With the compressor stopped, remove the front panel.

This operation must be carried out with the tank not pressurised.

Alarm signal.

At each change replace also the oil filter

E

, unscrew the old filter

and replace it. Always apply some oil on the edge of the filter

and on the seal before refitting manually the filter.

REPLACING THE SEPARATOR FILTER

(Fig. 8)

Bleed all air.

•Loosen all hose connections positioned on oil separator upper

flange.

•Remove flange

F1

fastening bolts

F

and lift the oil separator

filter unit using adequate lifting equipment.

•Replace oil separator filter

G

and gaskets

G1

and

G2

.

•Re-insert the components in the tank paying attention to correct

positioning of the gaskets

G1 - G2

.

•Tighten bolts in a cross sequence. Be sure to tighten bolts

evenly and re-connect all connections.

REPLACING THE OIL

(Fig. 9)

When the compressor is hot - above 70 °C, replace the oil.

Alarm signal

• Remove the front panel

• Connect the drain hose provided to cock

B

located at the base

of the separator tank.

• Unscrew the plug from hole

A

, open the cock and allow the oil

to drain in to a container until draining is complete.

• Close cock

B

and withdraw the hose.

• Refill with new oil using hole

A

(for the quantity, see the

“Technical Data” paragraph) and refit the plug.

• Start up the compressor and allow to function for 5 minutes,

and then shut it down. Discharge all of the air and wait 5 minutes

before controlling the oil level. Top up, if necessary.

THE EXHAUSTED OIL IS HIGHLY POLLUTANT!

For its

disposal comply with the current laws on environmental

protection.

• The oil in the original equipment is FSN Original Oil in the

following list:

Description

Type of oil

RotEnergyPlus

46cST

Synthetic lubricant ISO 46 for industrial use

RotEnergyFood

46cST

Synthetic lubricant ISO 46 for foodstuff use

RotarECOFLUID

46cST

Mineral lubricant ISO 46 for industrial use

A label attached to the compressor tank indicates the exact type

of oil used before first installation.

You are advised to use that type of oil in all the oil changes

planned for ordinary maintenance (for the time intervals, refer

to the maintenance table).

In the case of changing the type of oil, operate only for the

complete replacement. NEVER MIX DIFFERENT TYPES OF

OIL.

In this case, change also the oil filter and the separator filter.

MAINTENANCE

STORM 38 VS - Cod.197DD9910 - Rev.2 01/2016

NOBEL DV 45-55_NOBEL 75 E DV CSA - Cod.197EE0696ML - Rev.0 02/2020