GB

Make sure that the saddle is fully lowered and that the pump piston is fully depressed.

Remove the oil filler screw on the right side and refill the oil until 5 mm to filler hole, reinstall the oil filler screw.

1. Make sure that the saddle is fully lowered and that the pump piston is fully depressed.

2. Close the oil control valve.

3. Remove the oil filler screw on the right side , and drain the fluid into a suitable container.

4. Refill the oil until 5 mm to filler hole, reinstall the oil filler screw.

5. Open the oil control valve.

A periodic coating of light lubricating oil to pivot points, axles and hinges will help to prevent rust and assure that wheels and pump assemblies

move freely.

When used on a daily basis, the air pump should be internally lubricated before each use. Use only good quality air tool lubricant. If no inline

oiler is used, pour a teaspoon of air tool oil into the inlet of the air control valve. Simply operate the jack using the air feature in order to fully

distribute the oil.

1.

2.

1.

2.

3.

4.

5.

1.

2.

MAINTENANCE

IMPORTANT :

Use only a good grade hydraulic jack oil. Avoid mixing different types of fluid and

NEVER

use brake fluid, turbine oil, transmission

fluid, motor oil or glycerin. Improper fluid can cause premature damage of the jack and the potential for sudden and immediate loss of load. We

recommend Mobil DTE 13 or equivalent.

Adding Oil

Changing Oil

For best performance and longest life, replace the complete fluid supply at least once a year.

NOTE :

Dispose of hydraulic fluid in accordance with local regulations.

Lubrication

Cleaning

Periodically check the ram for signs of rust or corrosion. Clean as needed and wipe with an oily cloth.

NOTE :

Never use sandpaper or abrasive material on these surfaces !

Storage

When not in use, store the jack with the pump piston and ram fully retracted.

3

Summary of Contents for 24213

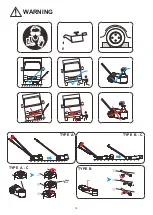

Page 14: ...WARNING TYPE B C TYPE A TYPE A C TYPE B 14...

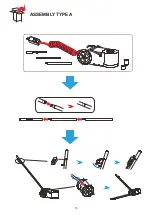

Page 15: ...ASSEMBLY TYPE A 15...

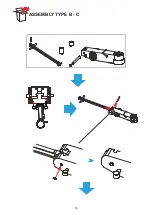

Page 16: ...ASSEMBLY TYPE B C 16...

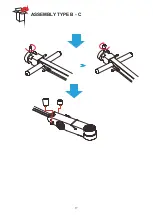

Page 17: ...ASSEMBLY TYPE B C 17...

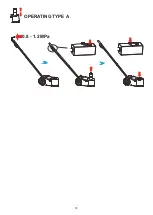

Page 18: ...OPERATING TYPE A 0 8 1 2 MPa 18...

Page 19: ...OPERATING TYPE B C 0 8 1 2 MPa 0 8 1 2 MPa 19...

Page 20: ...2018 09...