Release Valve Knob

Saddle

Tilt Adjustment

Knob

Position

Handle

Oil Filler Plug

(not shown)

Caster

Pump Handle

Chain

Handle Sleeve

Lift Arm

Grease Fitting Nipple

Release Valve Knob

Saddle

Tilt Adjustment Knob

Oil Filler Screw

Caster

Pump Handle

Chain

Handle Sleeve

Lift Arm

3

ASSEMBLY

Little or no assembly is required. Refer to Figures in

the manual for details in understanding the assembly

and the components of your product.

OPERATION

Raise saddle:

1. Locate and close release valve by turning knob

clockwise firmly, then pump the pump handle until

the load is contacted.

2. Follow vehicle manufacturers recommended proce-

dures for removing the load as outlined in vehicle

service manual or repair guide.

3. Secure load with provided chains. Ensure load's

center of gravity is centered on the saddle and load

is stable before moving jack.

Lower saddle:

Caution!

Be sure all tools and personnel are clear

before lowering load. Dynamic shock loads are created

by quickly opening and closing the release valve as the

load is being lowered. The resulting overload may

cause hydraulic system failure.

1. Slowly, gently turn the release valve knob

counterclockwise,

never more than 1/2 full turn

until the load is completely lowered.

2. Immediately transfer the load to an appropriate

repair fixture.

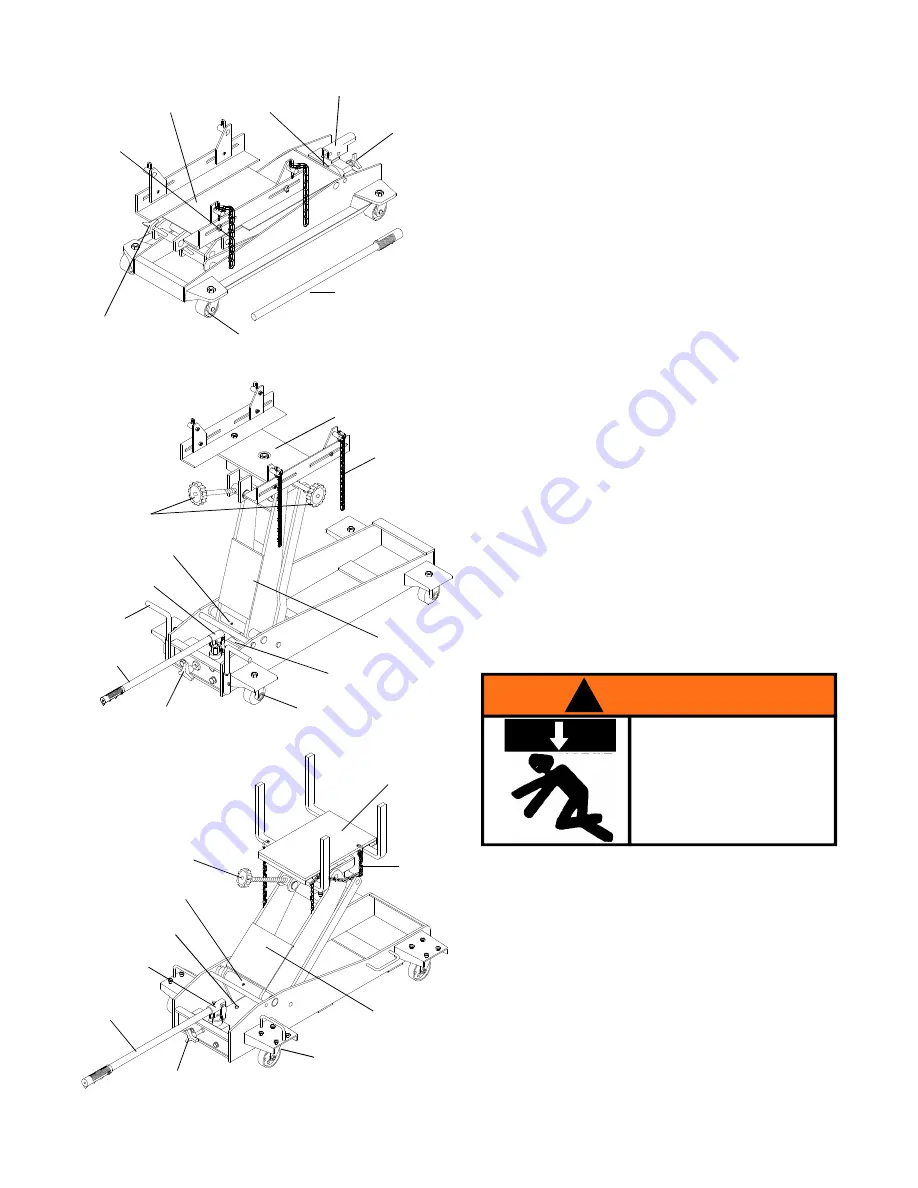

Figure 1 - Model 41100 Components

41100-M0

Release Valve

Knob

Saddle

Tilt Adjustment

Knob

Oil Filler Plug

(not shown)

Caster

Pump Handle

Chain

Handle Sleeve

Figure 2 - Model 42000 Components

Figure 3 - Model 43000 Components

Grease Fitting Nipple

To avoid crushing and related

injuries:

NEVER work on, under or

around a load supported only

by a jack. Immediately

transfer the load to an

appropriate work station.

!

WARNING