Using This Quick Start Manual

Use this Quick Start Manual to set up your Process Meter and begin

operation. Information is provided on how to:

• Connect ac power

• Set basic options for operation

Connect the sensor

• Scale the meter.

Features with

are for the “B” version which has three-color

programmable “Big” LED display - All segment characters shown are for

the “B” version.

IMPORTANT:

For complete information on all setup options, please

refer to the Operator’s Manual.

This Quick Start Manual includes specific configuration

parameters for transducers with an output range of 4–20 mA

and 24 V excitation. Other sensor types may require different

parameters or additional ones. When this is the case, we refer

you to the Operator's Manual for detailed instructions.

Safety Consideration

This device is marked with the international Caution symbol.

The instrument is a panel mount device protected in accordance with

2014/35/EU

, electrical safety requirements for electrical equipment for

measurement, control and laboratory.

Remember that the unit has no

power-on switch. Building installation should include a switch or circuit-

breaker that must be compliant to IEC 947-1 and 947-3.

SAFETY:

• Do not exceed voltage rating on the label located on the top of the instrument

housing.

• Always disconnect power before changing signal and power connections.

• Do not use this instrument on a work bench without its case for safety

reasons.

• Do not operate this instrument in flammable or explosive atmospheres.

• Do not expose this instrument to rain or moisture.

EMC:

• Whenever EMC is an issue, always use shielded cables.

• Never run signal and power wires in the same conduit.

• Use signal wire connections with twisted-pair cables.

• Install Ferrite Bead(s) on signal wire close to the instrument if EMC problems

persist.

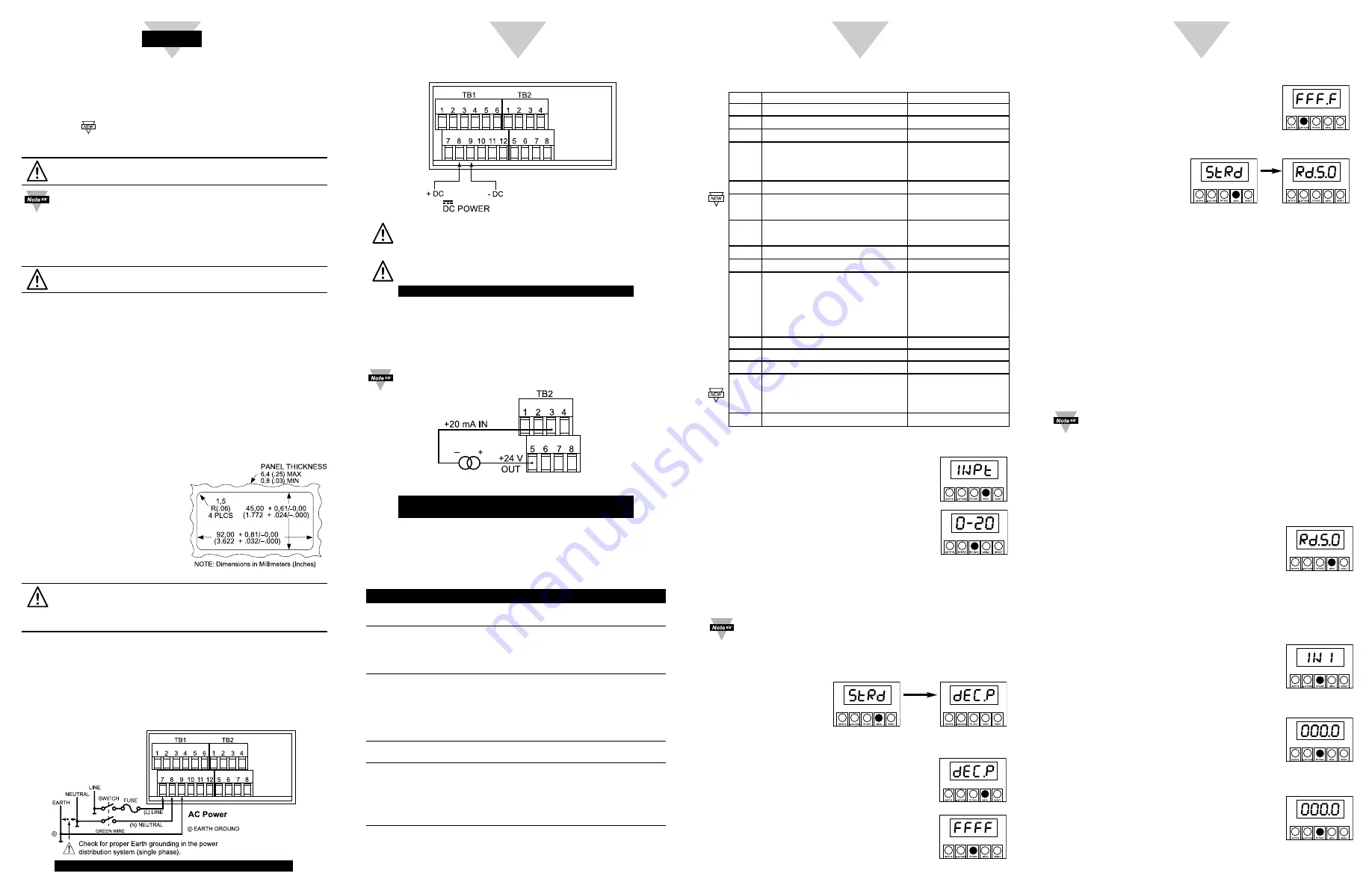

Mount the Unit

1. Cut a panel opening using the dimen-

sions shown to the right.

2. Position the unit in the opening, making

sure the front bezel is flush with the

panel.

3. Install retaining clips on both sides of

the meter and tighten against the panel.

Wiring

Warning: Do not connect AC power to your device until you

have completed all input and output connections. This device

must only be installed by a specially trained electrician with

corresponding qualifications. Failure to follow all instructions

and warnings may result in injury!

1. Remove the panel at the back of the unit.

2. Locate the TB1 connector.

3. Insert the correct wire in each terminal as shown in the following figure

and tighten the lockdown screws.

4. Tug gently on the wires to verify the connections.

External Fuse Required:

Time-delay, UL 248-14 listed Time-lag, IEC 127-3 recognized

175 mA (115 Vac line)

125 mA (115 Vac line)

80 mA (230 Vac line)

63 mA (230 Vac line)

AC Powered Unit Connections

START HERE

Wiring

(continued)

When using DC power, do not use internal excitation or Isolated

Analog Output for high color brightness. For low or medium

brightness, internal excitation is limited to 24 V @ 25 mA; 5 V, 10

V, 12 V @ 35 mA.

In order to maintain the same degree of protection as the AC units,

always use a Safety Agency Approval DC source with the same

Overvoltage Category and Pollution Degree.

DC Powered Unit Connections

Connect the Sensor

1. Locate the TB2 connector on the rear of the unit.

2. Attach the sensor wires and tighten the lockdown screws.

The diagram below shows the wiring for 4–20 mA sensors with internal

excitation.

Refer to the Operator’s Manual for setup requirements for other

sensor types.

Current Input Connections (4–20 mA)

with Internal Excitation

3. Tug gently on the wires to verify the connections.

4. Replace the panel at the back of the unit.

Using the Configuration Menu

To configure the meter, you use the buttons on the front panel.

To:

Take This Action:

Display the

Press the

MENU

button. The first function

Configuration Menu

on the menu,

INPT

, displays.

Select a submenu

1.

Press

MENU

until the function you

function

want is shown.

2.

Press

/TARE

.

The information you can change flashes.

Select a value

1.

Press

/MAX

to display the option

for that submenu

you want.

function

2.

Press

MENU

to store it.

STRD

quickly flashes, indicating that

the selection has been stored in memory.

Then the next menu function displays.

Go back to previous

Press

RESET

once.

menu function

Exit the

Press

RESET

twice. The unit displays

Configuration

RST

as it reinitializes. When a numeric

Menu

value displays, the unit is in run mode.

(Optionally, you can press

MENU

to

move through all the menu functions

until the unit reinitializes.)

2

3

4

To Set the Decimal Point

(continued)

3. Press

/MAX

to move the decimal point to the

desired location. The choices are

FFFF

,

F.FFF

,

FF.FF

, and

FFF.F

.

4. Press

MENU

to select the decimal point position shown. The

unit displays:

To Scale the Meter

You can scale the meter in one of two ways:

1. With a known load — This method uses input (load) information

sent from another device such as a scale or a simulator for

voltage or current.

2. Without a known load — This involves calculating the load

based on transducer specifications and manually entering it to

the meter.

For both methods, you must first identify the minimum input load

IN!1

and the corresponding display reading you want

RD!1

. Then

you identify the maximum input load

IN!2

and its corresponding

display reading

RD!2

.

The decimal point is for display purposes only — you set it

where you want it to display for your application.

When entering

IN!1

and

IN!2

values, ignore any decimal

point on the display. However, you must enter

RD!1

and

RD!2

values with the decimal point in the desired position.

Scaling With Known Loads

To identify the minimum known load (

IN!1

and

RD!1

):

1. If it's not already shown, press

MENU

until the unit displays:

2. Apply the minimum known load (0%).

3. Press

/TARE

. The unit displays:

4. Press

/TARE

again. The unit displays the

last setting for

IN!1

.

5. Press

/TARE

again. The unit displays the

actual reading being received from the

sending device.

MENU SUBMENU

/TARE

DESCRIPTION

INPT 100M

,

±50M

,

!10V

,

!±5V

,

0-20

* Input

DEC.P FFFF

*,

F.FFF

,

FF.FF

,

FFF.F

Decimal Point

RD.S.O IN!1

,

RD!1

,

IN!2

,

RD!2

Scale and Offset

RD.CF R.1=T

*,

R.1=N

Reading Configuration

R.2=0

,

R.2=1

,

R.2=2

,

R.2=3

,

R.2=4

*

R.3=F

*,

R.3=U

COLR GRN

,

RED

,

AMBR

Display Color

S1.CF S.1=A

*,

S.1=B

Setpoint 1 Configuration

S.2=U

*,

S.2=L

S2.CF S.1=A

*,

S.1=B

Setpoint 2 Configuration

S.2=U

*,

S.2=L

S1.DB 0003

*

Setpoint 1, Deadband

S2.DB 0003

*

Setpoint 2, Deadband

OT.CF O.1=E

*,

0.1=D

Analog Output

O.2=C

*,

0.2=V

Configuration

O.3=A

*,

0.3=P

O.4=D

,

0.4=R

O.5=F

,

0.5=H

P.BND 0000

shown if 0.3 = P

Proportional Band

M.RST 0000

shown if 0.3 = P

Manual Reset

OT.S.O RD!1

,

OUT1

,

RD!2

,

OUT2

Output Scale & Offset

LK.CF RS=E

*,

RS=D

Lockout Configuration

SP=E

*,

SP=D

L3=0

*,

L3=1

BRIT M.BrT

,

.BrT

,

H.BrT

Display Brightness

* Factory Default Settings

To Set the Input Type

1

. Press

MENU

until the unit displays:

2. Press

/TARE

. The unit displays:

3. For this application you want

0-20

. If

0-20

is not displayed,

press

/MAX

until it appears. Other choices are

100M

,

50M

,

10V

and

5V

.

Refer to the Operator's Manual for more information on

changing ranges.

4. Press

MENU

to select the sensor shown. The meter displays the

next menu item. If you changed input type, the meter displays:

To Set the Decimal Point

1. If it's not already shown, press

MENU

until the

unit displays:

2. Press

/TARE

. The unit displays:

Using the Configuration Menu

(continued)

DEVICE