5.

OPERATING INSTRUCTIONS

5.1

Preparation and Warm Up

It is assumed that the Mass Flow Controller has been correctly installed and thor-

oughly leak tested as described in section (2). Shut the flow source OFF. Apply

power to the unit via the 15-pin “D” connector. Before connecting the power sup-

ply check the controller power supply requirements label located on the controller

back cover. If the power supply requirements label states that power supply

requirement is 12 Vdc, do not connect the power supply with voltage above 15

Vdc. Exceeding the specified maximum power supply voltage limit will result in

device permanent damage. Allow the Mass Flow Controller to warm-up for at

least 15 minutes.

During initial powering of the FMA 5400A/5500A transducer, the flow output sig-

nal will be indicating a higher than usual output. This is indication that the FMA

5400A/5500A transducer has not yet attained it's minimum operating tempera-

ture. This condition will automatically cancel within a few minutes and the trans-

ducer should eventually zero.

If after the 15 minutes warm-up period, the display still indicates a reading of less

than ± 3.0 % of F.S., readjust the ZERO potentiometer [R34] through the access

window. Before zero adjustment to temporarily disconnect the gas source, to

ensure that no seepage or leak occurs in to the meter.

11

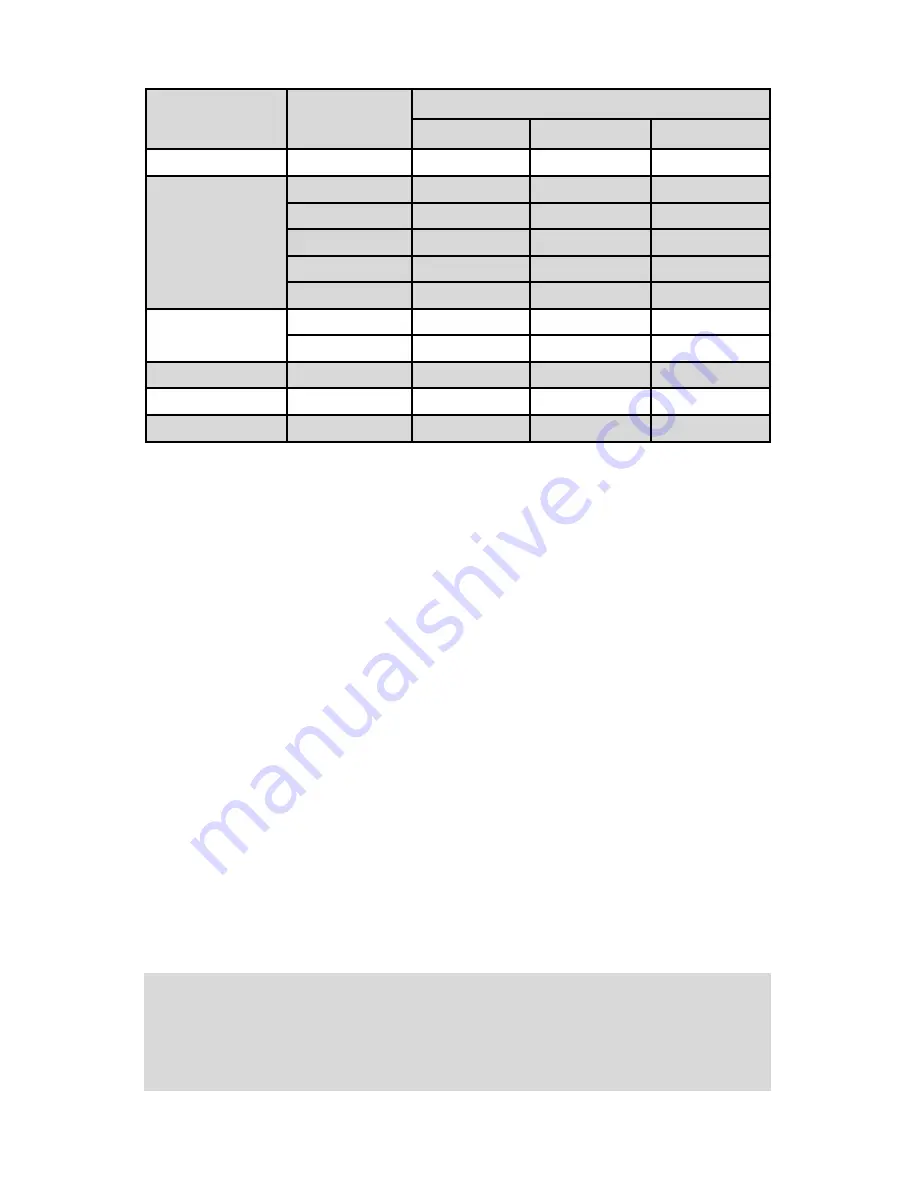

TABLE I

PRESSURE DROPS

MAXIMUM FLOW

RATE SERIES

FLOW RATE

[liters/min]

MAXIMUM PRESSURE DROP

[mm H

2

O]

[psid]

[mbar]

10 L/min

up to 10

720

1.06

75

50 L/min

15

2630

3.87

266

20

1360

2.00

138

30

2380

3.50

241

40

3740

5.50

379

50

5440

8.00

551

100 L/min

60

7480

11.00

758

100

12850

18.89

1302

200 L/min

200

7031

10.00

690

500 L/min

500

8437

12.00

827

1000 L/min

1000

10547

15.00

1034

CAUTION: Adjusting Zero Reading more than ± 3.0% F.S. from the

factory settings may affect device calibration accuracy. If such adjustment

is required it is recommended to perform controller recalibration to pre

serve device accuracy.