OIL-HYDRAULIC PRESSES WITH TWO UPRIGHTS

OPERATION AND MAINTENANCE MANUAL

30

6.9.10

OPERATION WITH AUTOMATIC FEEDER

The press is electrically pre-arranged to be interfaced with a standard sheet metal feeder.

If the model of the automatic feeder to be interfaced with the press is already known at the time of the order, the

customer service of Omera S.r.l. will be glad to supply the assembly drawing of the machine together with the

personalised interface connection diagrams. In this case, to carry out the electrical connections of the two

machines it will only be necessary to remove the by-pass plug from connector

“X60A”

on the press electric

board and insert the interface plug attached to the automation.

If not clearly stated in the supply agreement, Omera S.r.l. will not be held responsible for the installation of the

automatic feeder at customer’s factory.

As a consequence, the supplier of the automatic feeder will be held responsible for the interface of the

automatic feeder with the press supplied by Omera. The interface operation shall be performed according to the

98/37/CE

.

To this end, please note the following fundamental principles:

1. Consult the instruction manual of the automatic feeder paying particular attention to the installation

procedures and to the safety rules for the operator;

2. In the case of lateral supply, the press side barriers should be modified/adapted to new application

conditions of the press. To this end, we recommend carrying out any modifications in compliance with the

European harmonised EN-294 standard “Safety of machinery - Safety distances to prevent danger zones

being reached by upper limbs”.

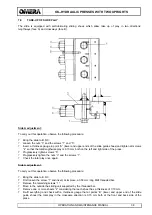

1. In the case of supply from above or behind the press, the guards supplied can be de-activated using the

53SA20 and 53SA21 selectors to permit the passage of the loading unit from one side and of the drawn

piece from the other side.

The guards will be secured by means of special barriers constructed in compliance with the current

standards (EN292-2, EN294, EN953, EN1088);

3. When performing the lateral or front loading, the drawn piece can be ejected from the die during sheet metal

loading phase. In this case the user shall take appropriate technical steps to prevent the drawn piece just

unloaded from causing injures to personnel near the machine;

4. After having completed interfacing and modification/installation of the safety grilles, the following operation

checks must be carried out before starting the machine:

- check that the safety grille opening strops the press dangerous movements;

- check that the press operation reset can take place only after having closed the safety (front and back) grilles;

- check the operation of the cycle stop buttons which interrupt the press dangerous movements.

5. To set the press to automatically operate with the sheet metal feeder, refer to programming manual of the

INDUSTRIAL PC.

6. When the press operates in single mode, with manual loading and unloading, the original adjustments must

be reset.

6.9.11

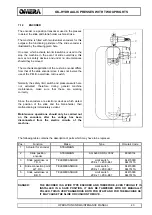

AUTOMATIC CYCLE START

If the “automatic” cycle mode has been selected, it is necessary to recall the “LINE GENERAL PAGE” on the

screen of the INDUSTRIAL PC located on the hanging push-button board of the OPI 315 press to start

continuous production and use the “AUTOMATIC CYCLE START” field relevant to the section consisting of the

OPI 315 press and the relevant automatic loader.

The same has to be performed after every cycle interruption caused by a violation of a protection barrier, or after

pressing the “EMERGENCY” or “AUTOMATIC CYCLE STOP” buttons.