MATERIAL SPEC

OlyBond500 adheres virtually all common types of insulation to a wide variety of substrates

and is compatible with and approved by most roof system manufacturers.

Approved substrates

Concrete

Lightweight concrete

Gypsum

Tectum

Most vapor barriers

Existing BUR (smooth)

Steel

Wood

Existing modified

bitumen

Approved insulation

Polyisocyanurate

High density

wood fiber

Perlite

Most cover boards

Expanded polystyrene

Foam glass

Certain extruded

boards

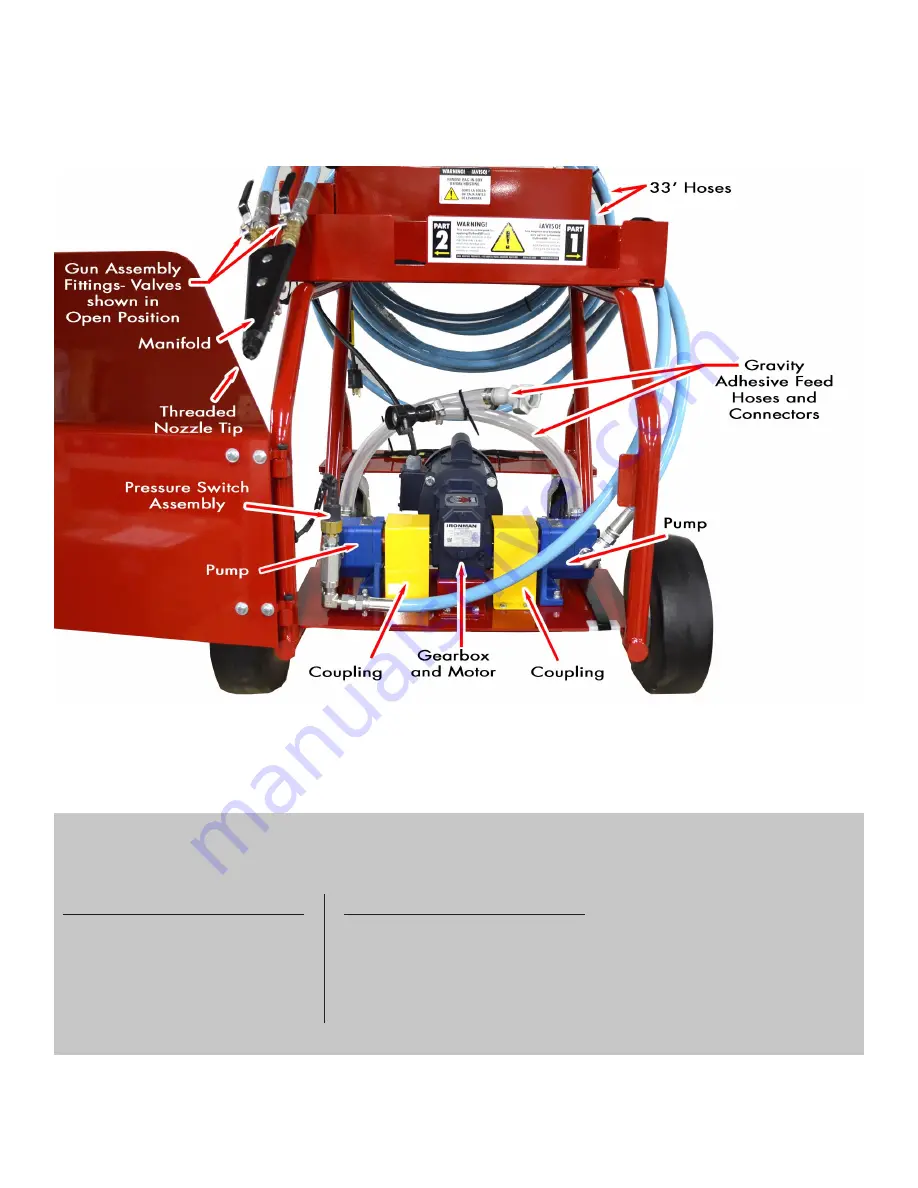

SYSTEM COMPONENTS

See the complete parts list on pages 6–7.

To determine compatibility with substrates or insulation not listed,

call 800.633.3800 or 413.789.0252.

FOR ASSISTANCE

In addition to supplying a broad array of fasten-

ers and accessories, OMG Roofing Products has

a nationwide team of field representatives who

offer services to contractors, building owners,

architects and roof consultants, including:

• pull-tests • job starts

• pre-installation application assistance

and training

For consultation or on-site assistance,

contact OMG at 800.633.3800 or

413.789.0252.

PaceCart 3 Owner’s Manual

Page 4