STEP 1:

TIGHTEN ALL FITTINGS

Fittings can loosen in transit.

Use a wrench to

check all hose

connections and tighten as

necessary.

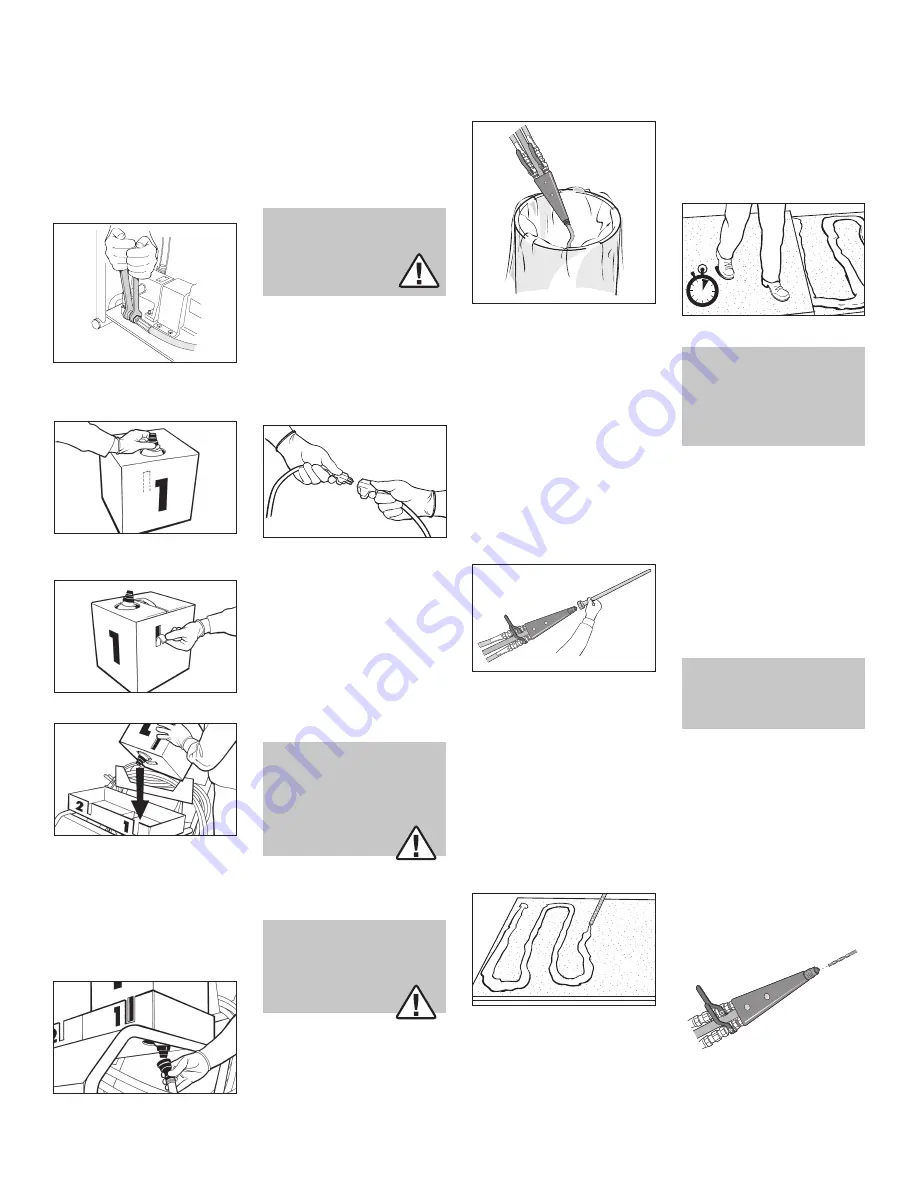

STEP 2:

INSTALL BAG-IN-BOX

Extend spout

on Part 1 & Part 2

boxes.

Open window

on each box.

Invert boxes and place in correct

trays,

aligning windows with open

slots at front of each tray.

Note

that adhesive tray color

matches the color of the nozzle on

the adhesive bag. Part 1 is black,

part 2 is gray.

Lubricate connectors

using white

lithium spray, then

connect spouts

to gravity hoses. Remove any air

from gravity hoses by squeezing and

pushing air into box.

WARNING

Connector colors must match!

Part 1A: Black to Black

Part 2B: Gray to Gray

STEP 3: CHECK POWER

SPECS, PLUG IN CART

Never run PaceCart 3 with low-

voltage power or you risk severe

damage to the motor!

The PaceCart 3 requires power

in the range of 110 to 125 volts,

15 amp. Check the power source to

be sure there is no competing equip-

ment. Using an overloaded line or an

extension cord longer than 75 feet

(23m) will diminish your power.

Ensure that the on-board voltage

meter shows ample power: i.e. 110-

125 Volts.

WARNING

If the machine stops operating

and begins to hum, turn it off

immedi ately and check

the power source.

STEP 4: PURGE GUN

TO PREPARE IT FOR USE

WARNING

The nozzle must be cleaned

before attempting to

purge the gun.

Purge the gun by running

OlyBond500 material through it

before

attaching the mix tip.

With

valves open

and the gun over

a bucket, turn on the PaceCart 3 at

the power switch. For new PaceCart

3 equipment, leave valves open and

let material run for 1 minute after

it starts to flow to purge packing

oil from pumps. For each subse-

quent use, let material flow for

30 seconds.

There should be equal

streams of Part 1 and Part 2, indi-

cating that both sides are flowing

properly. Make sure the two sides

are running evenly.

Shut valves.

STEP 5: ATTACH MIX TIP

Lubricate threads with white

Lithium spray before connect-

ing the tip. Attach the mix tip to

the gun. Immediately proceed to

step 6.

STEP 6: APPLY

ADHESIVE TO SURFACE

Open both valves completely and

dispense material

in a serpentine

pattern as shown above.

Dispense material at increments

as specified by the manufacturer.

When dispensed with a 1:1 ratio,

a chemical reaction occurs on the

substrate, and the adhesive begins

to foam.

OlyBond500 is formulated to give

roofers sufficient time (3–4 minutes)

to place the insulation boards onto

the adhesive before it reaches its

tack-free state.

CAUTION

Replace the mix tip every

time you stop. Failure to do so

may result in clogged

gun and hoses.

STEP 7: LONG TERM

SHUT-DOWN PROCE-

DURES

Always store the PaceCart 3

with the boxes in place.

• Turn off power to adhesive cart.

• Close ball valves - relieve pres-

sure from lines completely.

• Leave mix tip on.

• Keep gun pointing downward.

NOTE

For long term storage, use

OMG PCPreserver.

After long-term storage, call

OMG for service at 800.633.3800

or 413.789.0252.

STEP 8: START-UP AFTER

SHUT-DOWN

1. With machine in the "off" posi-

tion, open valves.

2. Insert supplied drill bit and rotate

by hand to clear any obstructions.

3. Clean drill bit before clearing out

the other side.

4. Attach new mixing tip when ready

to dispense.

OPERATING INSTRUCTIONS

PaceCart 3 Owner’s Manual

Page 5