AUTOMATIC CALIBRATION

The new RhinoBond Tool features “OptiWeld” automatic calibration for optimum welding.

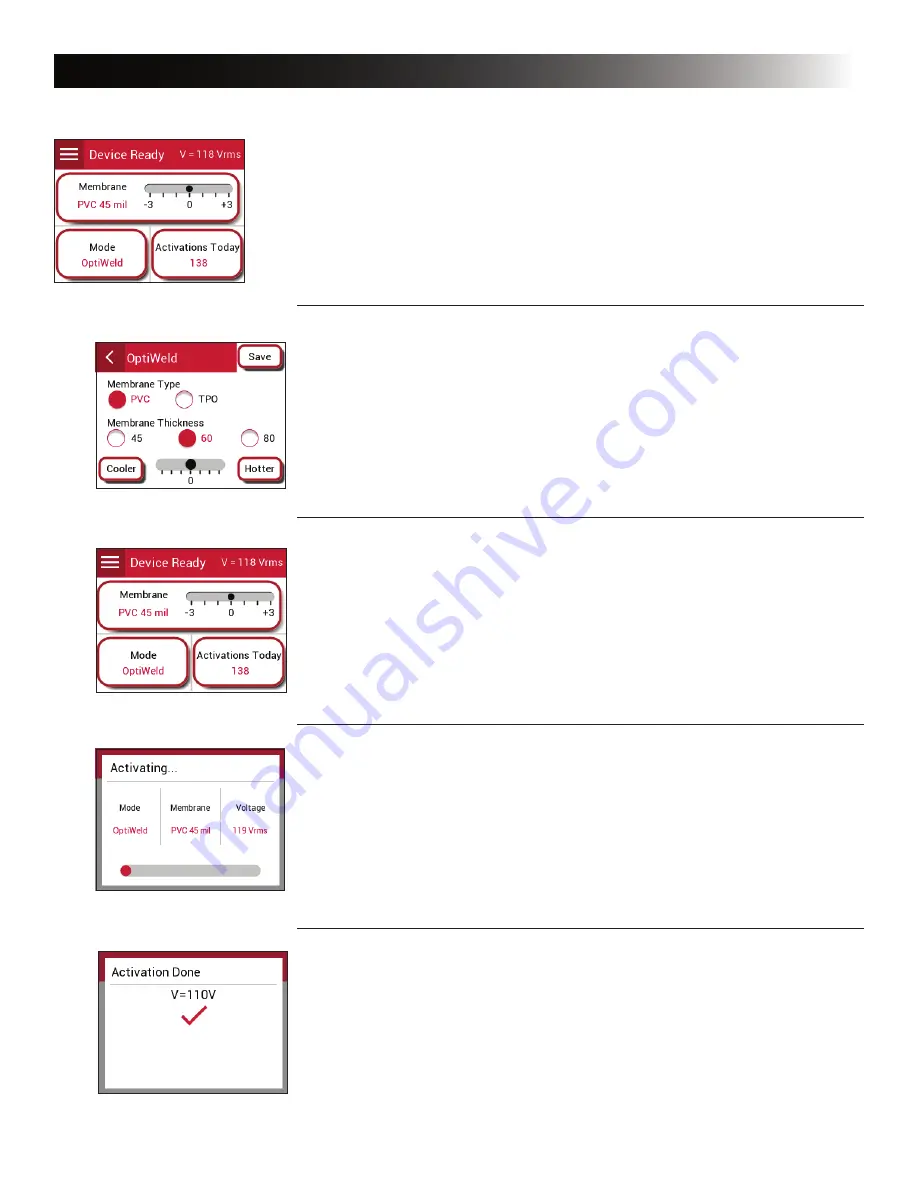

When set in OptiWeld mode, the “Mode” button displays OptiWeld. Membrane type and thickness and fine adjust settings

are also displayed. Pressing the “Mode” button allows users to toggle between “OptiWeld” and “Manual” operating mode.

Pressing the “Membrane” button allows users to adjust the “OptiWeld” settings.

From the “Device Ready” screen, press the “Membrane” button and select the type (TPO or PVC) and thickness

(45, 60, 80 mil) of the membrane you are installing.

Press “Save” to return to the “Device Ready” screen.

Activations Log:

The “Activation Today” button displays the number of weld cycles performed on that calendar

day. Pressing this button will open the tool log, where a history of weld cycles can be reviewed.

Power Display:

The Power Display shows the line voltage the tool is receiving from the power source.

The tool requires a minimum of 100 volts to operate effectively.

Menu:

Pressing this button will open the menu screen.

Once the tool settings are complete and accurate for the membrane type and thickness being installed, the tool is ready

to weld.

To activate the tool, place the tool over the plate by aligning the target area on the base of the tool directly over the

plate to be welded. The tool should be centered over the RhinoBond plate for an optimum weld.

When the tool is aligned over the plate, press the activation button, also called the trigger, located on the handle of

the tool.

The display will indicate the tool is in activation mode and show a progress bar.

When the weld is complete, the RhinoBond tool will emit a beep, provided that the sound is turned on

(see Page 11), and display the “Activation Done” screen.

The screen will automatically return to the “Device Ready” screen for the next weld.

RhinoBond Owner’s Manual - Page 9