Cod. 710.0167.01.00 Rev02

– 10.2019

© Copyright 2019 OMI Srl - All rights reserved

6

– 12

3.1.1 KEYS FUNCTION

TEST:

When

pushed for 3 sec. during normal operation, it activates the condensate drain.

(Not used on No loss condensate drain)

SET:

When pushed and released during normal operation, it displays the parameter C1.

When pushed for 10 seconds, it allows to enter the C8 and C9 condensate drain parameters programming menu (see

relevant table).

When pushed after having set new configuration values, it stores the applied modifications.

DOWN:

When pushed while setting the drain set point, it decreases the displayed value of one unit per second, during the

first 10 seconds, than of one unit every 0,1 sec.

When pushed for 10 seconds during normal operation, it starts an automatic test cycle of the controller.

UP:

When pushed while setting the drain set point, it increases the displayed value of one unit per second, during the first

10 seconds, than of one unit every 0,1 sec.

ON / OFF: Pressed,

it activates or deactivates the dryer. When the dryer is deactivated, the display shows OFF.

NOTE: when the controller is in the OFF position, some parts of the dryer may still be energized. Therefore, for

safety purposes, disconnect the electrical power before performing any operation on the machine.

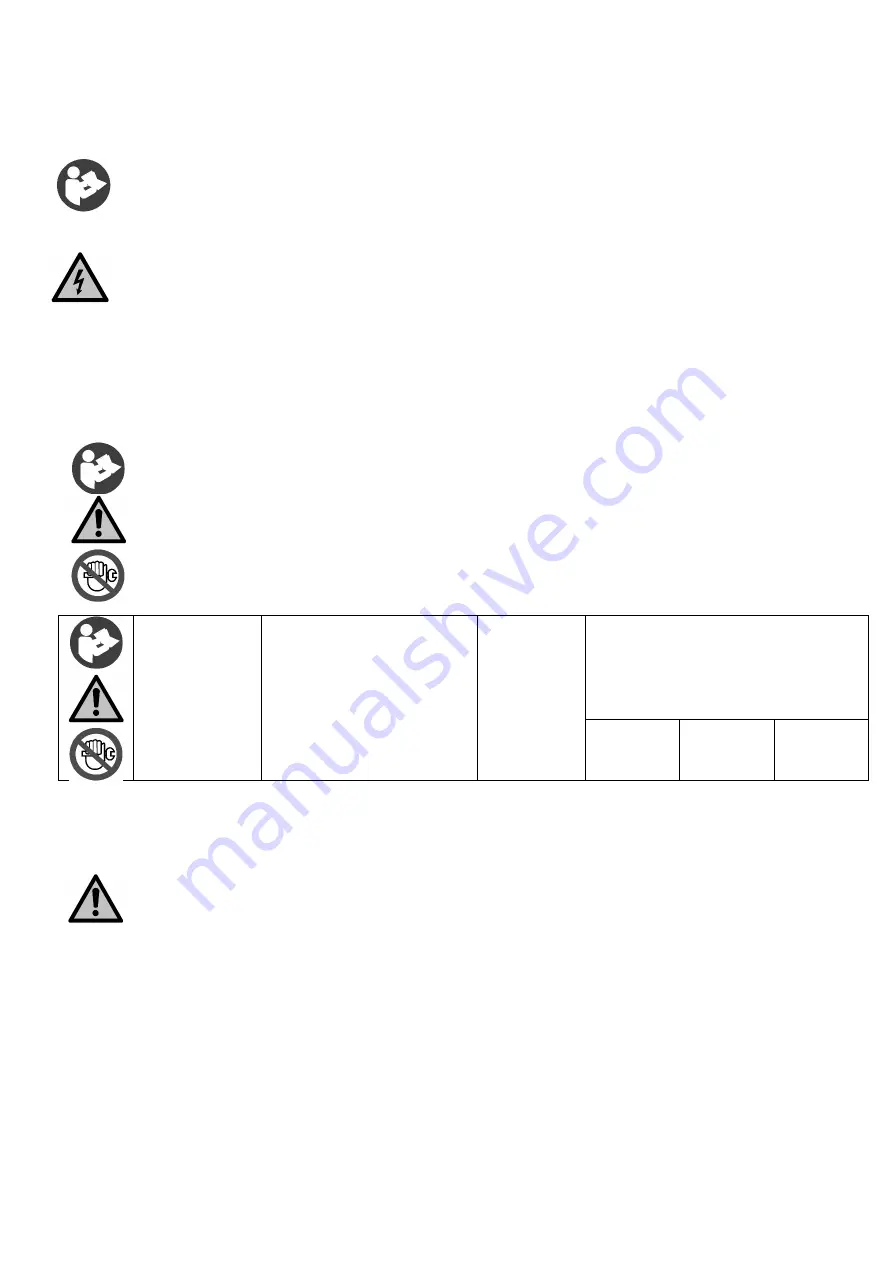

3.1.2 CONDENSATE DISCHARGE PARAMETERS PROGRAMMING

Push the SET key for 10 seconds to enter the parameters configuration menu: the display will show in sequence the

set point value, the code of the first modifiable parameter (C8) and its value).

Only if strictly necessary, use the UP and/or DOWN keys to change the displayed parameter value.

Press the SET key to store the previously changed parameter value or to browse the parameters without changing

them.

15 seconds after the last performed operation, the controller will return automatically to the normal operation mode.

PARAMETER

DESCRIPTION

RANGE

DEFAULT SET VALUE

C8

Delay between condensate

discharges

1 ÷ 240 (min)

1

C9

Time required for condensate

discharge

1 ÷ 240 (sec)

DD36-180

DD216

DD280-1300

1

2

3

NOTE: Changes entered for timing values will be effective only after exiting the programming, while changes to other variables

will be immediately effective.

Please remember that eventual changes to the configuration parameters of the machine could negatively affect its efficiency.

Thus, changes have to be performed by a person familiar with the operation of the dryer.

WARNING FOR USER:IT’S FORBIDDEN TO ATTEMPT TO MODIFY THE OTHER CONFIGURATION PARAMETERS

OF THE ELECTRONIC CONTROLLER WITHOUT AUTHORIZATION AND COLLABORATION OFOMI

’S

AUTHORIZED DISTRIBUTOR.