Cod. 710.0167.01.00 Rev02

– 10.2019

© Copyright 2019 OMI Srl - All rights reserved

7

– 12

3.1.3 DISPLAY INDICATIONS

The controller is capable of recognizing certain types of anomalies in the drying circuit. In such cases, a message will blink on the

display, alternated to the current dew point value.

MESSAGE

(BLINKING)

CAUSE

OUTPUTS

ACTIONS

HtA

High dew point value

(delayed alarm)

Alarm output ON

Refrig. Compressor output OFF

Fan output ON

Drain cycle standard

Resettable by switching off the

dryer.

If problem persists call your local

OMI distributor.

Ht2

Very high dew point value

(immediate alarm)

PF1

Interruption or short circuit on the

PTC probe input line

Alarm output ON

Refrig. Compressor output OFF

Fan output OFF

Drain cycle standard

Resettable by switching off the

dryer. May require replacing the

faulty probe.

If problem persists call your local

OMI distributor.

ESA

The automatic Energy saving

mode activated due to low load

Alarm output OFF

Refrig. Compressor output OFF

Fan output OFF

Drain cycle standard

No action necessary.

Automatic Reset

ES2

ASt

Activated after repeated alarms

Alarm output ON

Refrig. Compressor output OFF

Fan output ON

Drain cycle standard

Call your local OMI distributor.

Note: PF1 has priority on all other messages.

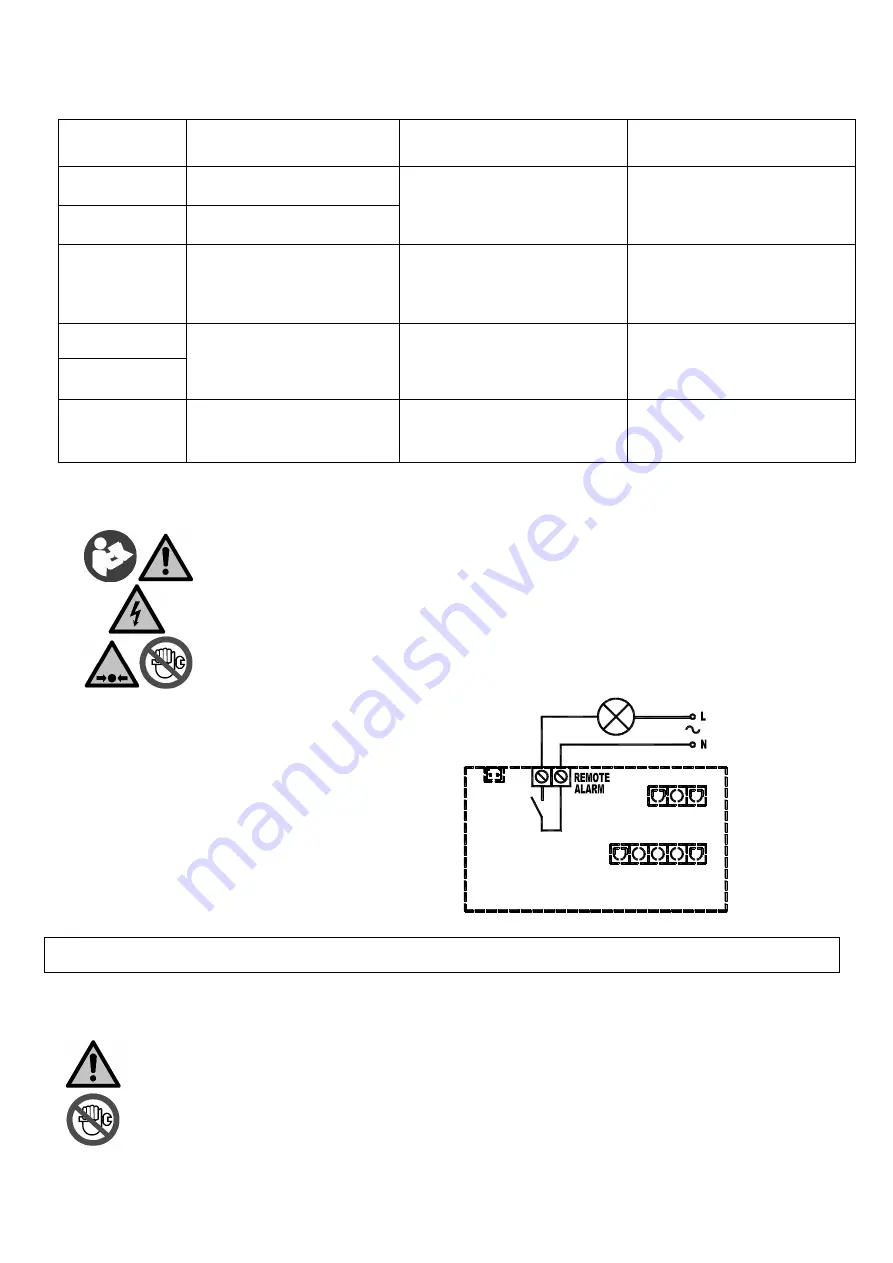

3.1.4 REMOTE SIGNALING ALARM (OPTIONAL)

The dryer control board is equipped with a dry contact for a remote alarm signal. This is normally open

contact: when an alarm is detected, this contact is closed.

Proceed as follows to activate a remote alarm output:

1. The User must review the diagram below.

2. Disconnect the dryer from electrical power supply, remove cover and left side panel.

3. Connect the alarm circuit to the terminal blocks (See PIC.2).

4.

Replace cover, left side panel and reconnect power.

Alarm Output relays electric features:

Max. 250VAC / 3A

– AC 15 (Amp. Inductive)

PIC.2

The activation of the above function is at the User’s discretion. The User will purchase all necessary installation material.

Any operation which needs access to the dryer must be carried out by qualified personnel.

3.2 BEFORE START UP

Before starting the machine, make sure that all operating parameters correspond to the nominal data.

The dryer is supplied already tested and preset for normal operation, and it doesn’t require any calibration. Nevertheless,

it’s necessary to check the operating performances during the first working hours.