Cod. 710.0167.01.00 Rev02

– 10.2019

© Copyright 2019 OMI Srl - All rights reserved

12

– 12

5. SAFETY INFORMATION

5.1 General safety instruction

SAFETY INFORMATION

This dryer has been designed and manufactured in accordance with the European safety directive

2006/42/EU

Machine Directive

2006/95/EU

Low tension Directive

2004/108/EU

Electromagnetical compatibility Directive

2014/68/EU

PED Directive

According to PED Directive, this plant is supplied with safety devices on the frigorific circuit, calibrated according to the

under mentioned specifications.

The working life of such equipments is expected between 10 and 20 years.

Any installation, use and maintenance operations must be done according to the instructions contained in this manual and

in accordance to the national rules.

Any cleaning/maintenance operation which needs access to the dryer must be carried out by qualified and export personnel

who must be aware of all necessary precautions.

The machine has been designed and manufactured to be used in conformity to the following specifications.

In case of different use of the

machine or not in conformity to this manual, the Manufacturer can’t be accused of any

responsibility.

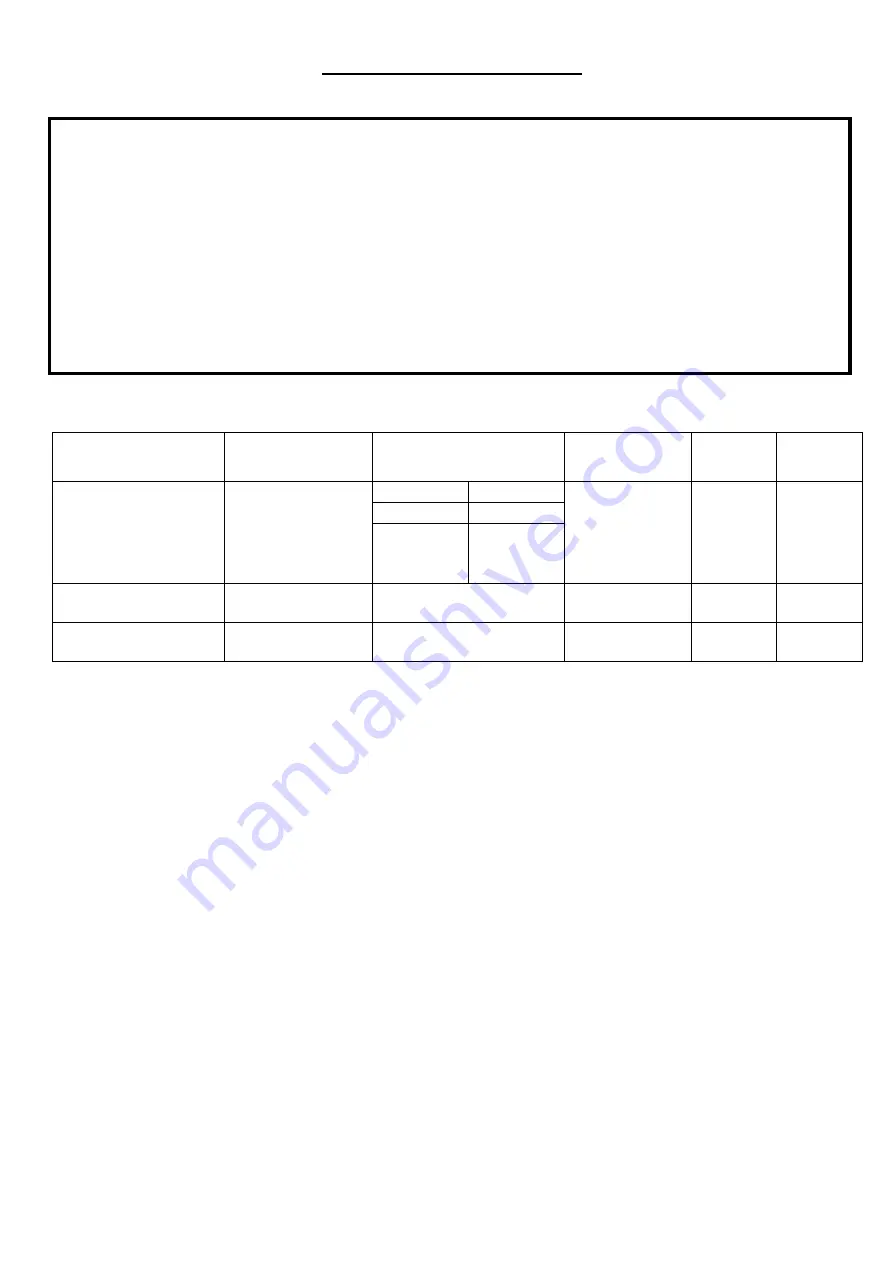

5.2 Equipment nameplate values

(Nameplate values extracted from Calculation data sheet)

Fluid

Circuit Side

Press. Max. Amm.

Safety devices set Work. Temp

Design Temp

MAWP

"PS" (bar rel)

(bar rel)

(°C)

(°C)

Freon HFC

(R507, R407c, R134a, R404a)

Ambient 55°C

Ambient 45°C

See ATTACHMENTS

TO THIS MANUAL

C) Technical data

sheet

R134a R407c

R404a, R507

Low press. -LP

20

20

min -10°

min -15°

High Press. -HP

31

31

max +120°

max +120°

High Press. WATER -HP

30

30

Compressed air

Compress. Air Side

min 0

(Customer care)

min 0°

min -15°

max. 16

max +60°

max +60°

Ambient air

Ventilation side

Atm.

( Not Appl.)

min 5°

min -15°

max +55°

max. +55°

* - Safety Pressure switch Cat IV PED, Manual reset

Welding Joints Coefficient

z

0,7

(Table 5.6-1)

Tickness allowance

c

0 mm

( For copper )

(Not required for surfaces in contact with freon - EN 14276-1)

c

1 mm

( For carbon steel )

Manufacturer design code

717.0012.01.00

Essential Safety Requirements

ON10.0010.09

Manufacturer Working Procedure

PO 08.2

Assembly classification according 2014/68/EU

See Declaration of Conformity

Evaluation Module according 2014/68/EU

See Declaration of Conformity

PED Notified Body number

See Declaration of Conformity

5.3 Information about remaining risks of the equipment

Fire:

This equipment, in accordance to EN-378-

2, isn’t supplied with freon drain safety valve.

In case of fire it is preferable to use fire extinguishers or extinction systems basically composed of powder or foam or carbon dioxide: it is possible to

cool the equipment thanks to nebulized water.

Avoid the massive use of water because, in case of freon gas leak, the chemical reaction can cause caustic effects, even if small.

In any case it is necessary to cool down the ambient and/or the equipment’s temperature and before any intervention wait until the temperature has

been reduced.

Therefore it is preferable to insert this equipment into the Fire Prevention and Factory Safety Plan.

Arrange adequate actions capable to prevent and fight the possible risk.

Dispersion of freon gas in the ambient:

the refrigerant means is toxic only if inhaled at high concentration: it is necessary to provide an adequate ventilation in the room where the equipment

is installed.

In any case check the scheme showing the values and the risk sentences.

Excessive pressure on the compressed air side:

this equipment isn’t supplied with safety devices on the compressed air side.

The safety devices on the compressed air side must be carried out by the installer.

Such devices will have to be carried out according to the applicable National Norms and to the limits mentioned in this Manual.

Ozone layer deterioration:

The adoption of HFC freon reduce to the minimum ozone layer deterioration and greenhouse effect.